1. Ultrasonic high-speed frequency vibration with 20,000-32,000 times per second

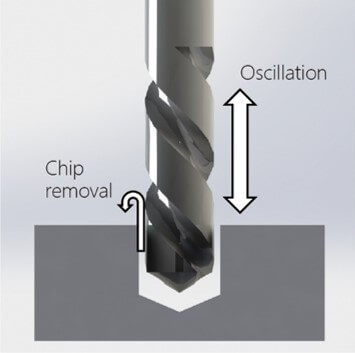

The machining technology of HIT ultrasonic tool holders is mainly used to reciprocate the tool in a fixed direction at a high-speed frequency of 20,000 to 40,000 times per second by the resonance effect. The amplitude can make the cutting removal in the machining process more effective, therefore simultaneously reducing the cutting force and chipping of hard-to-cut materials as well as optimizing the machined surface.

2. Non-contact power transmission ultrasonic processing technology

Since the ultrasonic handles contains electronic components, the power transmission method has become an essential part of the technology. HIT ultrasonic machining tool holder module utilizes the non-contact power transmission technology to transmit the electric power on the high-speed rotating tool. A patented precision actuation mechanism inside the tool holder then generates a high-frequency micro-vibration on the cutting tool edge. Neither consumables nor friction which causes tool wear do you need to worry, removing the limitation of the high spindle rotation speed advantage. Which achieves a win-win effect of stable and efficient production.

3. Automatic identification & tracking control function

With the application of automatic identification & tracking control function, No special specifications are required, the automatic resonance frequency can be applied to flexible situations. We also construct the data-library for processing advanced materials using ultrasonic vibration-assisted machining.

Contact us for complete ultrasonic machining solution.

What’s the specialties of HIT Ultrasonic Machining Module?

Application cases validated with HIT Ultrasonic Machining Module