(Figure 1. ultrasonic-assisted side milling on AISI-4140/42CrMo4 alloy steel workpiece)

(Figure 2. the original AISI-4140/42CrMo4 alloy steel workpiece)

HIT's Goal in Machining AISI-4140/42CrMo4 Alloy Steel

The goal is to enhance machining efficiency while maintaining high surface quality, and potentially improve and prolong the stability in tool life.

Ultrasonic-Assisted Machining AISI-4140/42CrMo4 Alloy Steel Results

AISI-4140/42CrMo4 Alloy Steel Side Milling : Machining Efficiency

In conventional machining, the fine grinding process was required to make sure the two milling sides are parallel.

With HIT Ultrasonic, the fine grinding process can be eliminated, and it only took one cut of side milling to complete the machining process. It allowed to save up more time from fewer setups and less manufacturing steps.

AISI-4140/42CrMo4 Alloy Steel Side Milling : Workpiece Quality

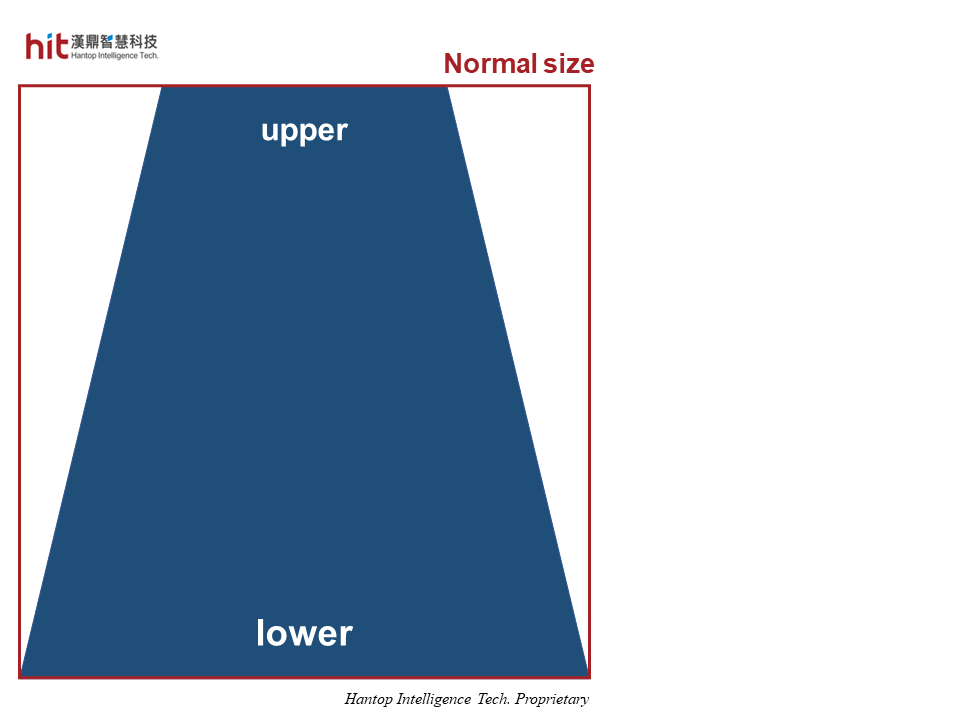

(Figure 3. the schematic diagram of AISI-4140/42CrMo4 alloy steel milling sides of the workpiece)

The inclined surfaces occurred without the assistance of ultrasonic machining (upper: 10.10mm; lower: 10.15mm).

With HIT Ultrasonic, both the upper and lower parts of the milling sides were measured 10.10mm in compliance of the normal size required by the client.

AISI-4140/42CrMo4 Alloy Steel Side Milling : Tool Life

The improvement in the stability of tool life could be seen from the workpiece quality. The inclined surface on the workpiece usually happened when there was serious tool wear, which made the tool too blunt to maintain the cutting depth.

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - the fine grinding process can be eliminated

📈 Quality - milling sides are measured to be parallel, no inclined surface

⚙️ Tool Life is stable to prevent inclined surfaces on the milling sides