Optical glass deep hole drilling:

Picture of workpeice:

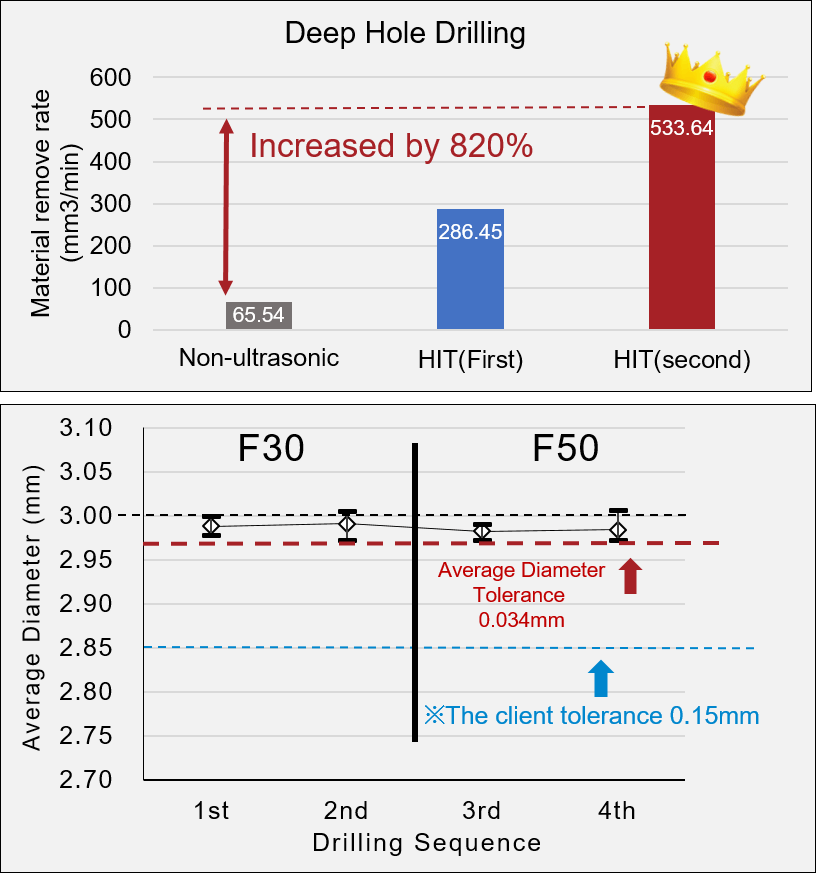

Comparison of Material remove rate:

Using HIT ultrasonic machining module can improved 8 times of efficiency (material remove rate) compared with non-ultrasonic machining.

With HIT ultrasonic machining module can also reach higher standard quality. The clients' tolerance is 0.15mm, and with HIT ultrasonic machining module, the average diameter tolerance is 0.034mm.

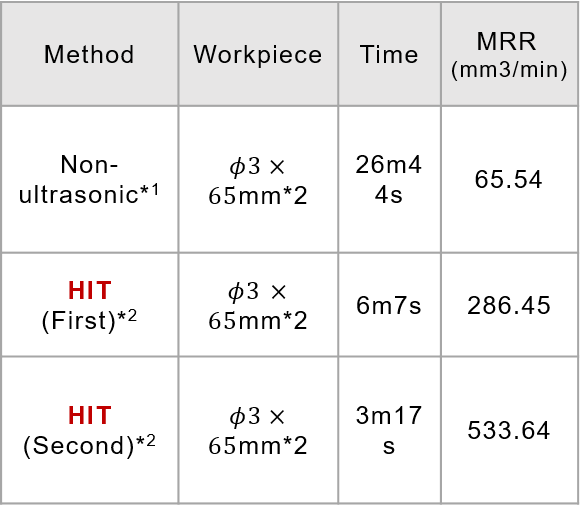

Machining Data and Comparison:

HIT Ultrasonic Module Highlights:

Compared to non-ultrasonic,

- 8 Times Drilling Efficiency

- Meets the Customer’s Requirements