Learn Ultrasonic Machining in 1 Minute 💡

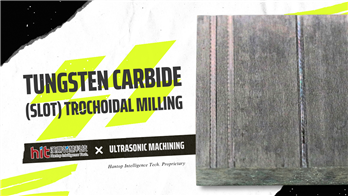

👍🏻 Machining Efficiency: 1.5x Higher |

👍🏻 Surface Quality: 1.6x Better |

👍🏻 Tool Life: 2x Longer

👍🏻 Machining Efficiency: 3x Higher |

👍🏻 Workpiece Quality: 1.4x Better

HIT utilized the ultrasonic machining module for (slot) trochoidal milling on Tungsten Carbide. The high frequency micro-vibration allows the tool to constantly lift from workpiece. This brings better inflow of cutting fluid, offering better cooling effect and easier chip and carbonized diamond powder evacuation. The reduced friction between tool and workpiece helps achieve 2x better surface quality and over 2x longer tool life.

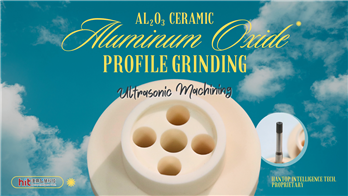

👍🏻 80% Higher Machining Efficiency | 👍🏻 3x Longer Tool Life | 👍🏻 90% Better Surface Quality

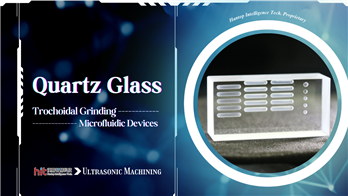

👍🏻 4x Higher Machining Efficiency | 👍🏻 75% Longer Tool Life | 👍🏻 1.5x Better Surface Quality

👍🏻 2x Higher Machining Efficiency | 👍🏻 3x Better Workpiece Quality | 👍🏻 Great Reduction in Tool Wear

👍🏻 Machining Efficiency +5.5x | 👍🏻 Tool Life +5x | 👍🏻 Greatly Reduced Burrs

HIT utilized ultrasonic machining module for micro-channel trochoidal machining of quartz glass. The high frequency micro-vibration helped reduce cutting forces, which made the max. size of edge-cracks around the micro-channels 2x smaller than that without ultrasonic. Easier inflow of cutting fluid brought better particle flushing, resulting in the reduction of tool wear.

HIT utilized ultrasonic machining module for (helical) circular ramping of SiC (silicon carbide). The high frequency micro-vibration helped reduce cutting forces, which helped improve surface roughness by 72%. Ultrasonic-assisted grinding mechanism also brought better particle flushing, preventing the tool from ceramic dust accumulation.

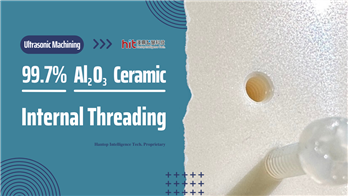

HIT utilized ultrasonic machining module for internal threading on 99.7% Aluminum Oxide (Al2O3). The high frequency micro-vibration of HIT ultrasonic allowed for intermittent contact between the tool and workpiece, achieving better chip and cutting heat removal. This greatly reduced tool wear and ensured complete profile of M2 internal thread dimension.

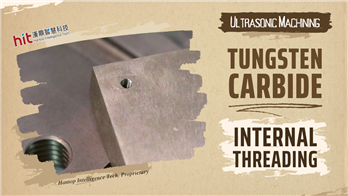

HIT utilized the ultrasonic machining module for the internal threading on Tungsten Carbide. The high frequency micro-vibration of HIT ultrasonic-assisted machining technology allowed for intermittent contact between the tool and workpiece, achieving better chip and cutting heat removal. This greatly reduced tool wear and ensured the complete profile of M2 internal thread under 3 times higher machining efficiency.