HIT utilized the ultrasonic machining module for the micro-drilling on SiC (Silicon Carbide). HIT ultrasonic-assisted machining technology greatly enhanced the hole quality. The size of edge-cracks is reduced by 53%, compared to that without ultrasonic.

HIT utilized the ultrasonic machining module for the deep hole drilling on S45C Meidum-Carbon Steel with gun drill. With the aspect ratio being 25x, under the same rotation speed, the entire machining efficiency was enhanced 2 times higher than that without ultrasonic. The high frequency micro-vibration of HIT ultrasonic-assisted machining technology allowed for intermittent contact between the tool and workpiece, achieving better chip and cutting heat removal with only 40bar of coolant through spindle (CTS). The size of chips was shrank by 91%, which greatly reduced tool wear.

HIT utilized the ultrasonic machining module for Titanium Alloy (Ti-6Al-4V) side milling. The ultrasonic-assisted machining technology allowed for 3 times faster of the cutting speed, resulting in the increase in feed rate and machining efficiency. The high-frequency ultrasonic micro-vibration reduced the cutting force and cutting heat, which ensured better surface quality and improved the tool life.

HIT utilized the ultrasonic machining module for the micro-drilling 99% Aluminum Oxide (Al2O3) ceramic. HIT greatly enhanced the machining efficiency by 60%, and maintained high quality workpieces with no edge-cracks or burrs on the drilling holes by sight.

HIT presents ultrasonic machining module introduction video. High speed frequency vibration, non-contact power transmission technology, flexible applications.

Hantop Intelligence Tech. presents ultrasonic machining module introduction video. High speed frequency vibration, non-contact power transmission technology, flexible applications.

Faced with the difficulty of processing new materials , Hantop Intelligence Tech. developed ultrasonic machining modules as the best solution.

HIT ultrasonic machining module applications of SiC micro drilling and parts machining

Effectively enhance 2 times of efficiency and 3 times of tool life.

HIT ultrasonic machining module applications of Alumina ceramic parts machining

Enhance 3 times of efficiency, 3 times of tool life

Multiple Factors: Efficiency × Tool life

And you gain over 9 times of profit simply add-on HIT Ultrasonic Machining Module!

HIT ultrasonic machining application---zirconia back plate machining

Both prolongs tool life to 300% and reduces process time to 50%.

High frequency vibrations prevent micro-cracks AND enhancing quality.

Add on module type can be easily installed on various CNC machine.

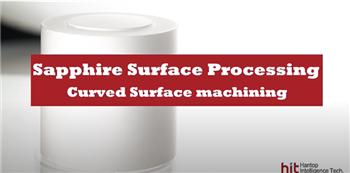

Materials: Sapphire

Features: Curved Surface Machining

Difficulties:

Severe Edge-Cracks caused by extreme hardness

Tight tolerances quality demands lead to short tool life and low efficiency.

Highlights of HIT Ultrasonic Machining Module:

Enhances 200 % of efficiency compared to Conventional CNC—

High Frequency Ultrasonic Vibrations enlarges materials removal rate (MRR)

Maintain quality in hi-efficiency processing

Reducing edge-cracks via Lowering the cutting force into each slight vibration

For More Details, Welcome to our applications:

https://www.hit-tw.com/advantagedetails.aspx?id=121

HIT provides the most efficient ultrasonic machining technology for new materials machining. Our module can be easily installed on your current CNC machine. And with ultrasonic hi-frequency vibrations, the cutting resistance will be reduced 40%, and it could enlarge material removal and enhance efficiency. The video will showcase the development of HIT as well as demonstration of HIT ultrasonic module in SiC drilling.

At present, we have provided USM to US, Korea, Japan, Singapore, Taiwan, etc., and validated with 26 clients spread worldwide of various industries including aerospace, semiconductors, medical/healthcare device, automotive, precision die/mold. We also collaborate with world-leading manufacturers in semiconductor fabrication.

Welcome to HIT video for more application of ultrasonic technology.