1. Ultrasonic high-speed frequency vibration with 20,000-32,000 times per second

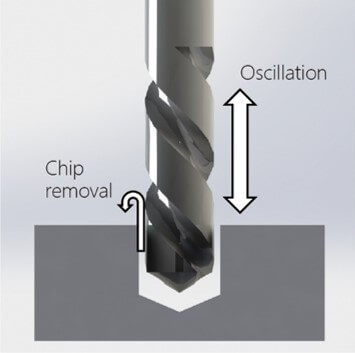

The machining technology of HIT ultrasonic machining module is mainly used to provide cutting tools in a fixed direction (Z-axis direction only) at a high-frequency of over 20,000 times per second oscillation. The ultrasonic amplitude allows for higher machining efficiency due to more efficienct material removal. By reducing the cutting force, there will be longer tool life and much less chipping of hard-to-cut materials, which eventually brought better workpiece quality.

2. Non-contact power transmission ultrasonic processing technology

Since the ultrasonic toolholder contains key electronic components, the ultrasonic power transmission represents an essential part within the technology. HIT ultrasonic machining module utilizes the non-contact power transmission technology to transmit the ultrasonic power on to the cutting toola. A patented precision actuation mechanism is embedded inside the toolholder, which generates high-frequency micro-vibration on the cutting tool.

3. Automatic identification & tracking control function

With the integration of automatic identification and tracking control function, HIT ultrasonic products can be widely applied to various industries. HIT also established a field application team which specializes in providing professional guide for customers in terms of ultrasonic-assisted machining advanced materials.

By providing a more flexible working space and an intelligent solution to the entire machining process, HIT offers customers an opportunity to achieve a more efficient and stable production.

Contact us for complete ultrasonic machining solution.

What’s the specialties of HIT Ultrasonic Machining Module?

Application cases validated with HIT Ultrasonic Machining Module