*The ultrasonic grinding wheel toolholder module includes: an ultrasonic driver, an ultrasonic grinding wheel toolholder, a power transmitter, and an external control box.

HBT-40-W01 / HSK-A63-W01 Ultrasonic Grinding Wheel Machining Module: Solution to Advanced Material Processing

1. The non-contact/wireless power transmission system allows high rotation speeds, suitable for high-precision advanced-material machining.

2. Modular design provides convenience and flexibility during installation.

3. Ultrasonic high-frequency vibration delivers high-efficiency and high-quality machining performance.

4. Ultrasonic vibration reduces grinding force, effectively extending wheel life.

5. Intelligent automatic frequency-tracking system is developed for advanced materials.

HBT-40-W01 / HSK-A63-W01 Ultrasonic Grinding Wheel Toolholder: Product Specification

| Model |

HBT-40-W01 / HSK-A63-W01 |

| Balance Quality Grade |

G2.5 |

| Operating Frequency |

20 ~ 34 kHz |

| Max. Rotation Speed |

10,000 RPM |

| Locking Mechanism |

Thread-locking |

| Weight |

2.2 kg |

| Automatic Tool Change (ATC) |

YES |

| Coolant Through Spindle (CTS) |

70 bar |

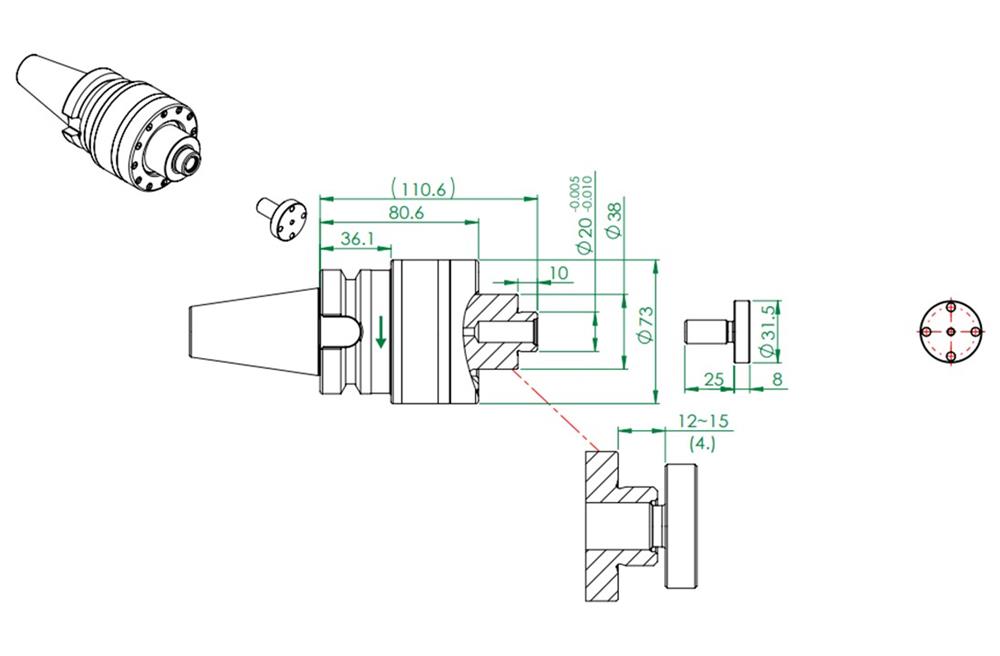

HBT-40-W01-2010 Ultrasonic Grinding Wheel Toolholder: Product Drawing & Dimensions

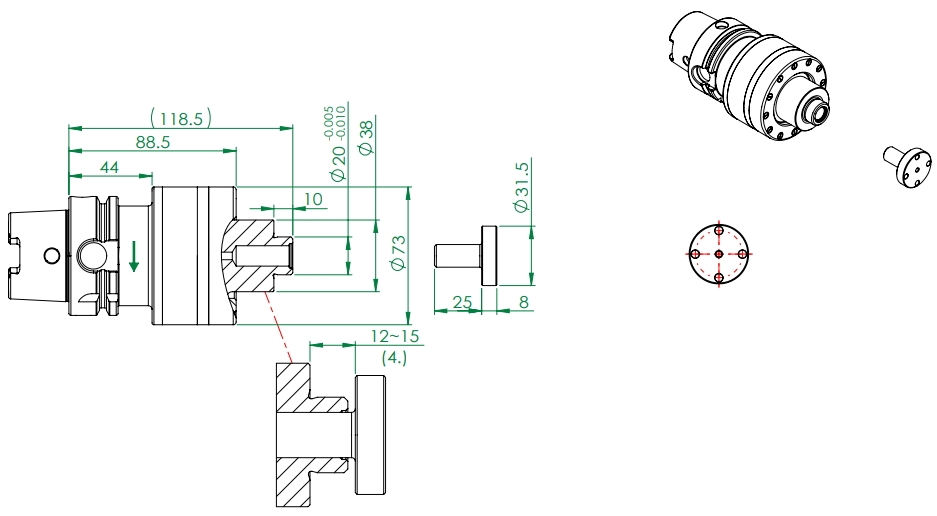

HSK-A63-W01-2010 Ultrasonic Grinding Wheel Toolholder: Product Drawing & Dimensions

【Grinding Wheel Selection】

💡It is recommended to purchase grinding wheels from HIT to ensure optimal ultrasonic performance and vibration mode consistency.

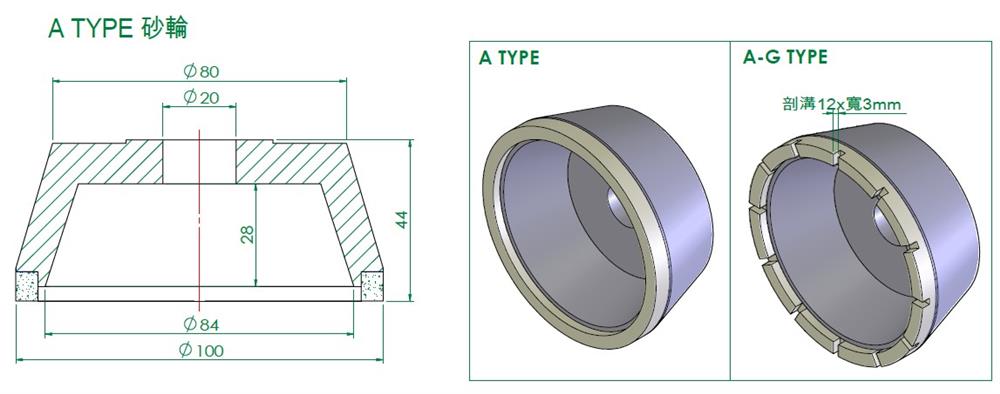

A Type Grinding Wheel

A Type Grinding Wheel

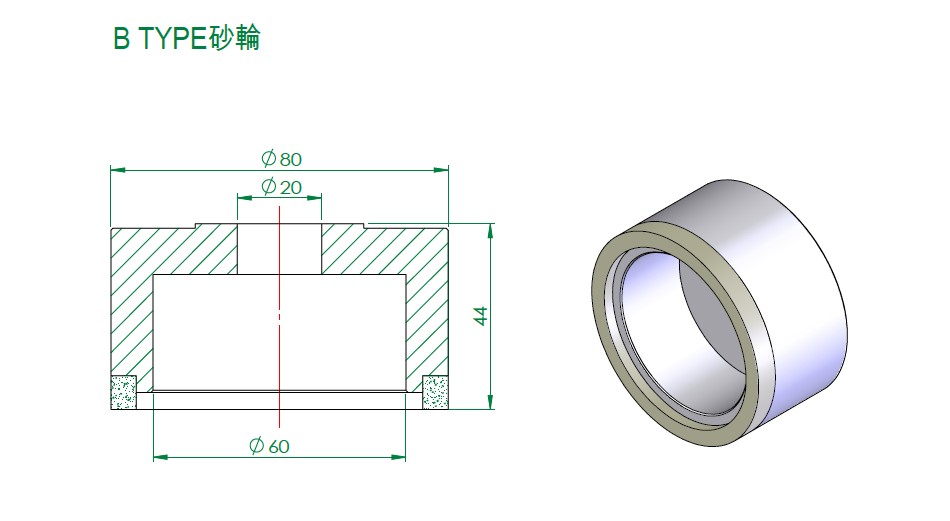

B Type Grinding Wheel

B Type Grinding Wheel

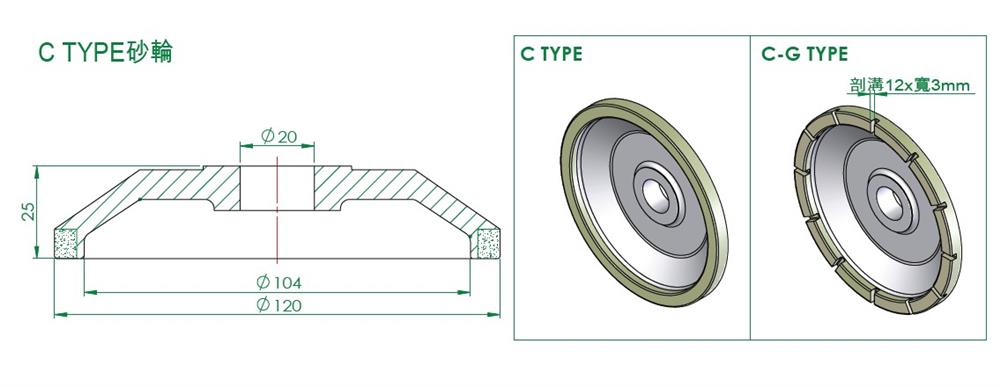

C Type Grinding Wheel

C Type Grinding Wheel

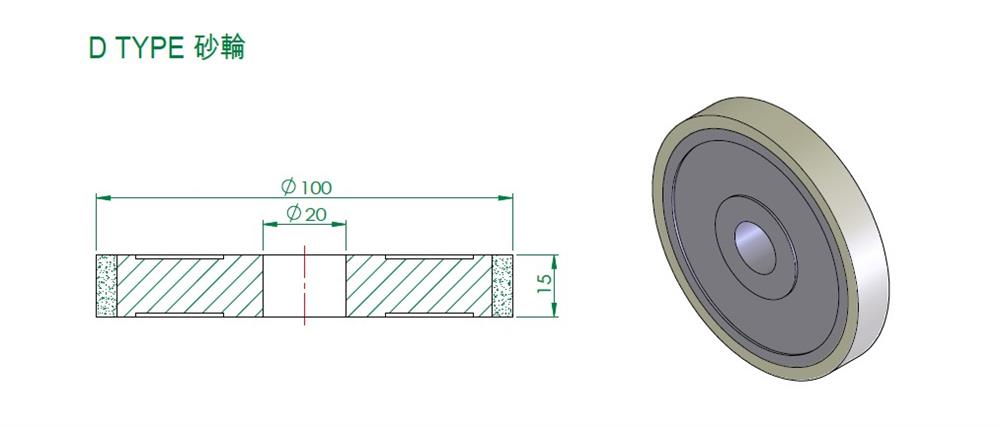

D Type Grinding Wheel

D Type Grinding Wheel

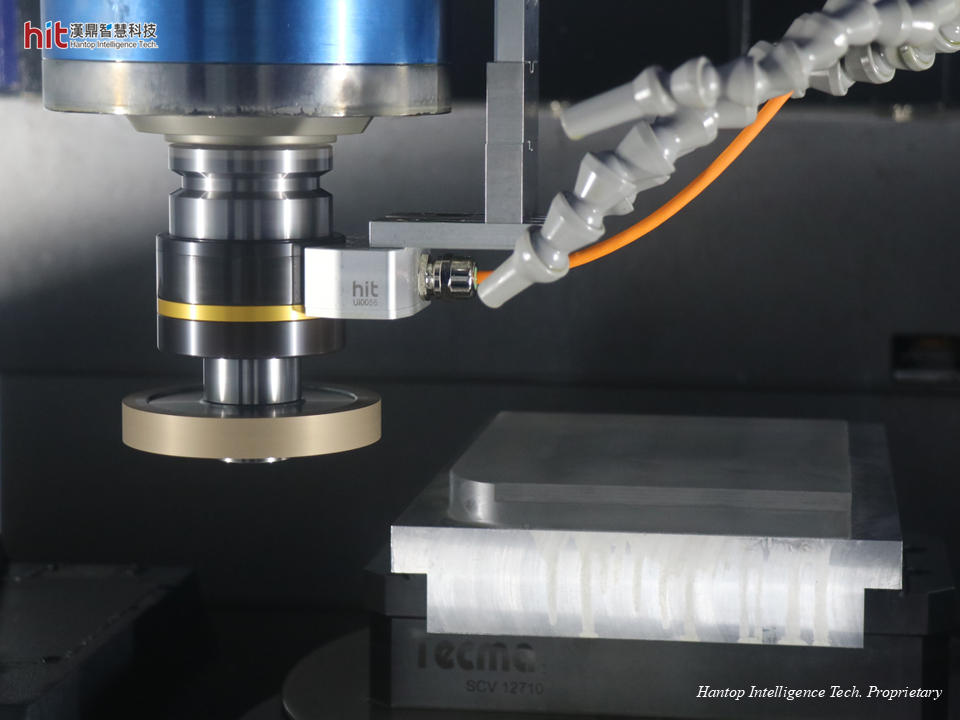

👉🏻 Preview of Ultrasonic Grinding Wheel Toolholder Application Cases:

---- As the Secret Weapon to March in the Supply Chain of Semiconductor Industry ----

🔹 Best applied in the rough grinding of semiconductor advanced-material

🔹 Overall Machining Efficiency: 2 - 3x Higher

🔹 Material Removal Rate (MRR): More than 3x Higher

🔹 Great reduction in production costs and energy consumption

【HBT-40 Ultrasonic Grinding Wheel Toolholder】Benefits Analysis from the Preliminary Tests

(Figure 1. HIT HBT-40 Ultrasonic Grinding Wheel Toolholder was used on side grinding of quartz glass)

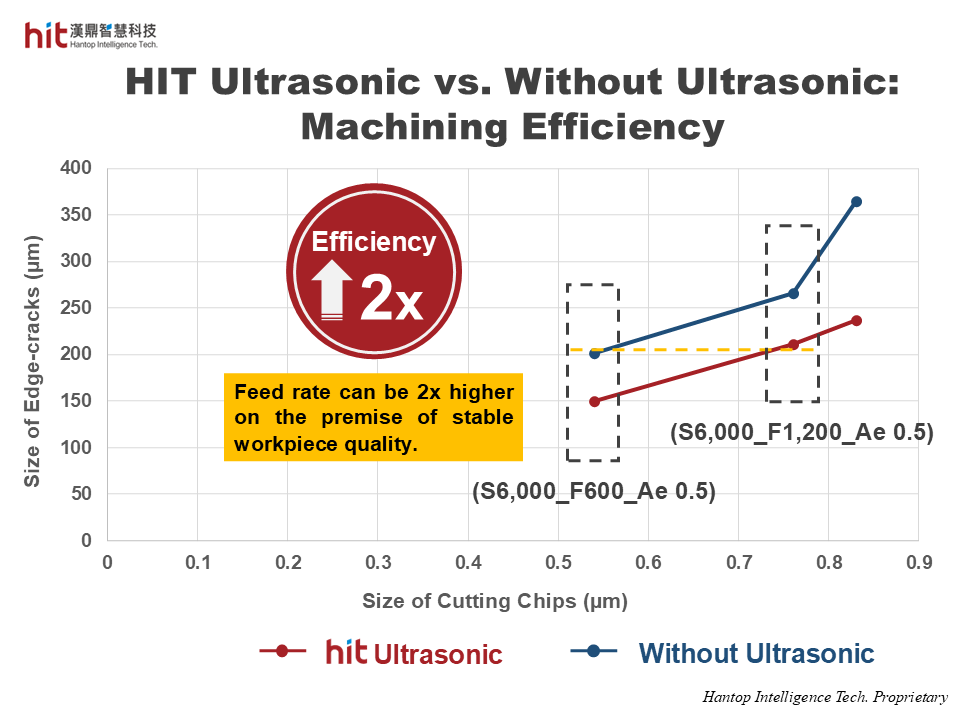

Ultrasonic-assisted Side Grinding of Quartz Glass: Machining Efficiency

(Figure 2. With HIT HBT-40 Ultrasonic Grinding Wheel Toolholder, feed rate can be 2x higher on the premise of stable workpiece quality, which brought 2x higher overall machining efficiency)

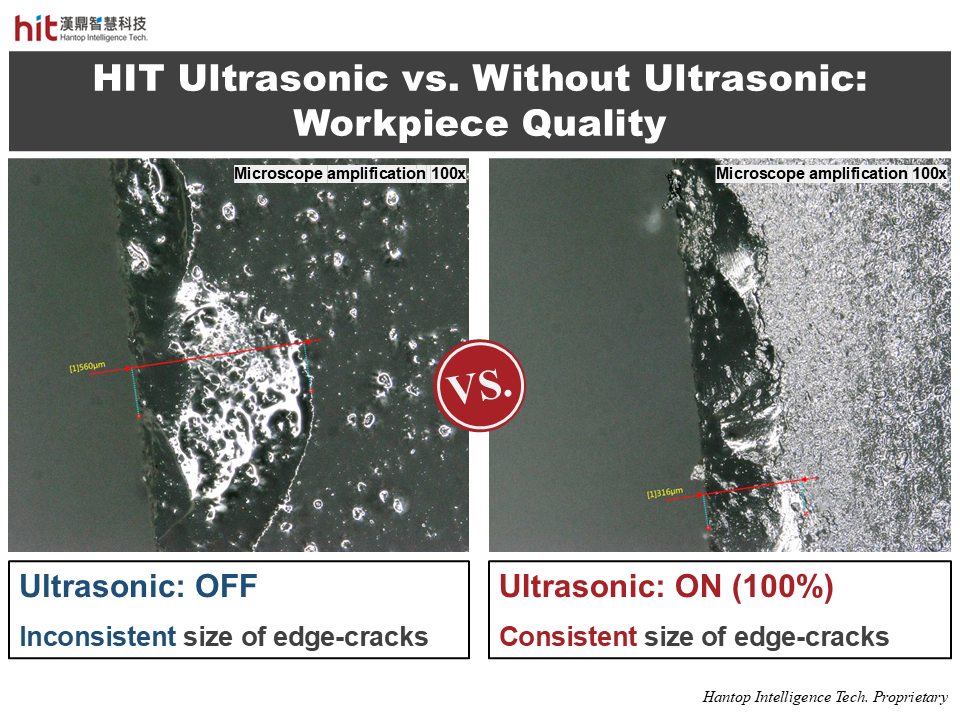

Ultrasonic-assisted Side Grinding of Quartz Glass: Workpiece Quality

(Figure 3. With HIT HBT-40 Ultrasonic Grinding Wheel Toolholder, size of edge-cracks was consistent compared to that without ultrasonic under 2x higher efficiency)

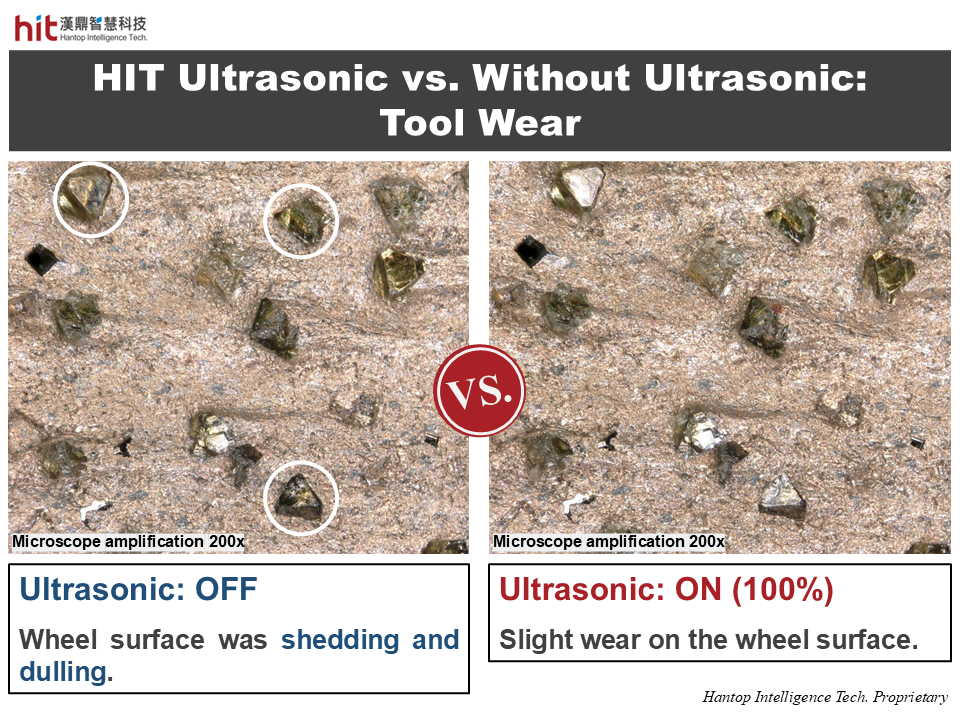

Ultrasonic-assisted Side Grinding of Quartz Glass: Tool Wear

(Figure 4. With HIT HBT-40 Ultrasonic Grinding Wheel Toolholder, wheel surface only had slight wear compared to that without ultrasonic under 2x higher efficiency)

To improve the machining efficiency, workpiece quality, and tool life, by following the trend of ESG, feel free to CONTACT US.

-

Hantop Intelligence Tech.

✨Solution Provider of Advanced-Material Machining Technology & Smart Automation Modules✨

☎️ +886-4-2285-0838

📧 sales@hit-tw.com