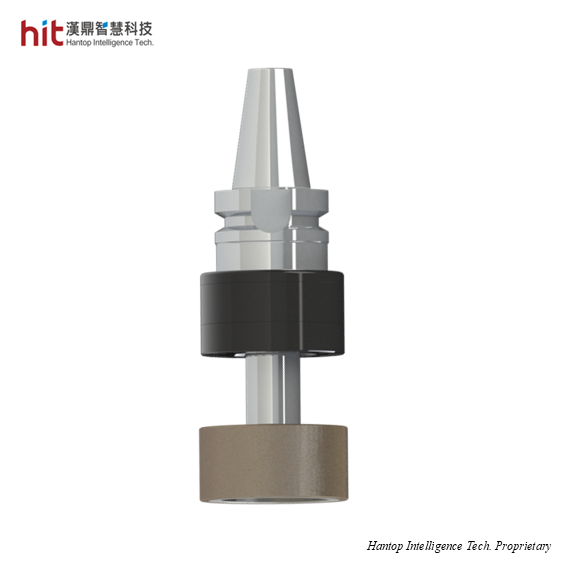

*The ultrasonic grinding wheel toolholder module includes: an ultrasonic driver, an ultrasonic grinding wheel toolholder, a power transmitter, and an external control box.

HBT-30-W02 / HSK-E40-W02 Ultrasonic Grinding Wheel Machining Module: Solution to Advanced Material Processing

1. The non-contact/wireless power transmission system allows high rotation speeds, suitable for high-precision advanced-material machining.

2. Modular design provides convenience and flexibility during installation.

3. Ultrasonic high-frequency vibration delivers high-efficiency and high-quality machining performance.

4. Ultrasonic vibration reduces grinding force, effectively extending wheel life.

5. Intelligent automatic frequency-tracking system is developed for advanced materials.

HBT-30-W02 / HSK-E40-W02 Ultrasonic Grinding Wheel Toolholder: Product Specification

| Model |

HBT-30-W02 / HSK-E40-W02 |

| Balance Quality Grade |

G2.5 |

| Operating Frequency |

20 ~ 32 kHz |

| Max. Rotation Speed |

12,000 RPM |

| Locking Mechanism |

Thread-locking |

| Weight |

< 1 kg |

| Automatic Tool Change (ATC) |

YES |

| Coolant Through Spindle (CTS) |

70 bar |

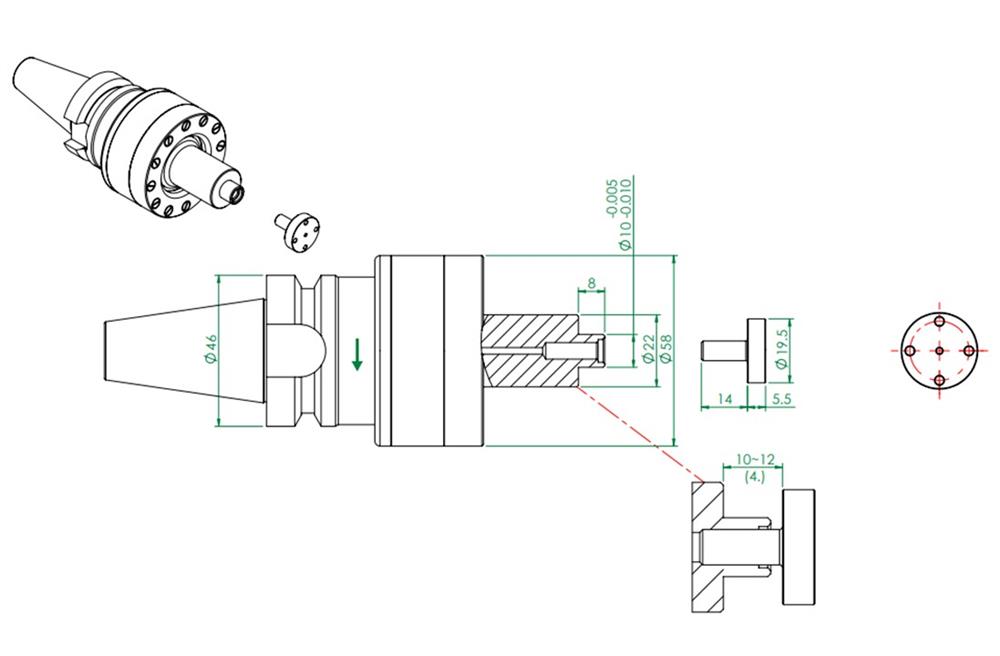

HBT-30-W02-1008 Ultrasonic Grinding Wheel Toolholder: Product Drawing & Dimensions

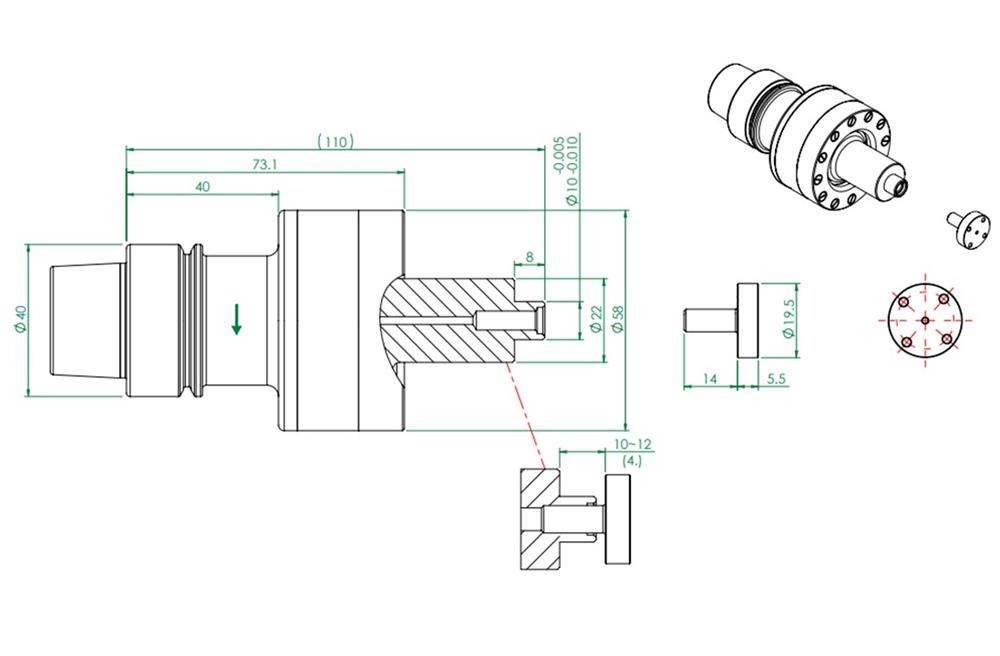

HSK-E40-W02-1008 Ultrasonic Grinding Wheel Toolholder: Product Drawing & Dimensions

【Grinding Wheel Selection】

💡It is recommended to purchase grinding wheels from HIT to ensure optimal ultrasonic performance and vibration mode consistency.

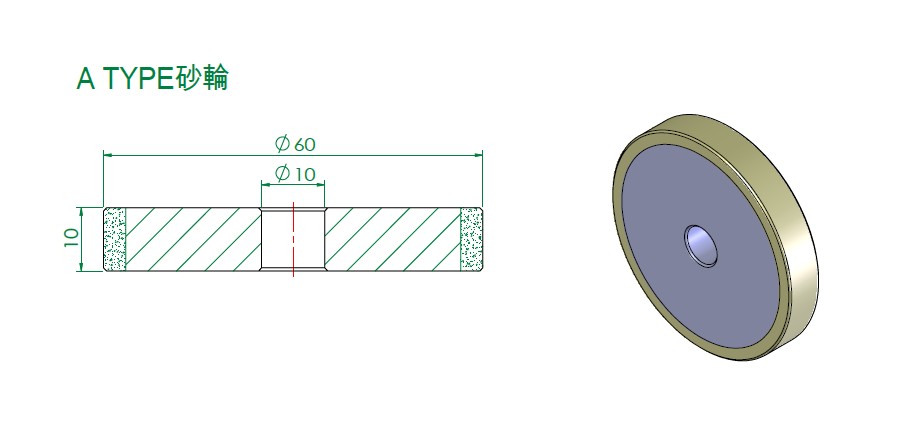

A Type Grinding Wheel

A Type Grinding Wheel

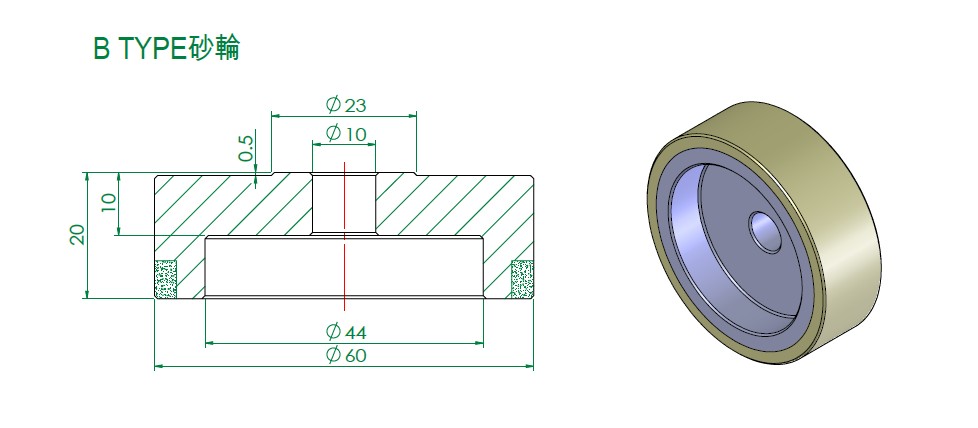

B Type Grinding Wheel

B Type Grinding Wheel

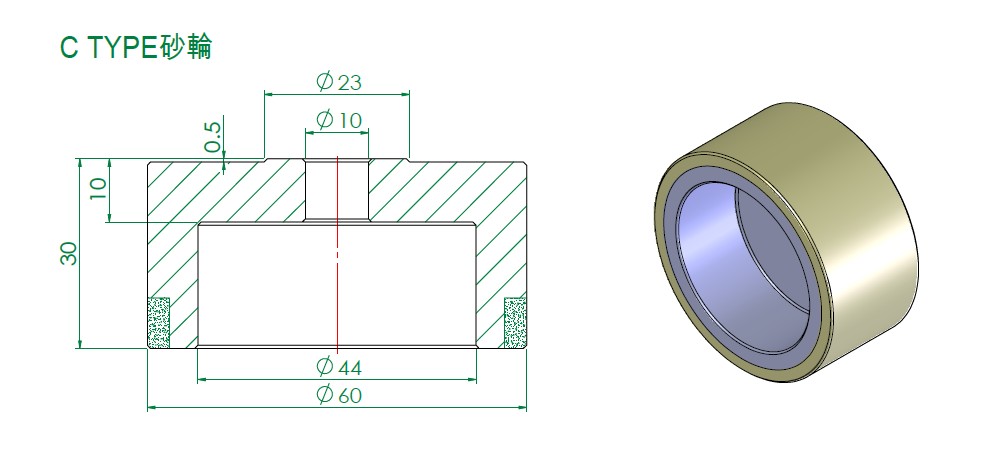

C Type Grinding Wheel

C Type Grinding Wheel

👉🏻 Preview of Ultrasonic Grinding Wheel Toolholder Application Cases:

To improve the machining efficiency, workpiece quality, and tool life, by following the trend of ESG, feel free to CONTACT US.

-

Hantop Intelligence Tech.

✨Solution Provider of Advanced-Material Machining Technology & Smart Automation Modules✨

☎️ +886-4-2285-0838

📧 sales@hit-tw.com