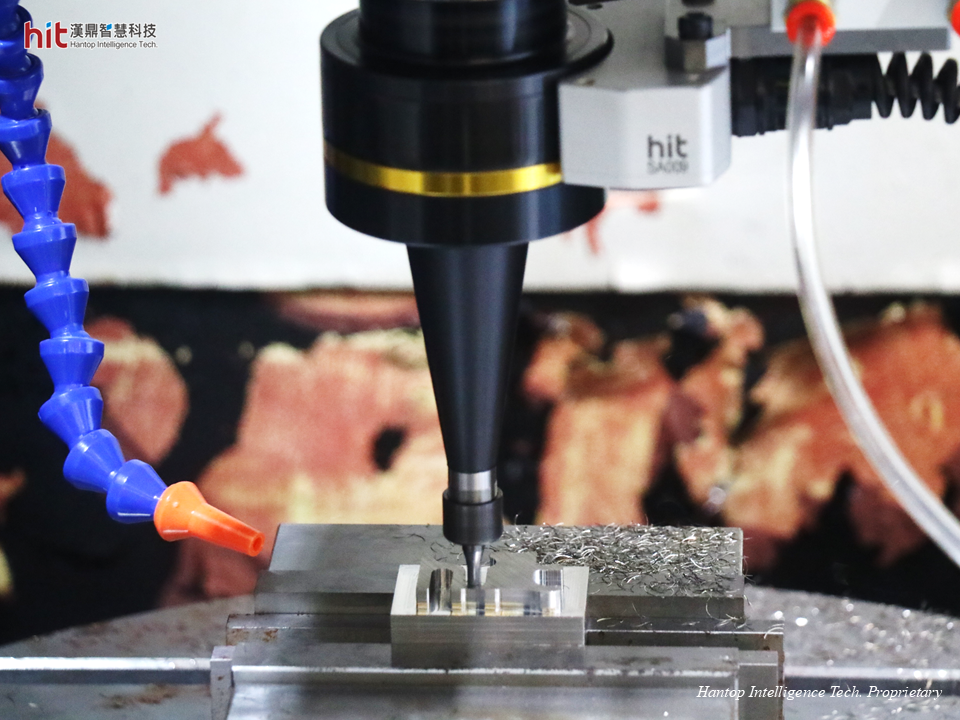

(Figure 1. HIT HSKA63-R30 ultrasonic machining module was used on profile milling - roughing of STAVAX mould steel)

HIT's Goal in Profile Milling (Roughing) of STAVAX Mould Steel

The goal is to enhance machining efficiency and reduce tool wear while maintaining great workpiece quality under low rotation speed with HIT HSKA63-R30 ultrasonic machining module.

Ultrasonic-Assisted Profile Milling (Roughing) of STAVAX Mould Steel: Machining Results

Profile Milling (Roughing) of STAVAX Mould Steel: Machining Efficiency

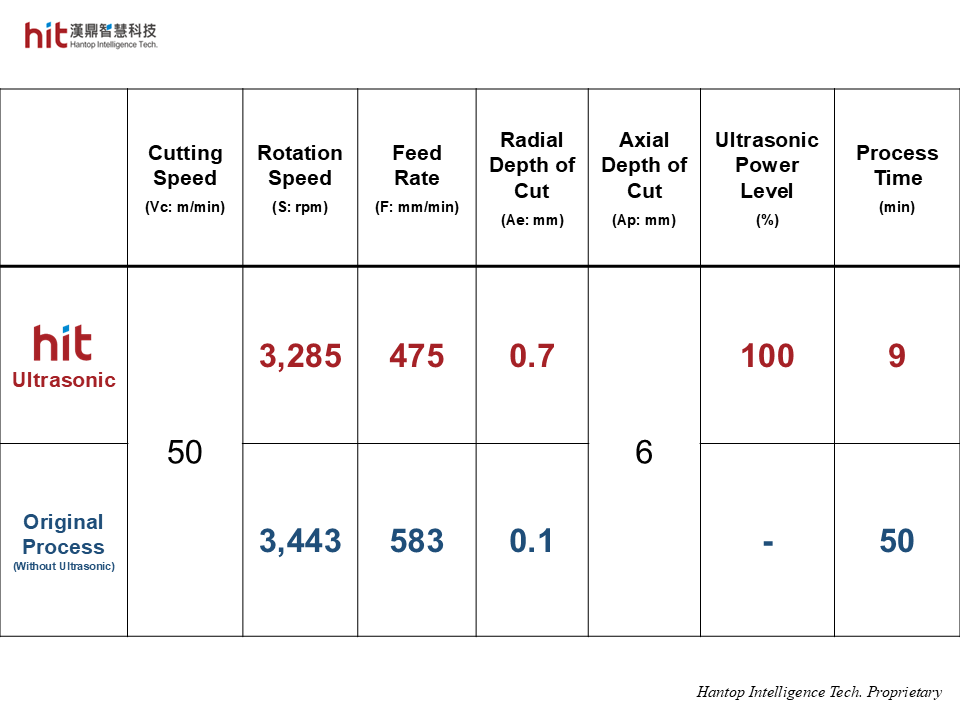

(Figure 2. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, total process time can be reduced by increasing radial depth of cut under low rotation speed compared to the original process)

- To optimize the profile milling (roughing) process of STAVAX mould steel with HIT ultrasonic, the high frequency micro-vibration helped reduce cutting force and cutting heat under low rotation speed.

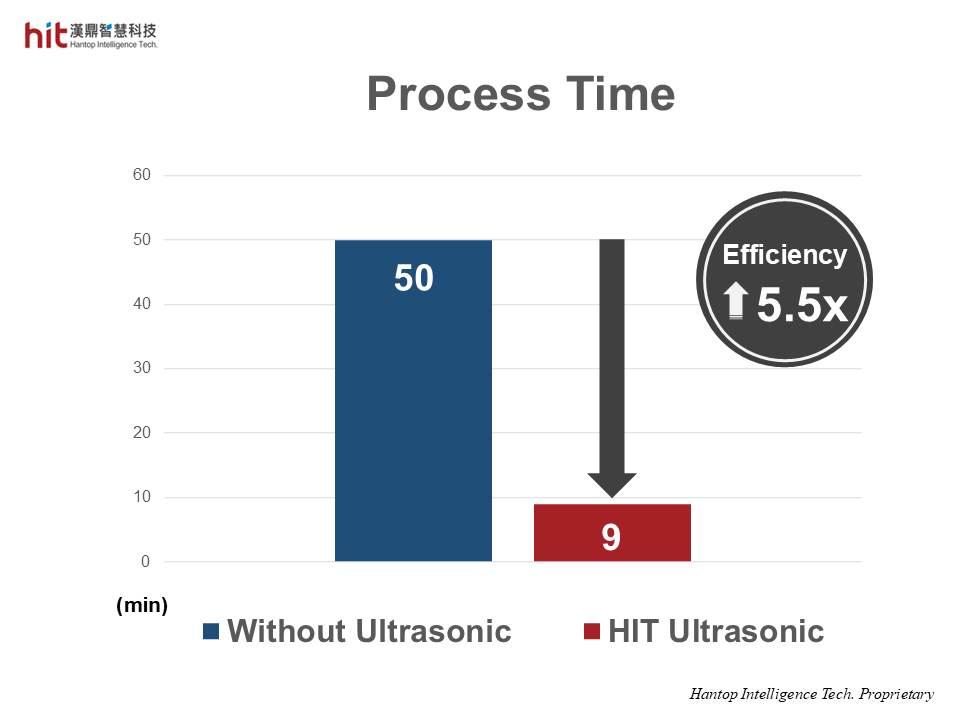

- The radial depth of cut (Ae) can be enhanced compared to the original process. This effectively shortened the total process time (from 50 minutes to 9 minutes in completing one workpiece), bringing a 5.5x higher machining efficiency.

(Figure 3. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, machining efficiency can be 5.5x higher compared to the original process)

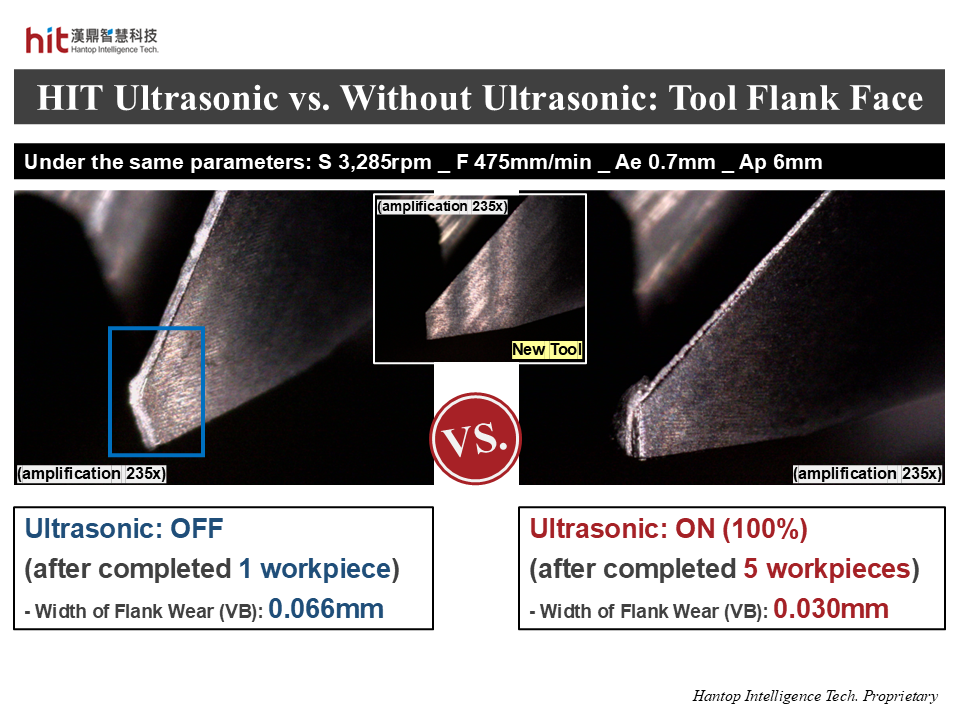

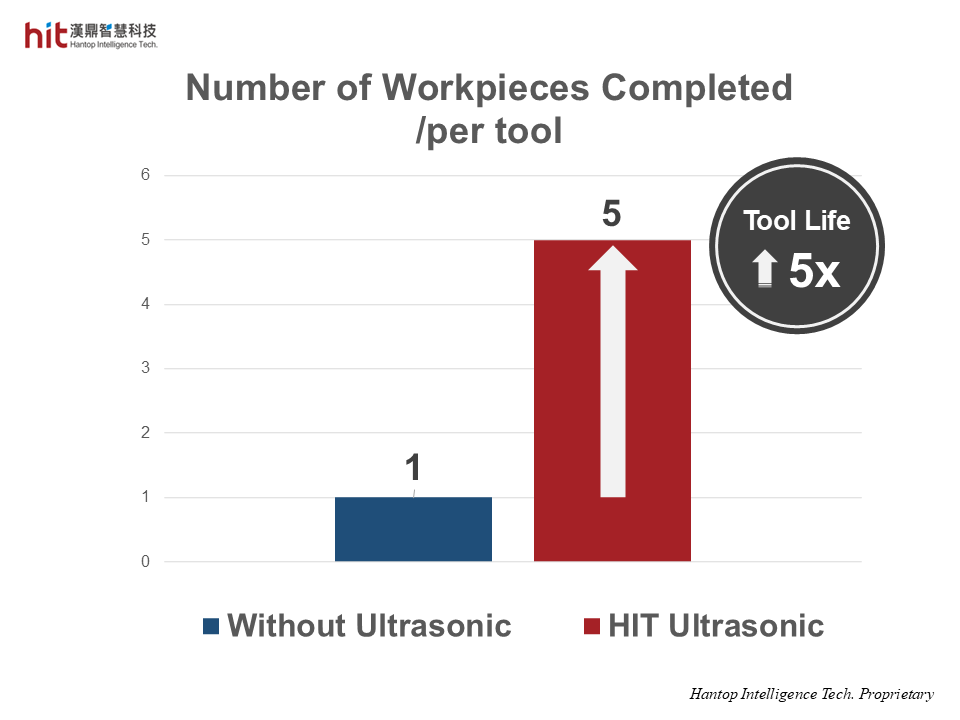

Profile Milling (Roughing) of STAVAX Mould Steel: Tool Life

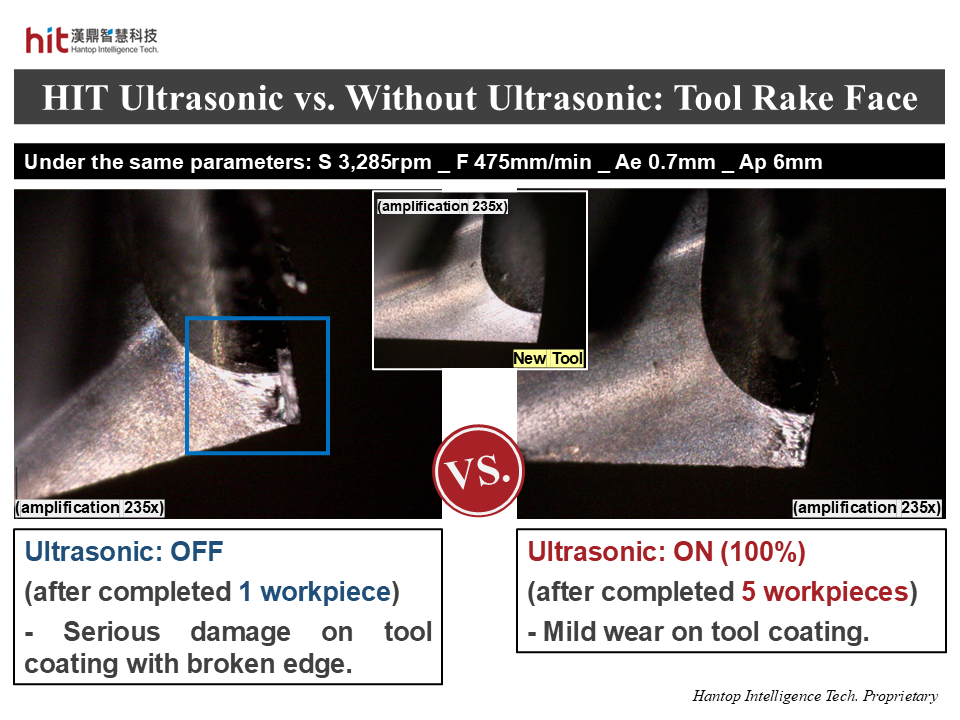

(Figure 4. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, cutting tool only had mild wear after completed 5 workpieces by using optimized parameters)

(Figure 5. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, the width of flank wear was much smaller than that without ultrasonic after completed 5 workpieces by using optimized parameters)

- To optimize the profile milling (roughing) process of STAVAX mould steel with HIT ultrasonic, it helped reduce cutting force/heat under low rotation speed, bringing a 5x longer tool life.

- Under the same (optimized) parameters, 5 workpieces can be completed per tool with ultrasonic. The tool only had mild wear with much smaller width of flank wear (VB). Whereas the tool can only complete 1 workpiece without ultrasonic, and it had serious wear with massive built-up edge (BUE) and breakage on the edge.

(Figure 6. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, tool life can be 5x longer by using optimized parameters)

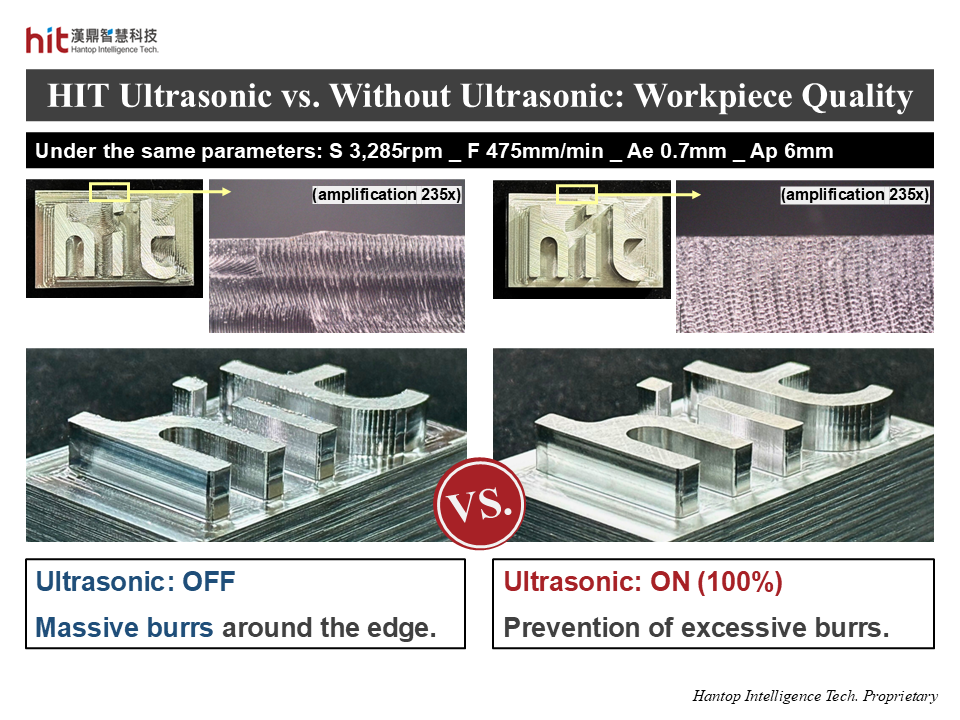

Profile Milling (Roughing) of STAVAX Mould Steel: Workpiece Quality

(Figure 7. with HIT HSKA63-R30 ultrasonic machining module in profile milling - roughing of STAVAX mould steel, it effectively prevented excessive burrs around the edge workpiece by using optimized parameters)

- To optimize the profile milling (roughing) process of STAVAX mould steel with HIT ultrasonic, the reduction in cutting force/heat brought an increase in machining efficiency and a decrease in tool wear.

- Due to serious wear on the edge of tool blade without ultrasonic, the increase of cutting force caused plastic deformation in the material, which generated massive burrs around the edge of workpiece.

HIT Ultrasonic Machining Technology Achievements in Profile Milling (Roughing) of STAVAX Mould Steel

🕜 Efficiency - 5.5x higher, reduced total process time

⚙️ Tool Life - 5x longer, reduced tool wear

📈 Workpiece Quality - Prevention of excessive burrs around workpiece