(Figure 1. HIT HSKA63-R30 ultrasonic machining module was used on side milling of STAVAX mould steel)

HIT's Goal in Side Milling of STAVAX Mould Steel

The goal is to improve tool wear while maintaining great workpiece quality under high cutting speed with HIT HSKA63-R30 ultrasonic machining module.

Ultrasonic-Assisted Side Milling of STAVAX Mould Steel: Machining Results

Side Milling of STAVAX Mould Steel: Chip Formation

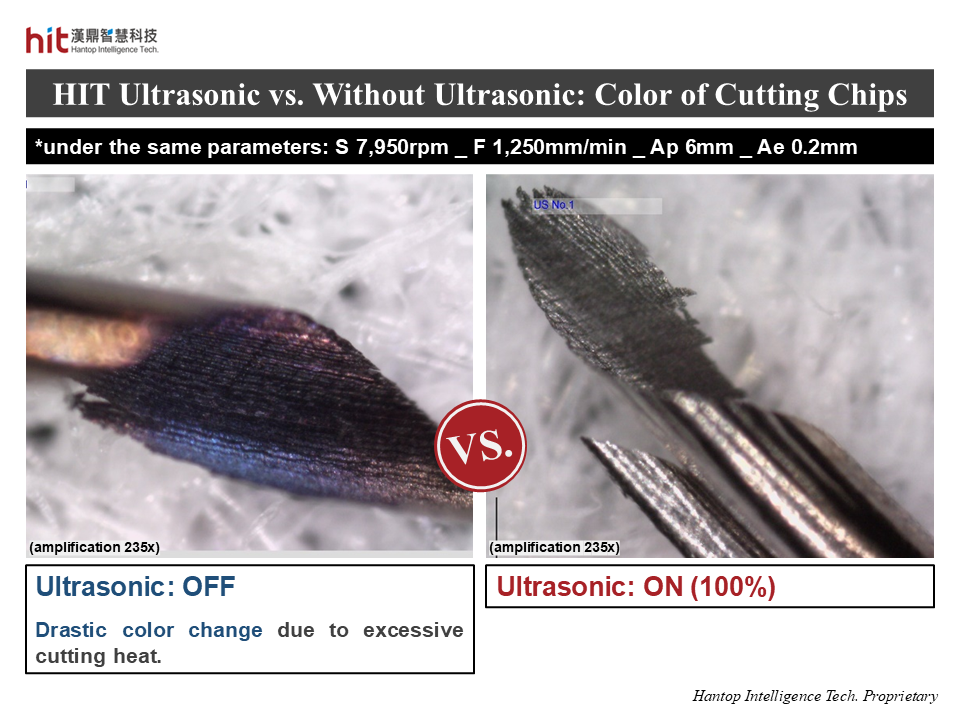

(Figure 2. with HIT HSKA63-R30 ultrasonic machining module in side milling of STAVAX mould steel, cutting heat can be effectively removed)

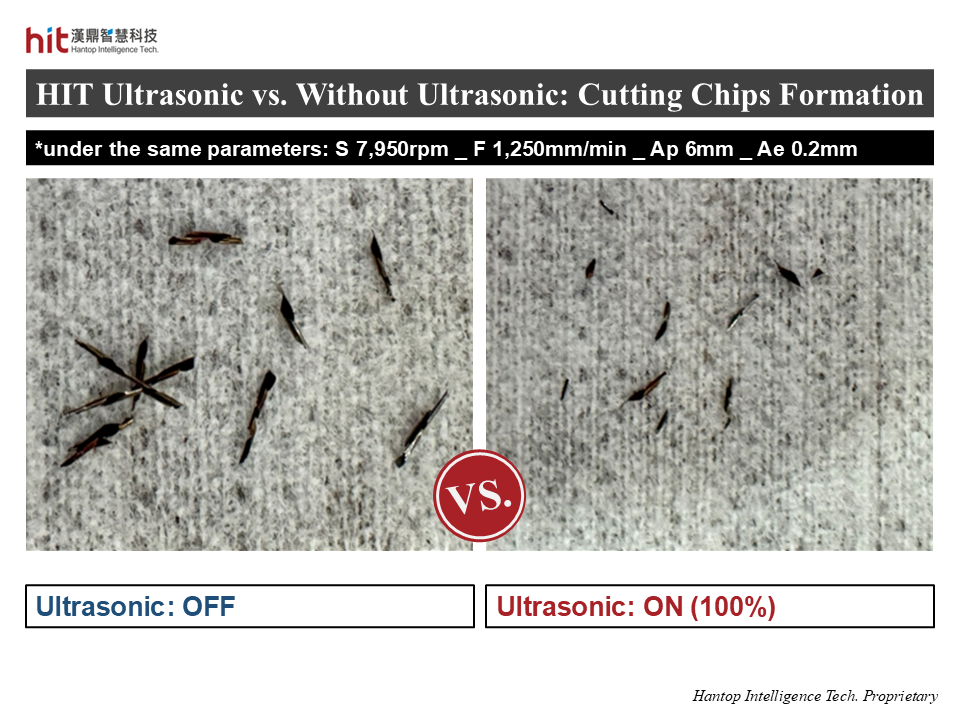

(Figure 3. with HIT HSKA63-R30 ultrasonic machining module in side milling of STAVAX mould steel, cutting chips became shorter and smaller)

- To optimize the side milling process of STAVAX mould steel with HIT ultrasonic module, the change in cutting mechanism helped reduce cutting heat.

- Cutting chips were easily cut off by ultrasonic due to poor material ductility and malleability.

- Under high cutting speed without ultrasonic, it generated high cutting heat, causing drastic color change in the cutting chips.

Side Milling of STAVAX Mould Steel: Tool Life

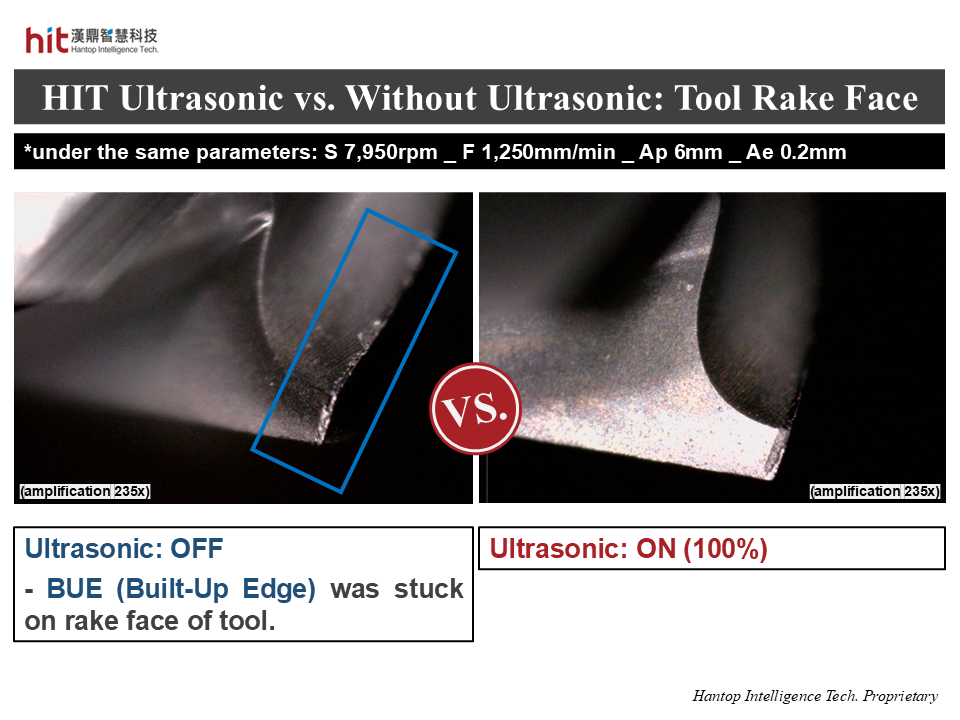

(Figure 4. with HIT HSKA63-R30 ultrasonic machining module in side milling of STAVAX mould steel, it helps reduce the occurrence of BUE)

- Using HIT ultrasonic module to optimize the side milling process of STAVAX mould steel, cutting chips were easily cut off and removed with the cutting mechanism of ultrasonic. This helped avoid BUE (Built-Up Edge) from getting stuck on the tool, reducing tool wear on the rake face.

- Under high cutting speed without ultrasonic, more BUE was stuck on the rake face due to excessive cutting heat.

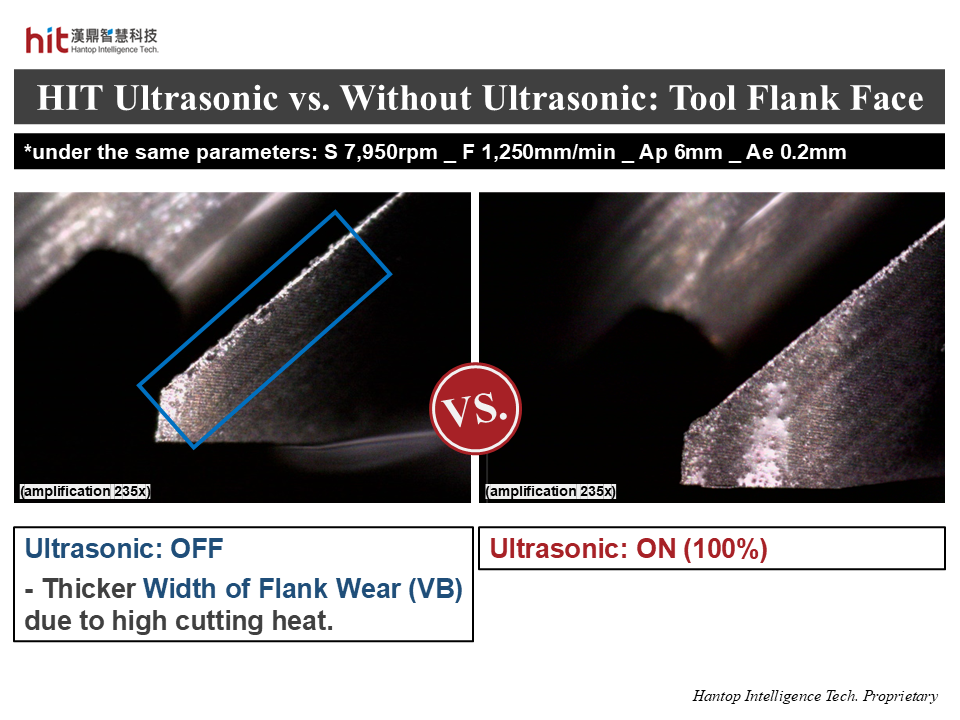

(Figure 5. with HIT HSKA63-R30 ultrasonic machining module in side milling of STAVAX mould steel, it helps reduce the width of flank wear)

- Using HIT ultrasonic module to optimize the side milling process of STAVAX mould steel, the high frequency micro-vibration helped remove cutting heat, which brought reduction in tool wear.

- Under high cutting speed without ultrasonic, the high cutting heat and cutting chips increased the cutting force. This caused serious tool wear with thicker width of flank wear (VB).

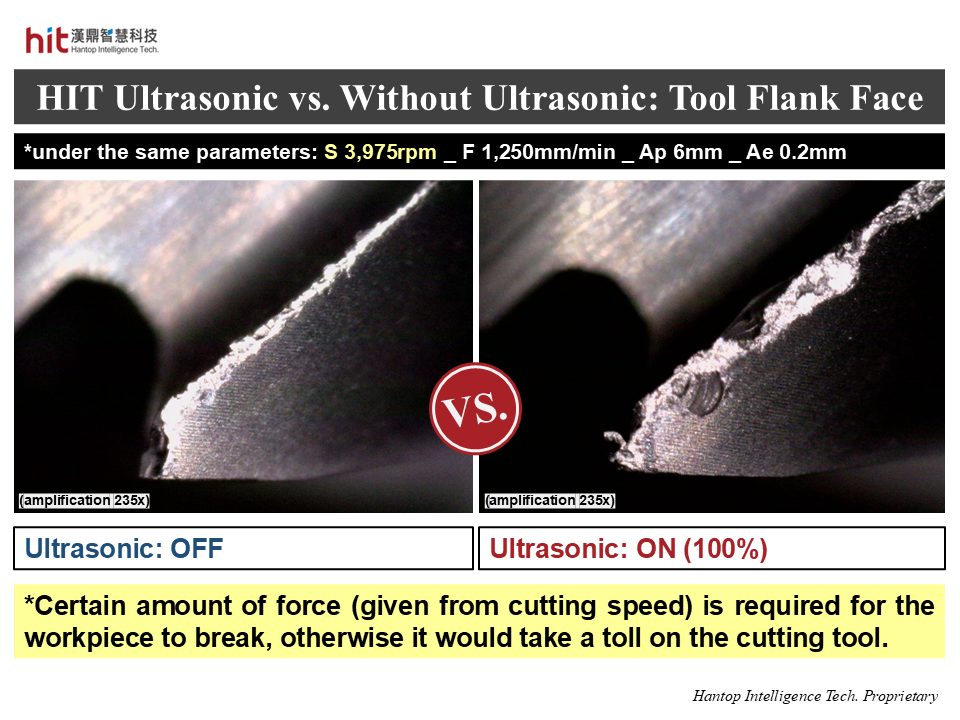

(Figure 6. with HIT HSKA63-R30 ultrasonic machining module in side milling of STAVAX mould steel, low cutting speed would increase cutting force instead, causing serious tool wear)

- Certain amount of force (given from cutting speed) is required for the workpiece to break, while dealing with hardened steel materials such as STAVAX.

- Based on the tool condition with and without ultrasonic, low cutting speed (3,975rpm, and the optimized parameter is 7,950rpm) is not recommended for this process.

HIT Ultrasonic Machining Technology Achievements in Side Milling of STAVAX Mould Steel

📈 Cutting Chip Formation - effectively remove cutting heat, and cutting chips can be easily cut off by ultrasonic

⚙️ Tool Life - greatly reduced tool wear and the occurrence of BUE