(Figure 1. HIT HBT-40 ultrasonic machining module was used on AISI-4140 alloy steel full slotting)

HIT's Goal in AISI-4140 Alloy Steel Full Slotting

The goal is to enhance the surface quality of slot wall while maintaining high efficiency, and prolong the tool life.

Ultrasonic-Assisted AISI-4140 Alloy Steel Full Slotting: Machining Results

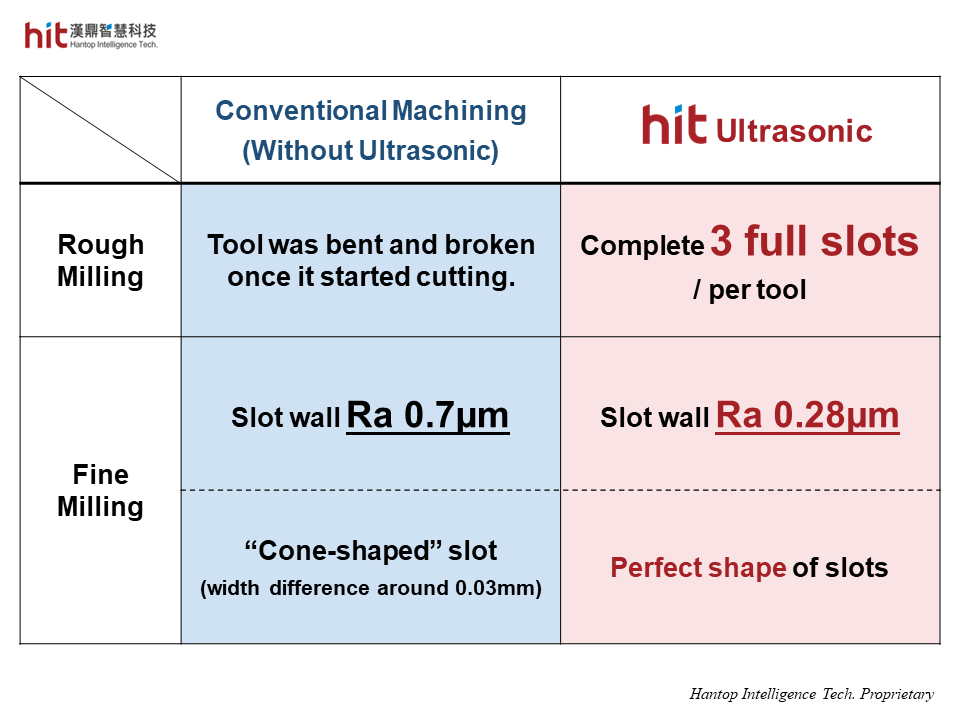

(Figure 2. the comparison of machining results between HIT ultrasonic-assisted full slotting AISI-4140 alloy steel and without ultrasonic)

【AISI-4140 Alloy Steel Full Slotting: Rough Milling Process】

- In conventional machining (without ultrasonic) of such high aspect ratio (6.2x) full slotting, high cutting force caused the tool bent and broken once it started cutting.

- With HIT ultrasonic, the high frequency micro-vibration allowed for easier inflow of cutting fluid. This helped bring better cooling effect and better evacuation of cutting chips. It managed to complete 3 full slots with one tool owing to great reduction in cutting force.

【AISI-4140 Alloy Steel Full Slotting: Fine Milling Process】

- In conventional machining (without ultrasonic), the poor results from rough milling also imapcted the fine milling process. Awful surface roughness of slot wall (Ra 0.7µm) and "cone-shaped" slot failed to meet up with customer's requirement.

- With HIT ultrasonic, the fine milling process only took one tool to complete. The great reduction in cutting force helped improve 2.5x of surface roughness (Ra 0.28µm) with perfect shape of slots (width of the 3 full slots were all 0.73mm).

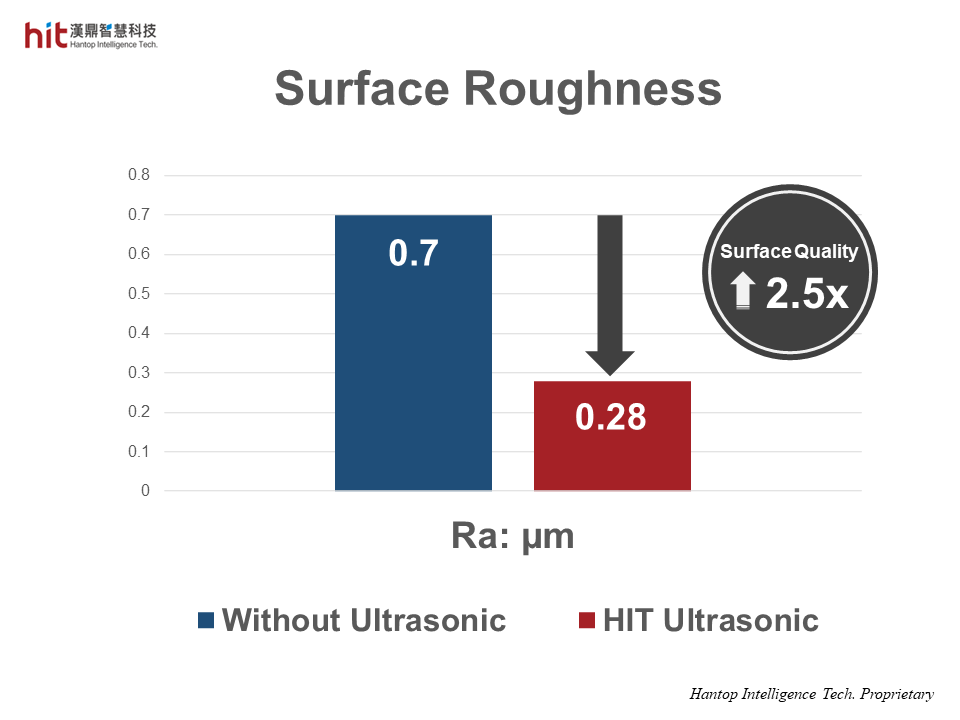

AISI-4140 Alloy Steel Full Slotting: Workpiece Quality

(Figure 3. HIT ultrasonic-assisted full slotting AISI-4140 alloy steel achieved 2.5x better surface quality)

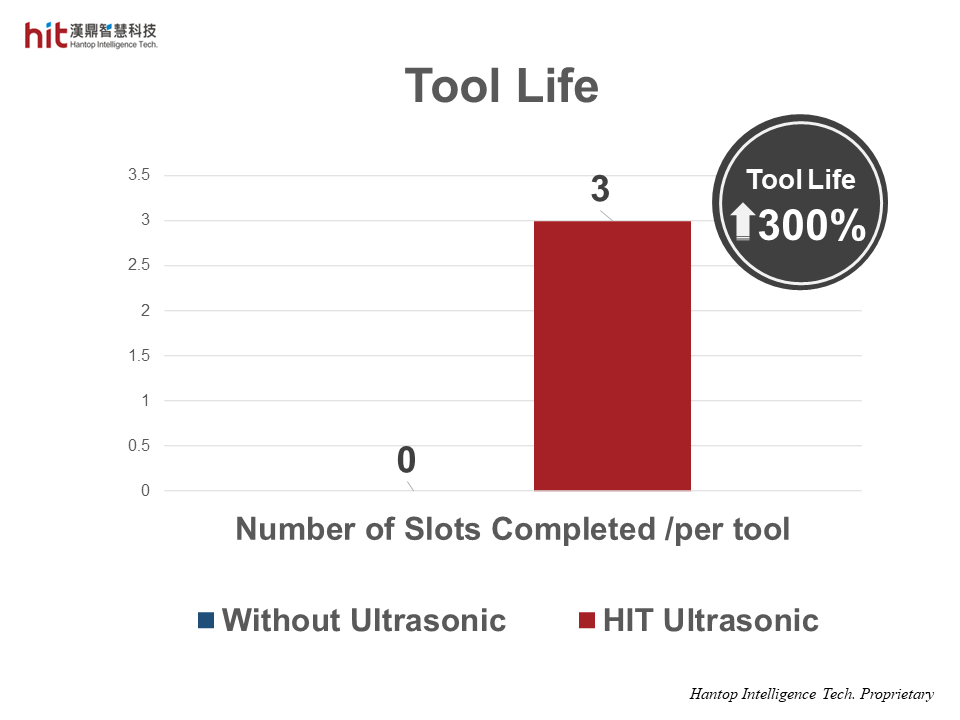

AISI-4140 Alloy Steel Full Slotting: Tool Life

(Figure 4. HIT ultrasonic-assisted full slotting AISI-4140 alloy steel achieved 300% longer tool life, from failing to cut, to cutting 3 full slots per tool)

HIT Ultrasonic Machining Technology Achievements

📈 Quality - surface roughness (Ra) improved 2.5x

⚙️ Tool Life - 300% longer (from failing to cut, to cutting 3 full slots per tool)