(Figure 1. HIT HSK-A63 ultrasonic machining module was used on circular pocket milling of nickel alloy Inconel 718)

HIT's Goal in Circular Pocket Milling of Nickel Alloy (Inconel 718)

The goal is to achieve higher machining efficiency and longer tool life on doing circular pocket milling of nickel alloy (Inconel 718) with HIT ultrasonic-assisted machining technology.

Ultrasonic-Assisted Circular Pocket Milling of Nickel Alloy (Inconel 718) Machining Results

Nickel Alloy (Inconel 718) Circular Pocket Milling: Machining Efficiency

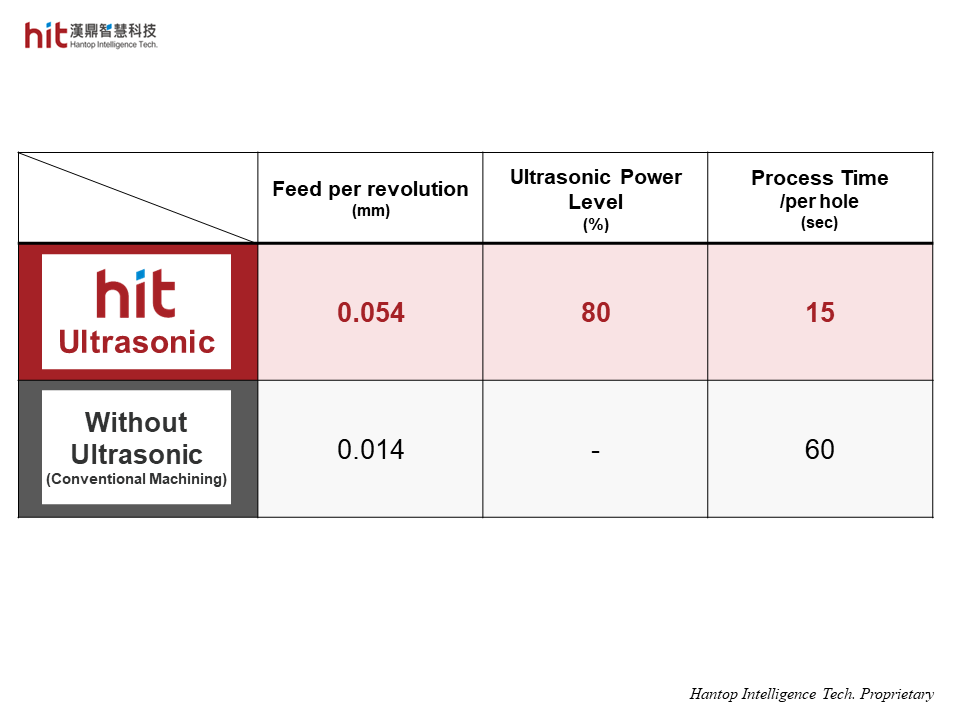

(Figure 2. Feed per revolution was enhanced 4x faster with HIT ultrasonic)

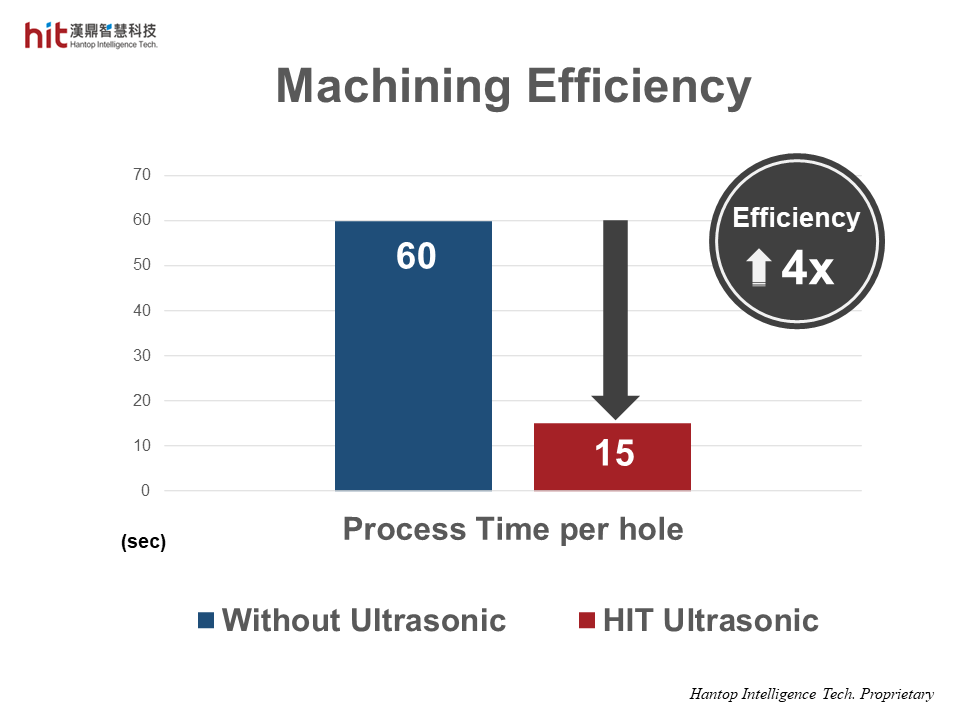

- With HIT ultrasonic, the high frequency micro-vibration allowed the tool to constantly lift from the workpiece. This brought better cooling effect and better chip evacuation, which helped reduce cutting force.

- The reduction in cutting force allowed for an increase in feed per revolution and achived 4x shorter process time (per hole).

- Since the bottom blade (end cutting edge) of tool did the cutting primarily during circular pocket milling, it could avoid the work-hardened layer on the material by increasing feed per revolution.

(Figure 3. HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718 achieved 4x higher machining efficiency)

Nickel Alloy (Inconel 718) Circular Pocket Milling: Tool Life

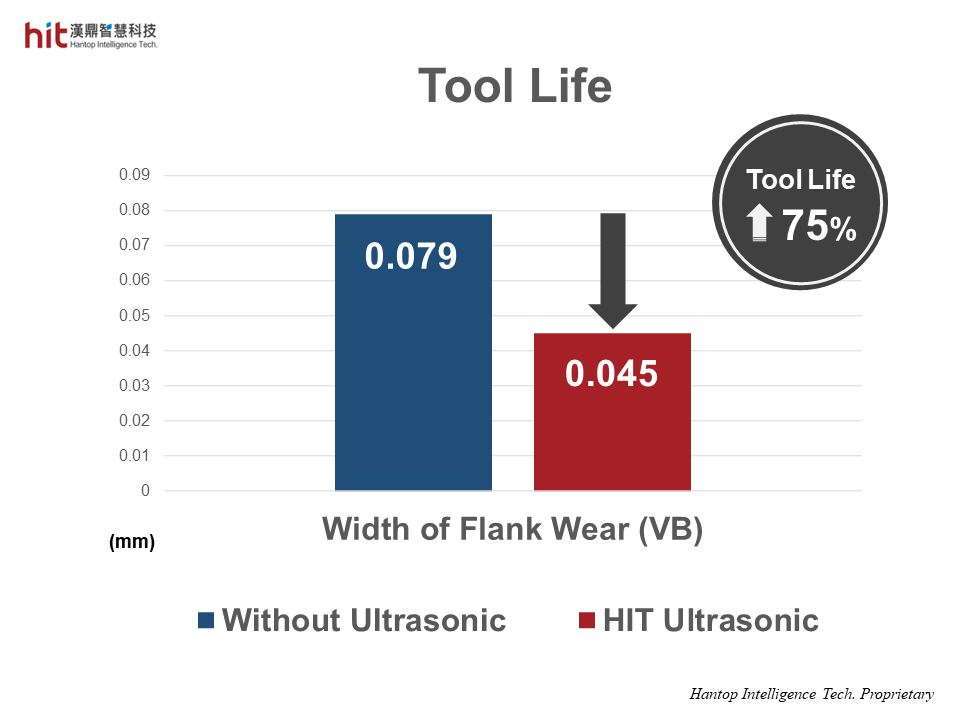

(Figure 4. Increase in feed per revolution in HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718 helped avoid cutting into the work-hardened layer of the material and reduced cutting force)

- With HIT ultrasonic, the better cooling effect and chip evacuation prevented the occurrence of BUE (Built-Up Edge). The increase in feed per revolution helped avoid tool from striking the work-hardened layer on the material. The reduction in cutting force and tool wear brought 75% longer tool life.

- The work-hardened chips were hard to evacuate due to excessive heat under continuous cutting in conventional machining. This caused massive BUE stuck on tool blade and increased the cutting force, which then resulted in poor tool life.

(Figure 5. HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718 achieved 75% longer tool life)

Nickel Alloy (Inconel 718) Circular Pocket Milling: Chip Formation

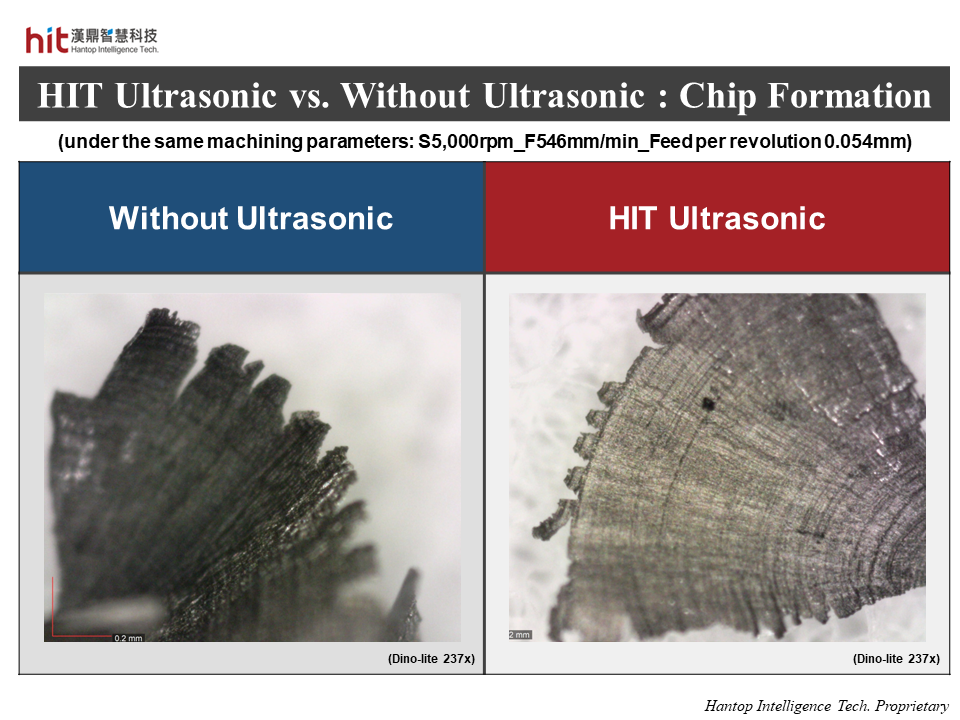

(Figure 6. Better cooling effect and chip evacuation changed the chip formation in HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718)

- With HIT ultrasonic, the better cooling effect and chip evacuation prevented the occurrence of BUE (Built-Up Edge). The increase in feed per revolution helped avoid tool from striking the work-hardened layer on the material, which brought the reduction in cutting force and tool wear.

- Chips appeared to be darker due to excessive heat under continuous cutting in conventional machining. Adiabatic shear failure* resulted in chips with jagged edge, which could easily damage cutting tool and workpiece quality.

*Adiabatic Shear Failure: The heat generated by material deformation at high strain rates cannot be diffused in time, leading to local thermal instability of the material and forming Adiabatic Shear Band (ASB).

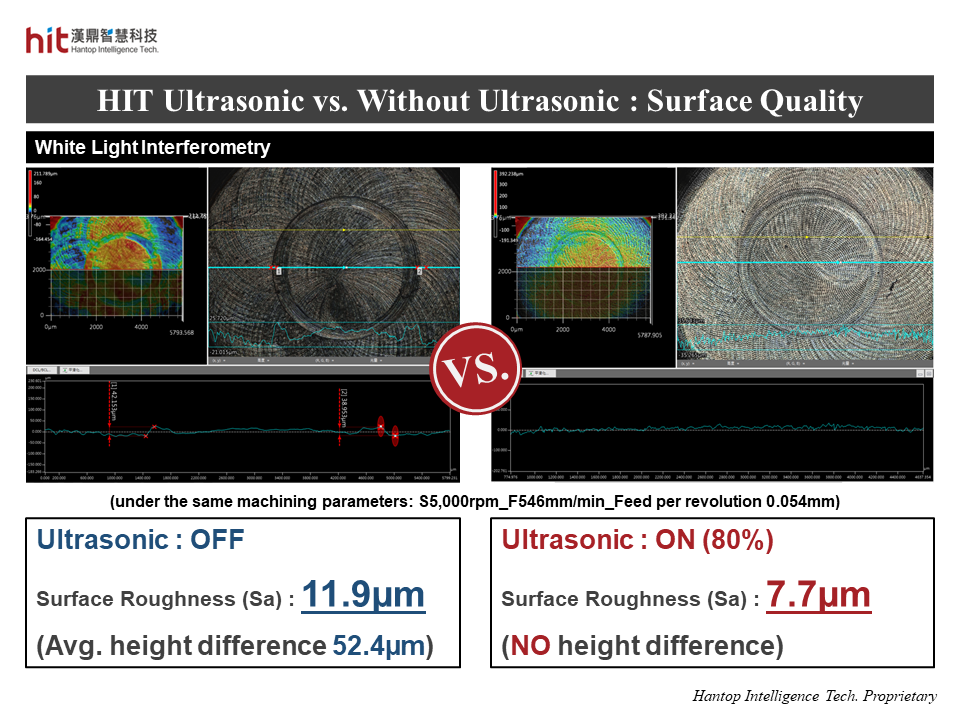

Nickel Alloy (Inconel 718) Circular Pocket Milling: Surface Quality

(Figure 7. HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718 helped reduce the surface roughness of workpiece with no height different on the surface)

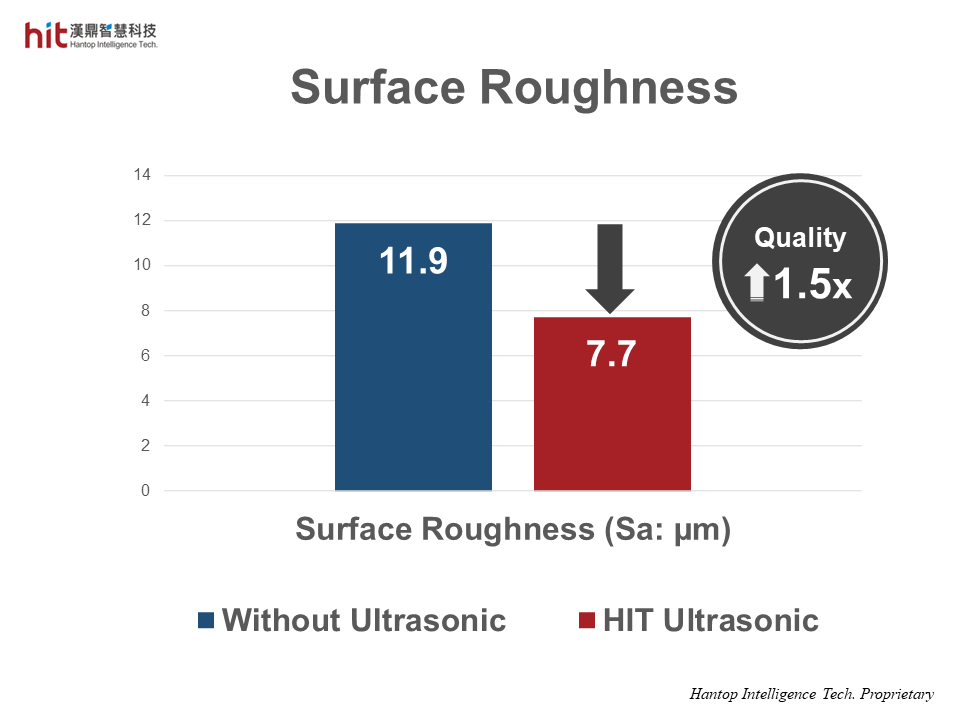

- With HIT ultrasonic, better cooling effect and chip evacuation prevented workpiece from re-cutting by the work-hardened BUE. Avoidance of cutting work-hardened layer reduced cutting force and achieved 1.5x higher surface quality.

- The excessive heat was hard to remove under continous cutting, resulting in darker color in the surface. The work-hardened chips stuck on tool blade (BUE), resulting in increasing cutting force. The poor surface quality and height difference in surface resulted from tool directly cutting into the work-hardened layer.

(Figure 8. HIT ultrasonic-assisted circular pocket milling of nickel alloy Inconel 718 achieved 1.5x better surface quality)

HIT Achievements in Circular Pocket Milling of Nickel Alloy (Inconel 718)

🕜 Efficiency - 4x higher

📈 Surface Quality - 1.5x better

⚙️ Tool Life - 75% longer