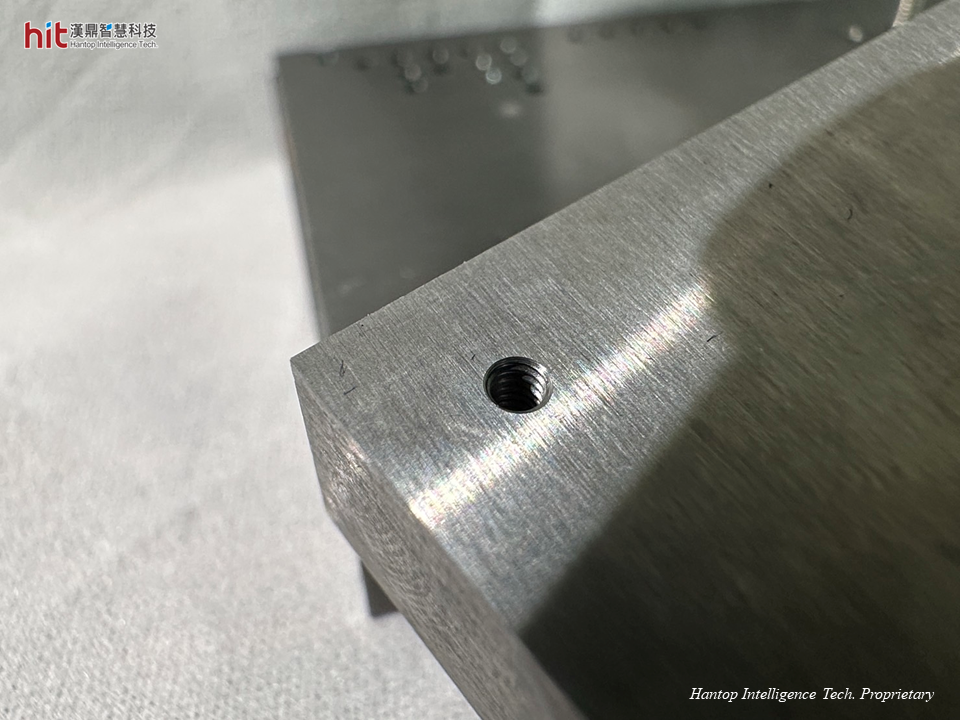

(Figure 1. HSK-E40 ultrasonic toolholder was used on the machining of tungsten carbide M2 internal threading)

(Figure 2. HIT ultrasonic-assisted machining of tungsten carbide M2 internal threading workpiece)

HIT's Goal in Machining Tungsten Carbide

The goal is to successfully make an M2 internal thread on tungsten carbide with HIT ultrasonic-assisted machining technology on CNC machine tool.

Ultrasonic-Assisted Machining Tungsten Carbide Results

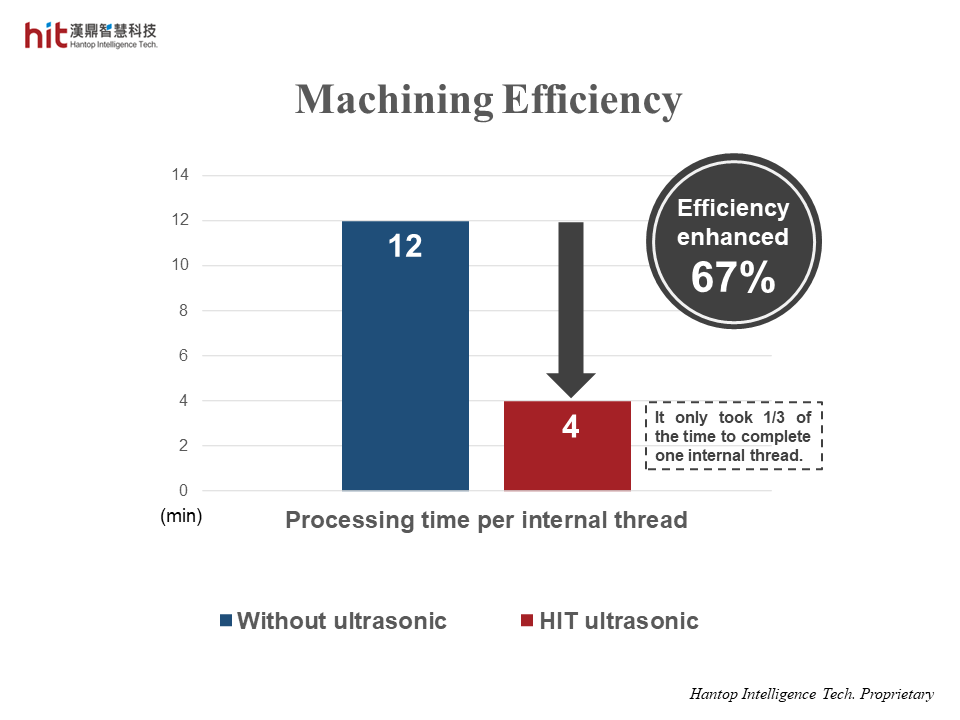

Tungsten Carbide M2 Internal Threading : Machining Efficiency

(Figure 3. the machining efficiency was enhanced 67% with HIT Ultrasonic on M2 internal threading of tungsten carbide)

- (Under the same feed per revolution) With HIT ultrasonic, both rotation speed (from 10,000rpm to 30,000rpm) and feed rate (from 20mm/min to 60mm/min) can be enhanced 3 times higher than the ones suggested by the tooling supplier.

- The processing time of completing one internal thread was reduced to 1/3 of the processing time without ultrasonic.

- With HIT ultrasonic, it helped reduce the cutting force under high-speed machining, which accomplished the machining of M2 internal thread on tungsten carbide.

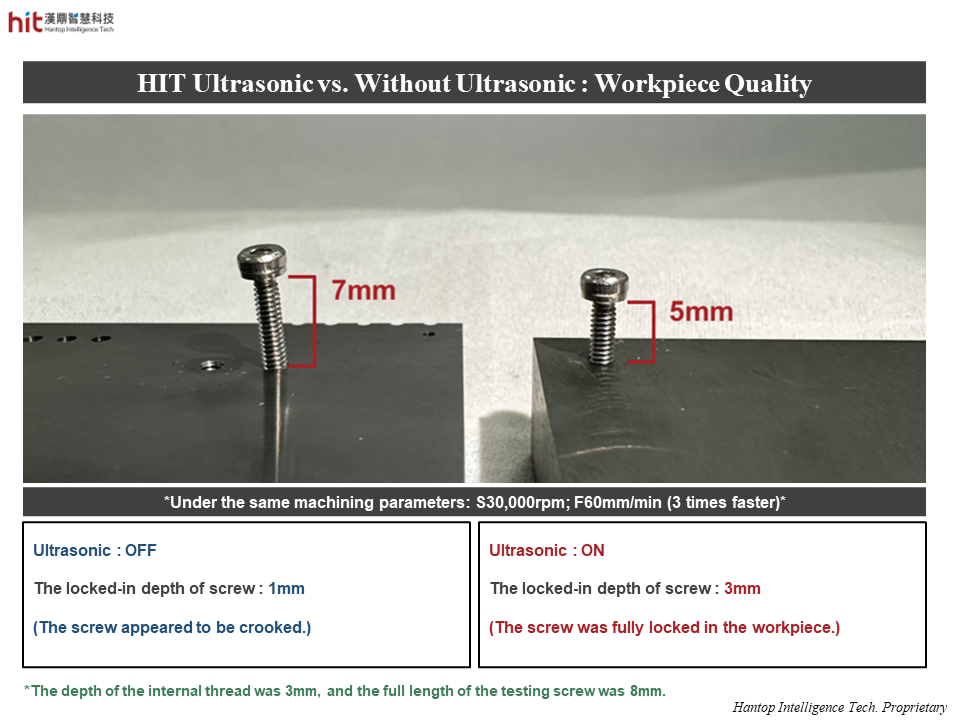

Tungsten Carbide M2 Internal Threading : Workpiece Quality

(Figure 4. the comparison of workpiece quality between HIT Ultrasonic and Without Ultrasonic on M2 internal threading of tungsten carbide workpiece)

- With HIT ultrasonic, the high frequency micro-vibration allowed for intermittent contact between the tool and workpiece, which greatly helped reduce cutting heat.

- The reduction in both cutting force and cutting heat under high-speed machining contributed to the completeness of the M2 internal thread profile.

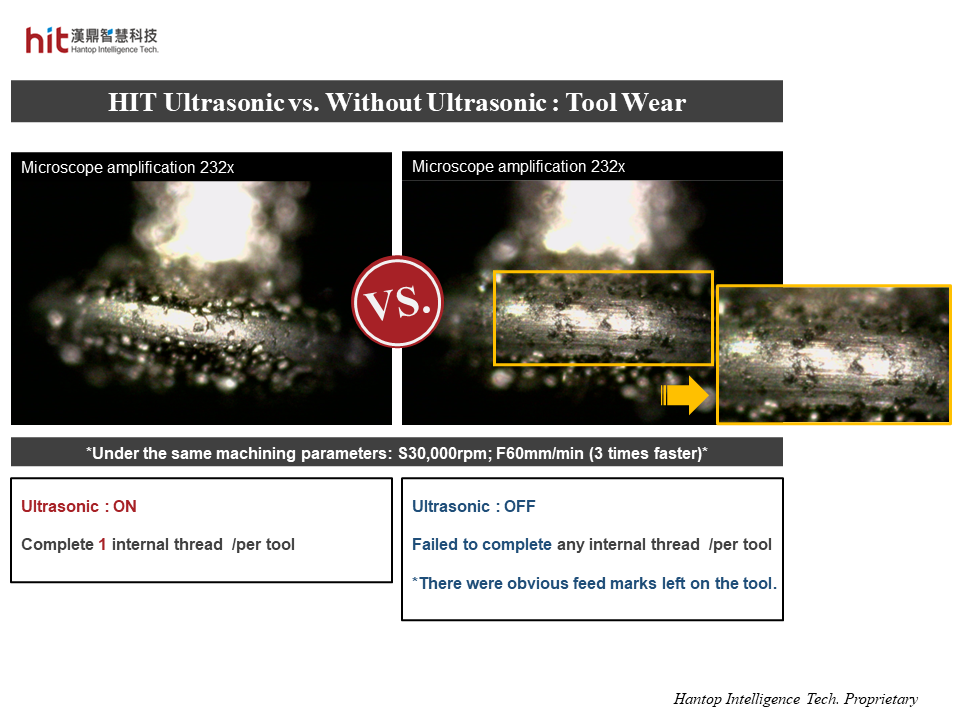

Tungsten Carbide M2 Internal Threading : Tool Life

(Figure 5. the comparison of tool wear between HIT Ultrasonic and Without Ultrasonic on M2 internal threading of tungsten carbide)

- The optimized machining parameters (3 times higher than the ones suggested by the tooling supplier-S30,000rpm; F60mm/min) were to present the best of ultrasonic-assisted machining technology, and as an accelerated test on the tool life.

- Under the high-speed ultrasonic-assisted machining process, the tool can complete one M2 internal thread; whereas the tool failed to complete any internal threads without ultrasonic and even appeared to have serious tool wear (obvious feed marks left on the tool).

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - enhanced 67%

📈 Quality - complete profile

⚙️ Tool Life - improved