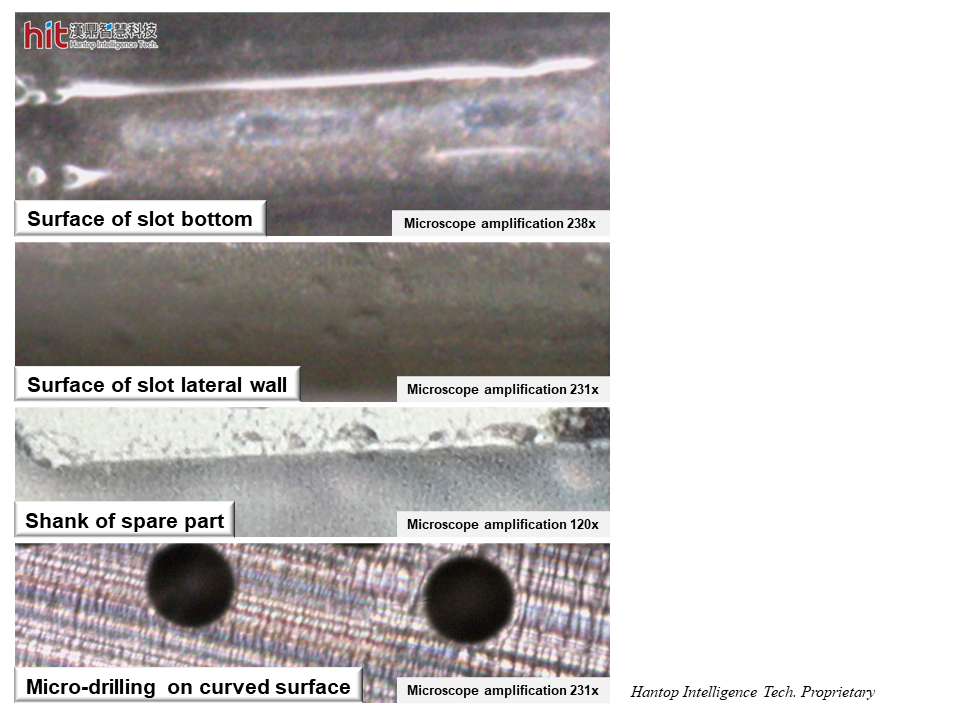

(Figure 1. HIT BT30 ultrasonic machining module was used for micro-milling and micro-drilling of AISI-420 stainless steel medical spare parts)

HIT's Goal in Machining AISI-420 Stainless Steel

The ultimate goal is to help enhance product yield rate for our customer. Through the assistance of HIT Ultrasonic, customer could eliminate the manual refining process and achieve even better surface quality with great reduction in burrs.

Ultrasonic-Assisted Machining AISI-420 Stainless Steel Results

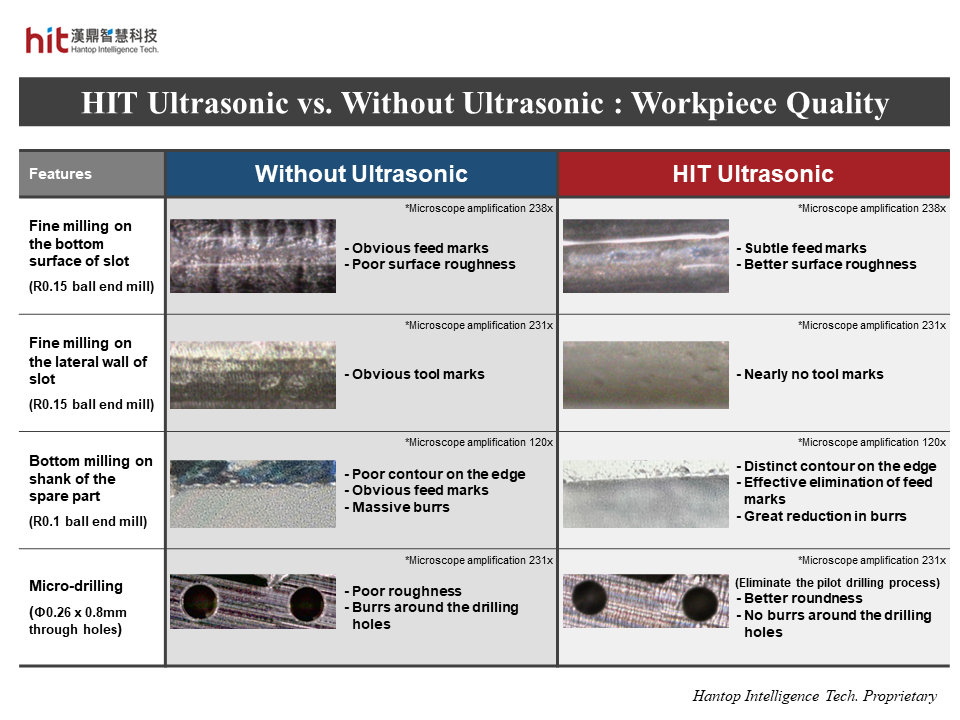

AISI-420 Stainless Steel Micro-Milling & Micro-Drilling : Workpiece Quality

(Figure 2. HIT ultrasonic-assisted micro-milling and micro-drilling of AISI-420 stainless steel for medical spare parts can improve surface quality, greatly reduce burrs, and have better hole roundness without pilot drilling process)

- Without ultrasonic, high cutting forces appeared at the chisel of ball end mill. This caused vibration when the tool started pushing and squeezing the material, and eventually left obvious feed marks on the surface of workpiece.

- Along with the work-hardening characteristics of stainless steel, the cutting ability of the chisel could not overcome the plastic deformation of stainless steel. The tool failed to cut off the material, which left serious tool marks and massive burrs on the workpiece.

- With HIT ultrasonic, the high frequency micro-vibration helped reduce the cutting force at the chisel of ball end mill. This allowed the tool to cut off the material with easier chip removal, which helped improve the surface roughness of workpiece and have great reduction in burrs.

- Especially when micro-drilling on a curved surface, the lowered cutting force also prevented the tool from deflection. As a result, with HIT ultrasonic, there could be better roundness in drilling holes without pilot drilling process.

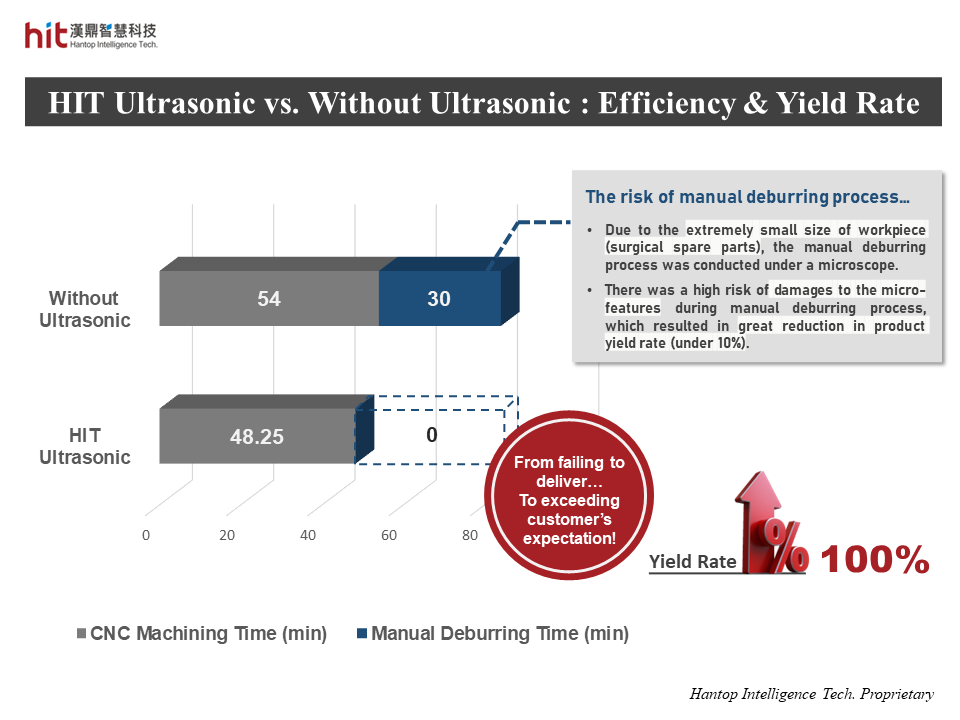

AISI-420 Stainless Steel Micro-Milling & Micro-Drilling : Efficiency & Yield Rate

(Figure 3. HIT ultrasonic-assisted micro-milling and micro-drilling of AISI-420 stainless steel for medical spare parts can successfully eliminate the manual refining process, and enhance the product yield rate from 10% to 100%)

- Without ultrasonic, the surface of workpiece was terrible with massive burrs after CNC machining process. It would then require blasting and manual deburring process in order to refine the workpiece quality.

- Since the workpiece size was extremely small, manual deburring process could cause risks including damages to the micro-features or failing to remove tool marks after blasting.

- Moreover, the refining process could not overcome poor roundness in micro-drilling on a curved surface.

- The true benefit that HIT ultrasonic brought to the customer regarding the machining process was the increase of product yield rate to 100% by CNC machining process.

- Without having to face the risks of poor yield rate due to manual refining process, the products could achieve customer's standards and even exceed their expectation.

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency & Yield Rate - elimination of manual refining process, and product yield rate was raised from under 10% to 100%

📈 Quality - great improvement in surface roughness with no obvious feed marks or burrs, and have great roundness in micro-drilling on cruved surface without pilot drilling process