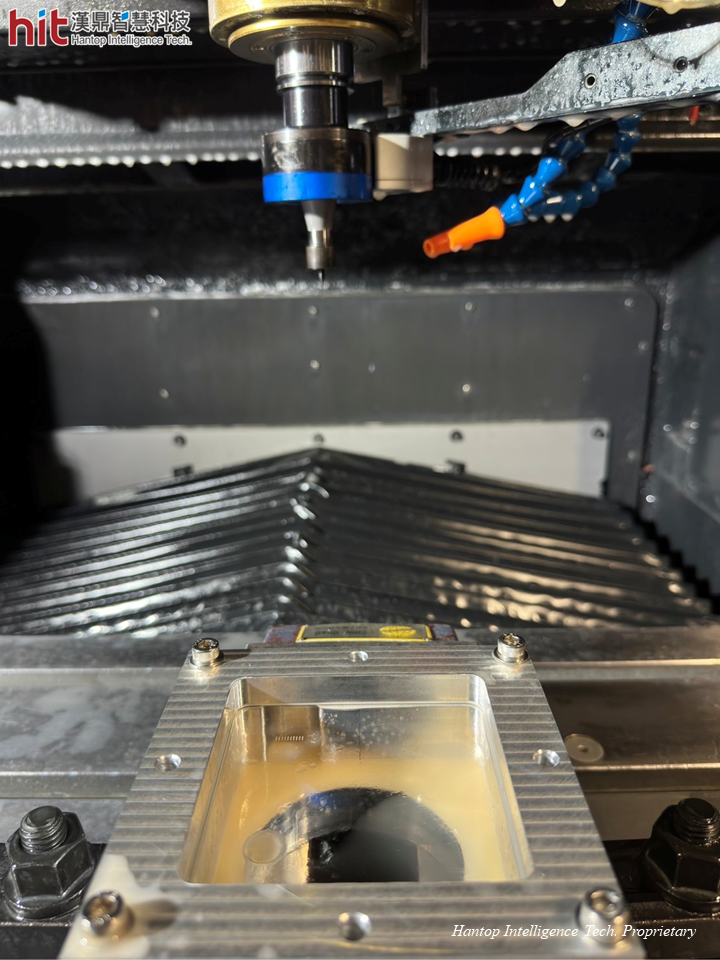

(Figure 1. HSK-E40 ultrasonic toolholder was used on soda-lime glass micro-drilling)

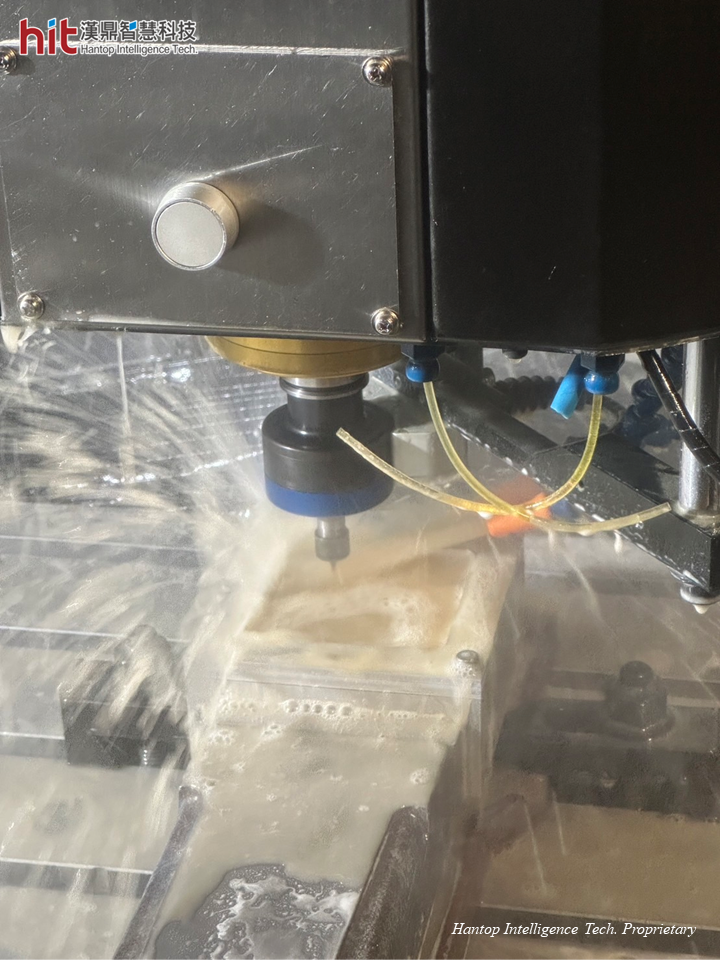

(Figure 2. ultrasonic-assisted micro-drilling on soda-lime glass workpiece)

HIT's Goal in Machining Soda-Lime Glass

The goal is to raise the machining efficiency, while reducing the size of edge-cracks on micro-drilling of soda-lime glass.

Ultrasonic-Assisted Machining Soda-Lime Glass Results

Soda-Lime Glass Micro-Drilling : Machining Efficiency

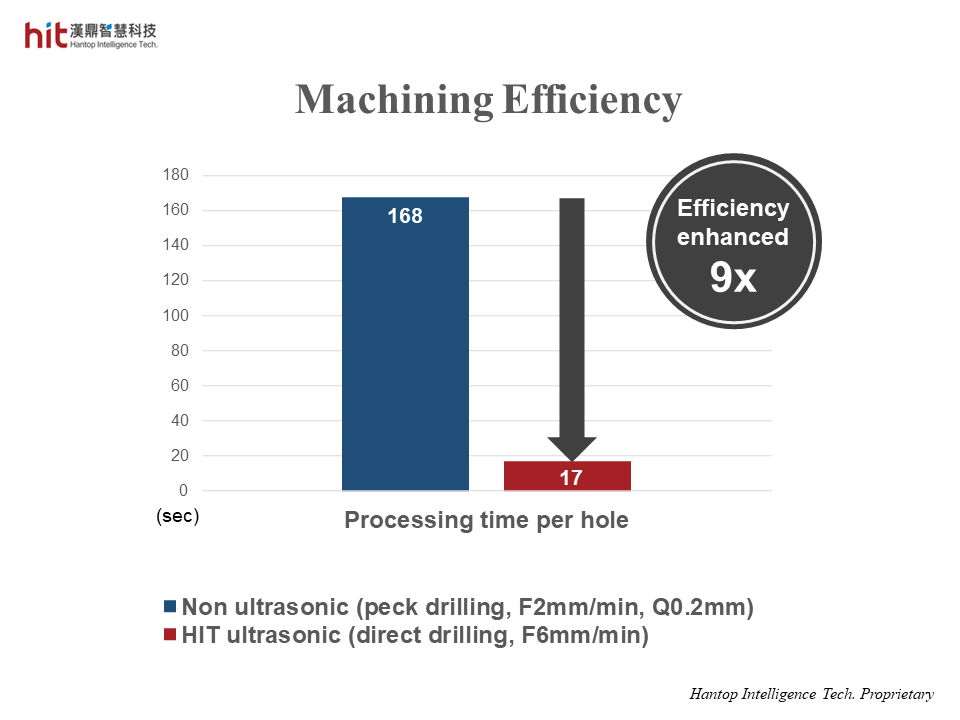

(Figure 3. the machining efficiency was enhanced 9x with HIT Ultrasonic on micro-drilling soda-lime glass)

The overall machining efficiency was enhanced 9 times faster than that without ultrasonic.

- With HIT's ultrasonic-assisted machining technology, the pilot drilling process could be eliminated, and the conventional peck drilling cycle was replaced with direct drilling.

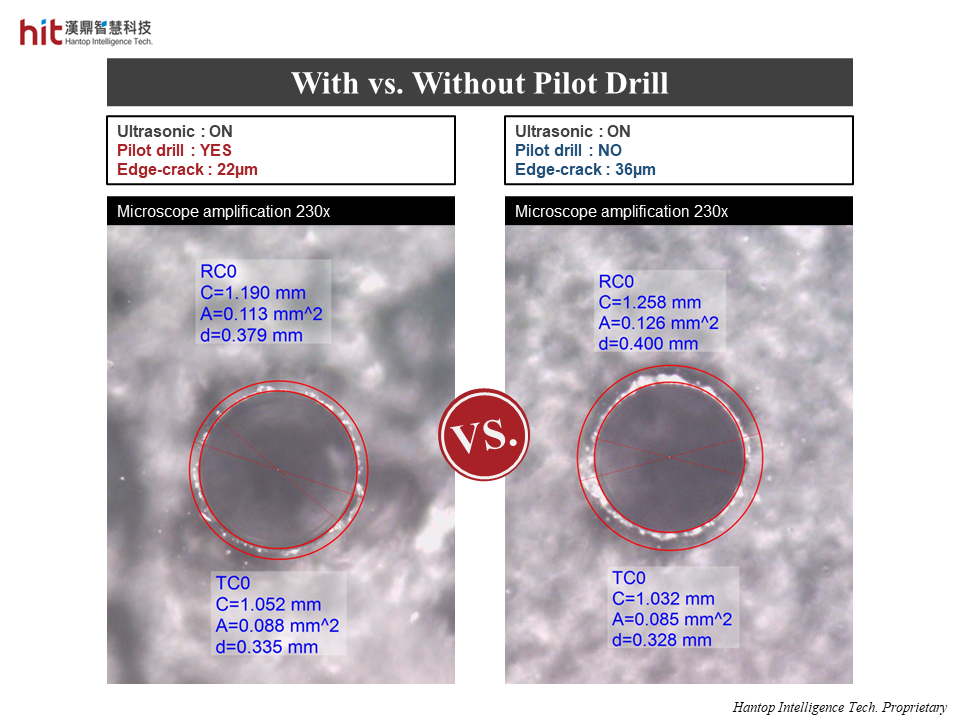

(Figure 4. with HIT Ultrasonic, the size of edge-crack remained small even without pilot drill)

- The high-frequency micro-vibration of HIT's ultrasonic-assisted machining technology helps reduce the thrust force and torque, the feed rate was enhanced 3x while maintaining small edge-cracks under the same rotation speed (12,000rpm).

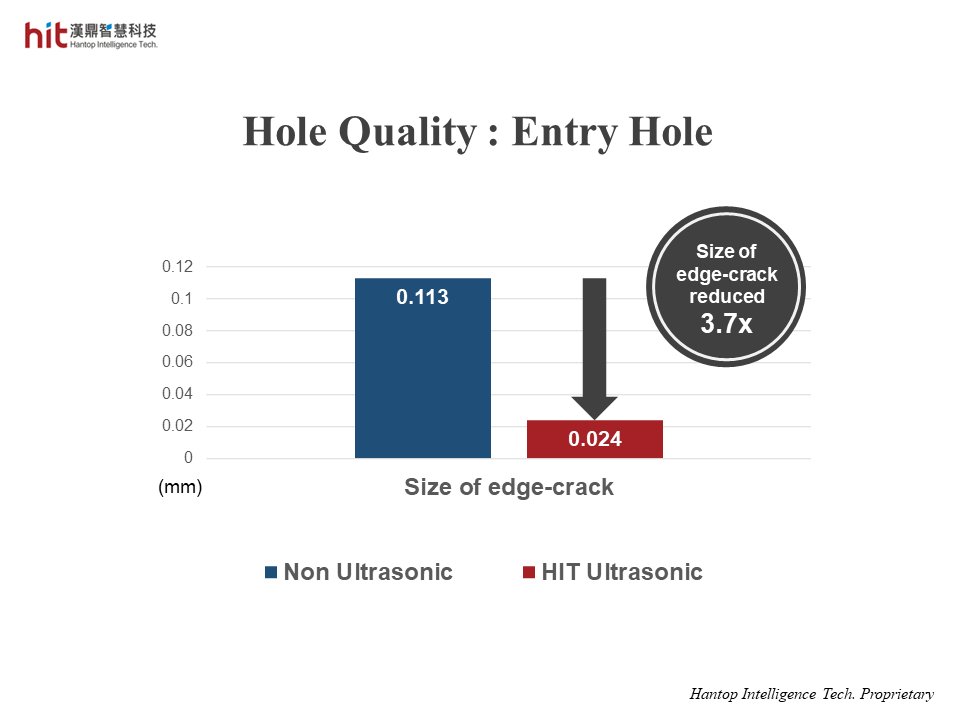

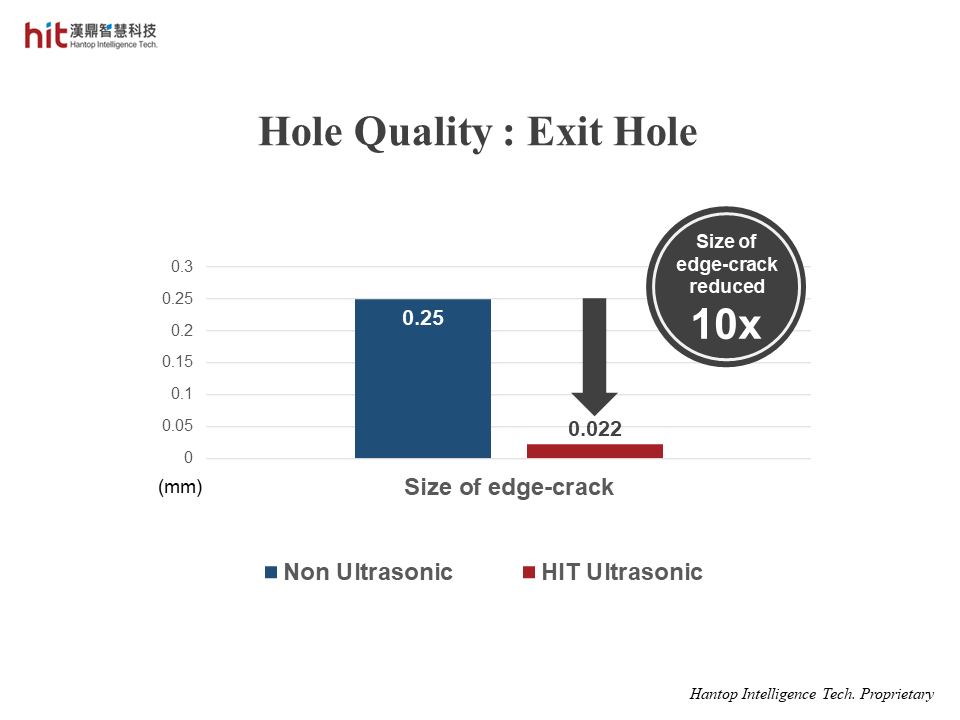

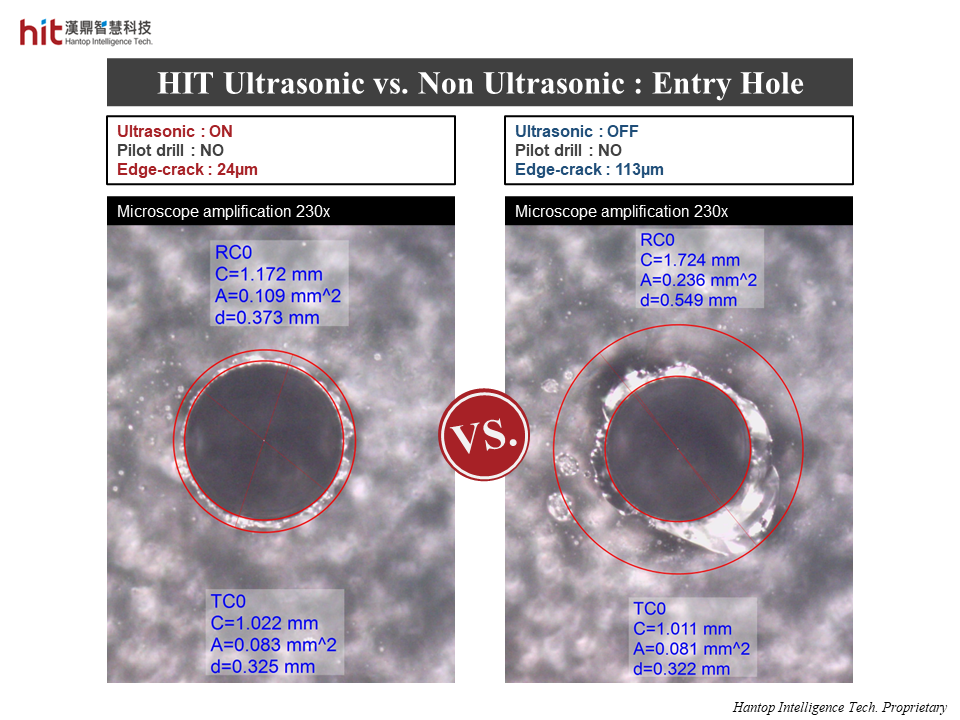

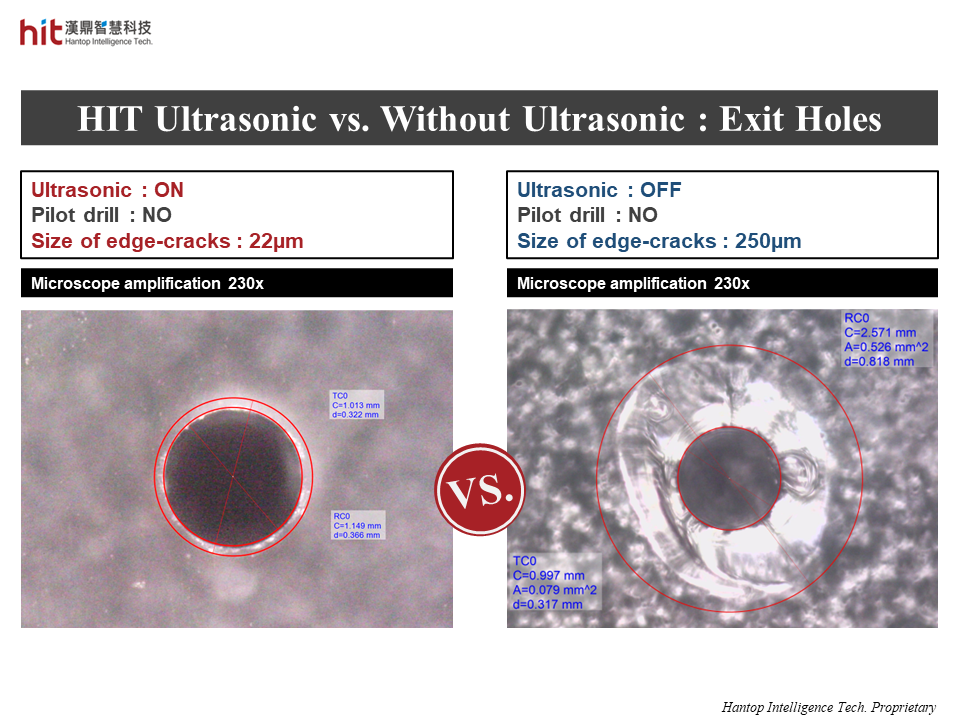

Soda-Lime Glass Micro-Drilling : Hole Quality

(Figure 5. the size of edge-crack around entry holes was reduced 3.7x with HIT Ultrasonic on micro-drilling soda-lime glass)

(Figure 6. the size of edge-crack around exit holes was reduced 10x with HIT Ultrasonic on micro-drilling soda-lime glass)

The overall hole quality was greatly enhanced with the size of edge-cracks around entry holes reduced 3.7x and the size of edge-cracks around exit holes reduced 10x.

(Figure 7. comparison of the size of edge-cracks around entry holes between HIT Ultrasonic and Non Ultrasonic)

(Figure 8. comparison of the size of edge-cracks around exit holes between HIT Ultrasonic and Non Ultrasonic)

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - 9x faster than that without ultrasonic

📈 Quality - hole quality enhanced 10x better than that without ultrasonic (size of edge-crack is greatly reduced to 22µm)