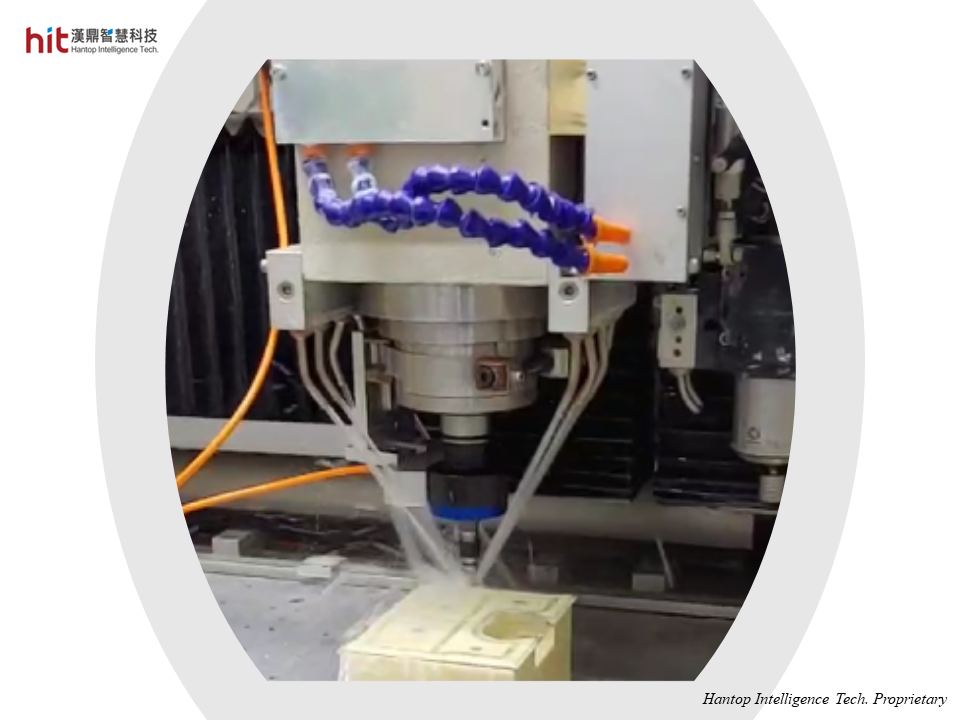

(Figure 1. HSK-E40 ultrasonic toolholder was used on soda-lime glass edge grinding)

(Figure 2. the schematic figure of soda-lime glass edge grinding workpiece)

HIT's Goal in Machining Soda-Lime Glass

The goal is to raise the machining efficiency while maintaining acceptable workpiece quality (< 50µm). The stability in tool life is also required to be improved.

Ultrasonic-Assisted Machining Soda-Lime Glass Results

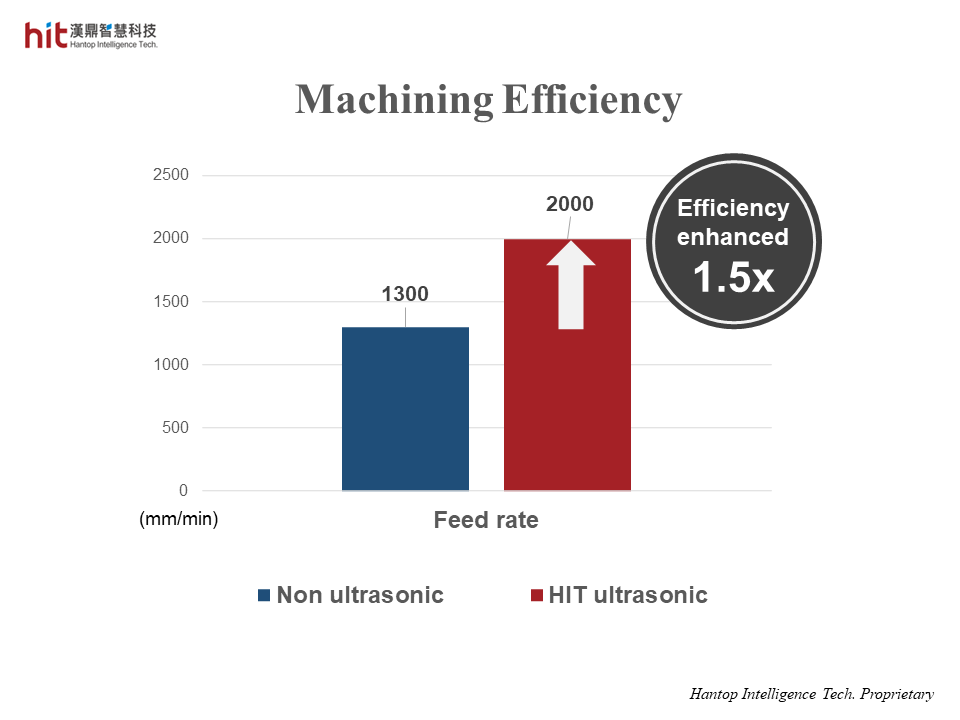

Soda-Lime Glass Edge Grinding : Machining Efficiency

(Figure 3. the machining efficiency was enhanced 1.5x with HIT Ultrasonic on edge grinding soda-lime glass)

Conventionally, with such low spindle rotation (21,000rpm), it is impossible to raise the cutting speed and feed rate.

With HIT Ultrasonic, even with low spindle rotation (21,000rpm), the cutting speed and feed rate can be raised 1.5 times faster than that without ultrasonic (under the circumstances of maintaining acceptable workpiece quality and the stability in tool life), resulting in the increase in the overall machining efficiency.

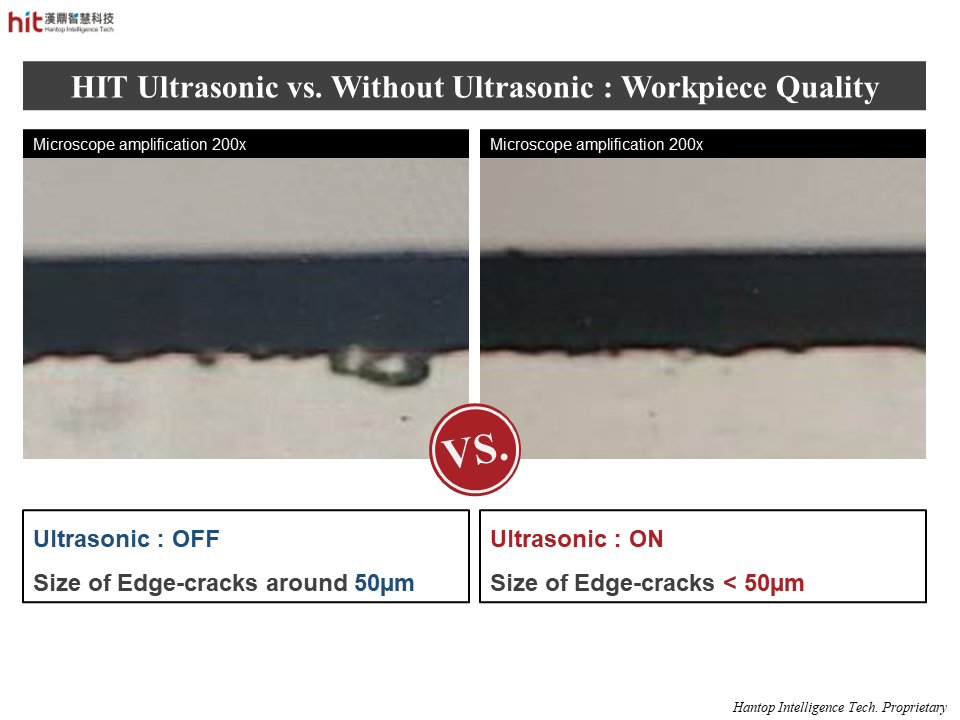

Soda-Lime Glass Edge Grinding : Workpiece Quality

(Figure 4. the size of edge-cracks in all 400 pieces of soda-lime glass is within customer's requirement on the quality with HIT ultrasonic)

Throughout the entire machining trials, HIT completed 400 pieces of edge grinding on soda-lime glass.

All of which was measured and in compliance within customer's requirement on the quality (< 50µm).

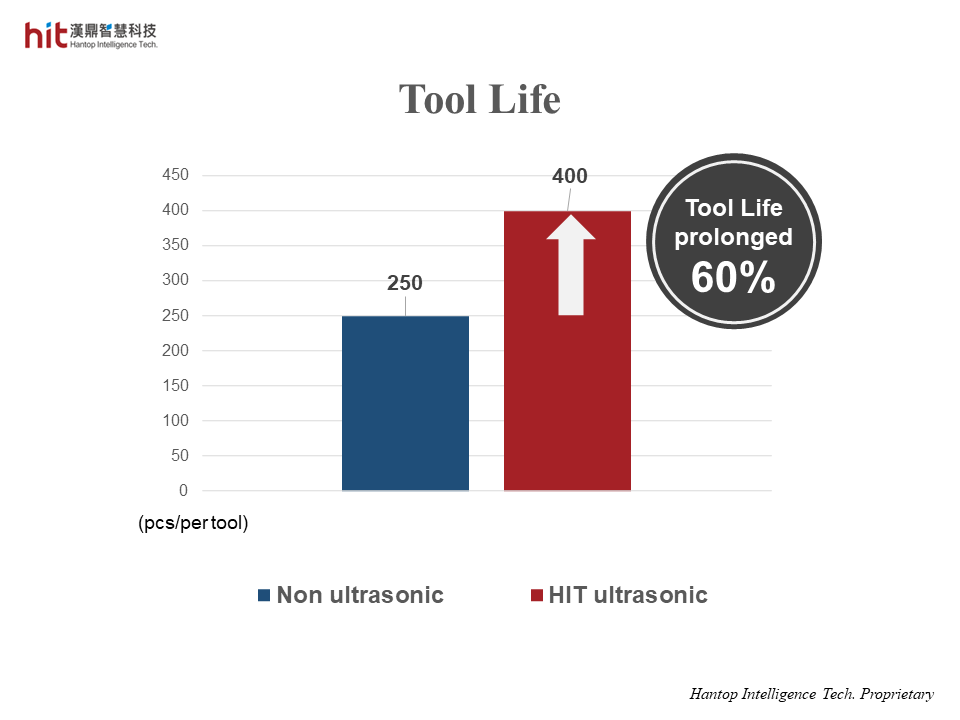

Soda-Lime Glass Edge Grinding : Tool Life

(Figure 5. the tool life was prolonged 60% with HIT Ultrasonic on edge grinding soda-lime glass)

With HIT Ultrasonic, the high frequency micro-vibration greatly helped improve the chip removal process.

This allowed for the reduction in both cutting force and cutting heat, resulting in the improvement of 60% longer tool life (from 250 pcs/per tool to 400 pcs/per tool).

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - enhanced 1.5 times faster

📈 Quality - all 400 pieces are well-maintained and in compliance with client's requirement

⚙️ Tool Life - enhanced 60%