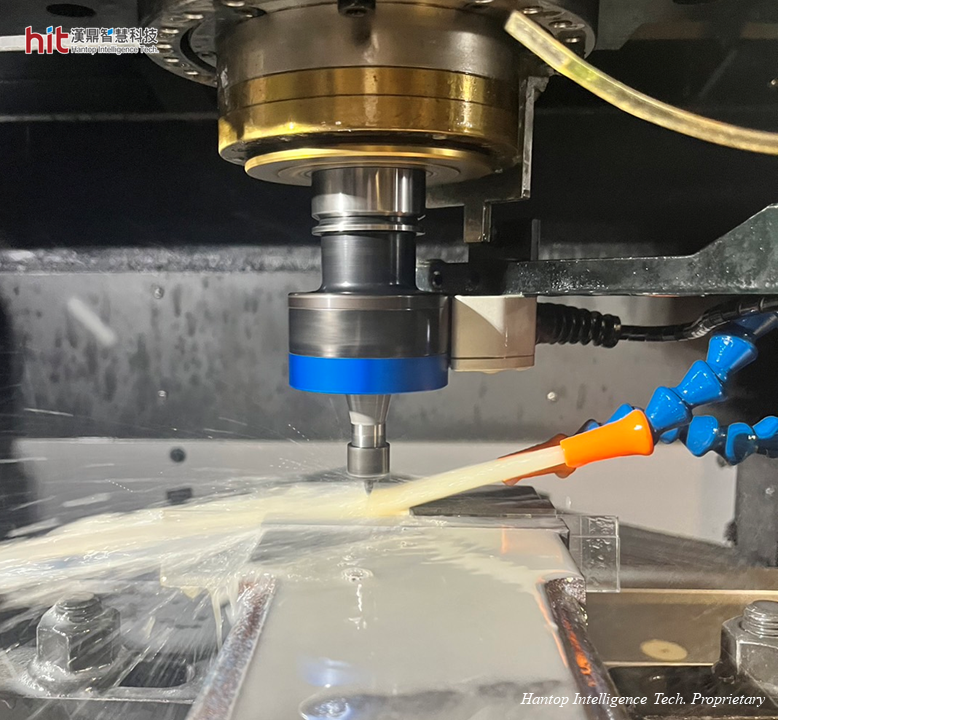

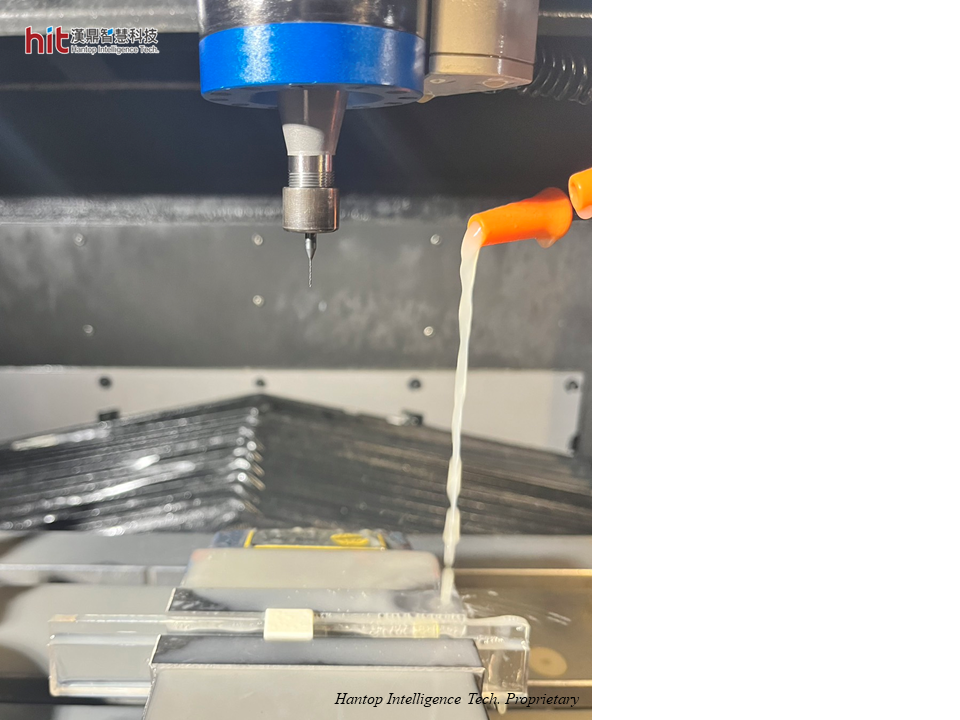

(Figure 1. HSK-E40 ultrasonic toolholder was used on aluminum oxide ceramic micro-drilling)

(Figure 2. aluminum oxide ceramic workpiece and HSK-E40 ultrasonic toolholder after machining)

HIT's Goal in Machining Aluminum Oxide (Al2O3) Ceramic

The goal is to enhance the machining efficiency, while improving the hole quality (especially exit holes) and maintaining the stability in tool life.

Ultrasonic-Assisted Machining Aluminum Oxide (Al2O3) Ceramic Results

Aluminum Oxide (Al2O3) Ceramic Micro-Drilling : Machining Efficiency

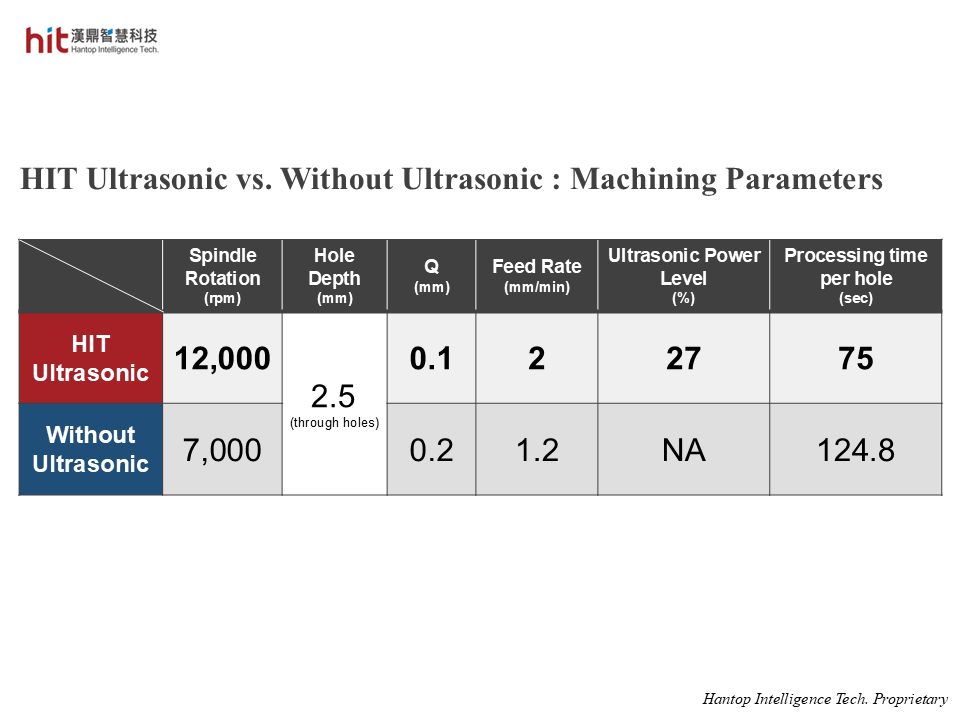

(Figure 3. the comparison of machining parameters between HIT Ultrasonic and without Ultrasonic)

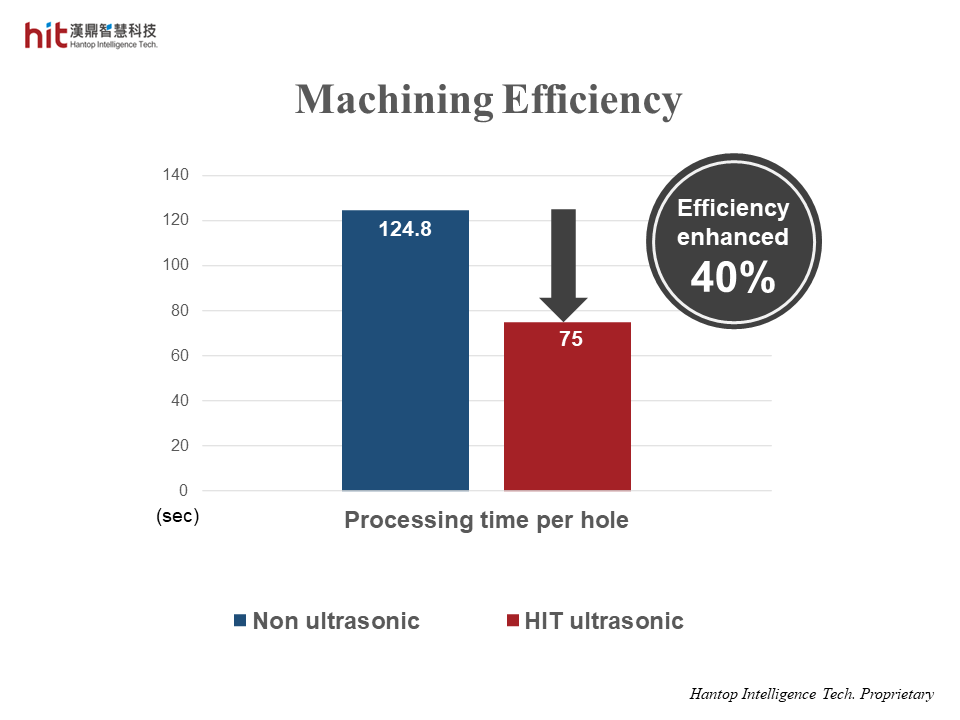

- (Under the same feed per revolution) By raising the rotation speed from 7,000rpm to 12,000rpm, the feed rate would also be enhanced from 1.2mm/min to 2mm/min. This allowed the machining efficiency to be enhanced 40%.

- With HIT Ultrasonic, the high frequency micro-vibration helped reduce the cutting force. The drilling process did not have to slow down around exit holes for fear of serious edge-cracks due to great cutting force. As a result, HIT ultrasonic-assisted machining helped save up more time of the entire process.

(Figure 4. the machining efficiency was enhanced 40% with HIT Ultrasonic on micro-drilling aluminum oxide)

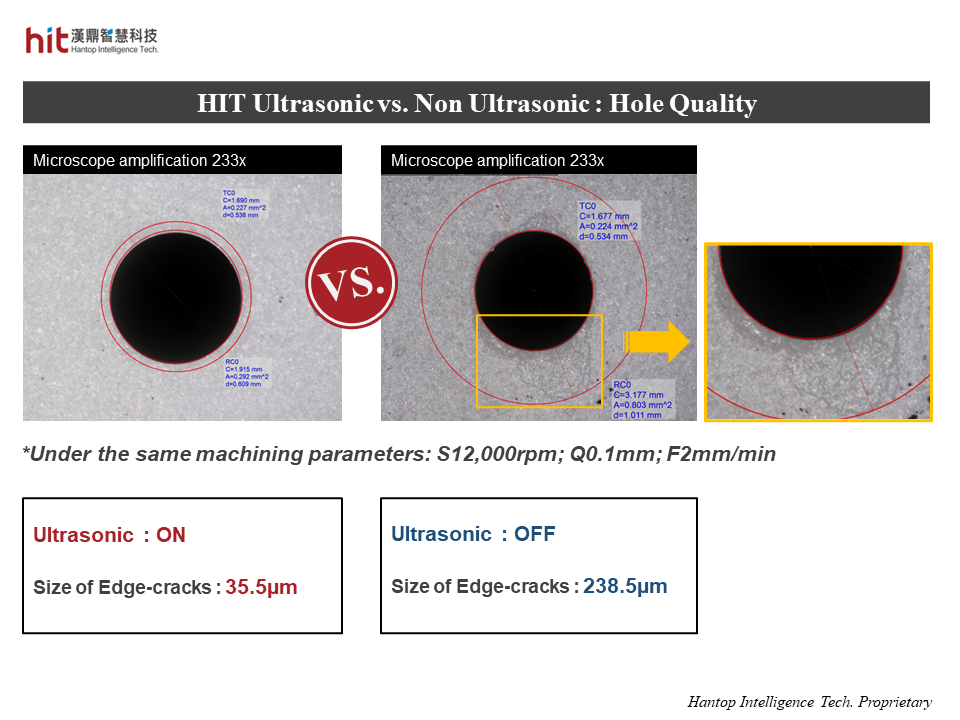

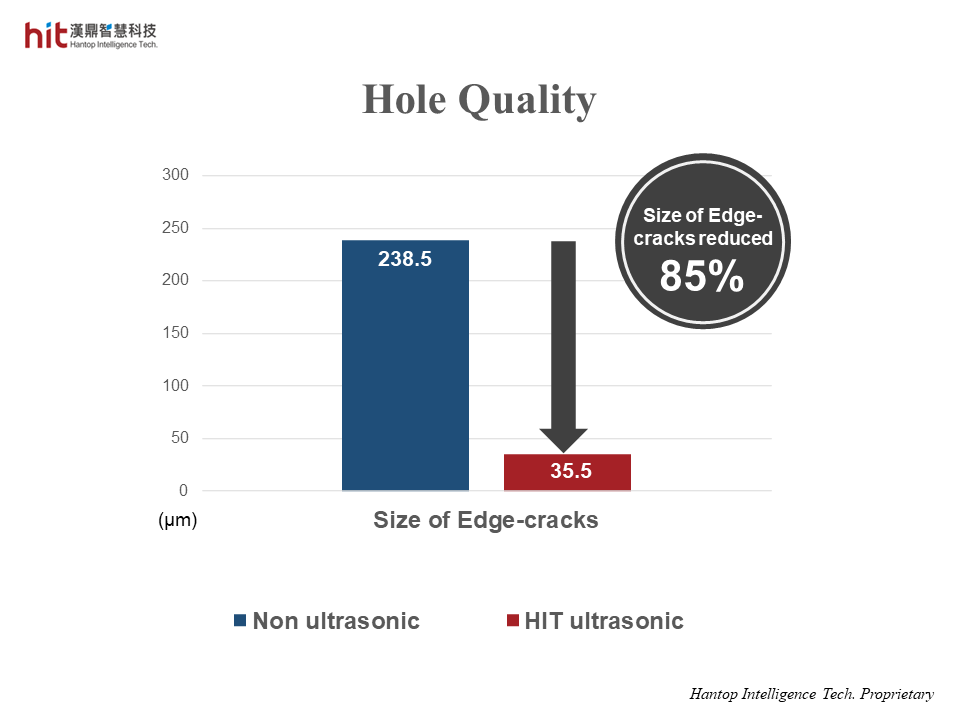

Aluminum Oxide (Al2O3) Ceramic Micro-Drilling : Hole Quality

(Figure 5. the comparison of exit hole quality between HIT Ultrasonic and Non Ultrasonic on micro-drilling aluminum oxide)

- With HIT Ultrasonic, the high frequency micro-vibration helped reduce the cutting force. Especially when drilling through the exit holes, the lowered cutting force allowed for a 85% reduction in the size of edge-cracks (from 238.5µm to 35.5µm).

- In conventional CNC machining, the cutting force could be really strong and hard to control. This may cause great extrusion between the tool and workpiece, resulting in massive edge-cracks around the drilling holes.

(Figure 6. the hole quality was enhanced 85% for the great reduction in edge-cracks with HIT Ultrasonic on micro-drilling aluminum oxide)

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - enhanced 40%

📈 Quality - hole quality enhanced 85% (size of edge-crack reduced to 35.5µm)

⚙️ Tool Life - improved