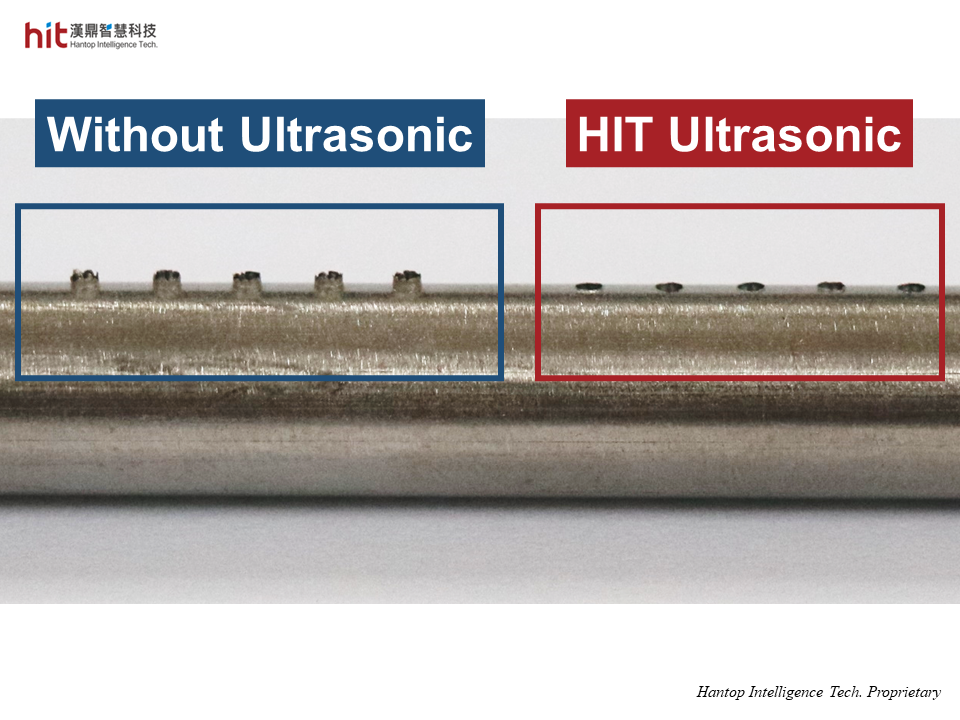

(Figure 1. HIT HSK-A63 ultrasonic machining module was used for micro-drilling through holes on curved surface of AISI-304 stainless steel)

HIT's Goal in Micro-Drilling Through Holes on AISI-304 Stainless Steel

The goal is to prevent burrs around the exit holes on curved surface of 304 stainless steel and to reduce tool wear, by using CNC machining with HIT ultrasonic-assisted machining technology.

Ultrasonic-Assisted Micro-Drilling Through Holes on AISI-304 Stainless Steel: Machining Results

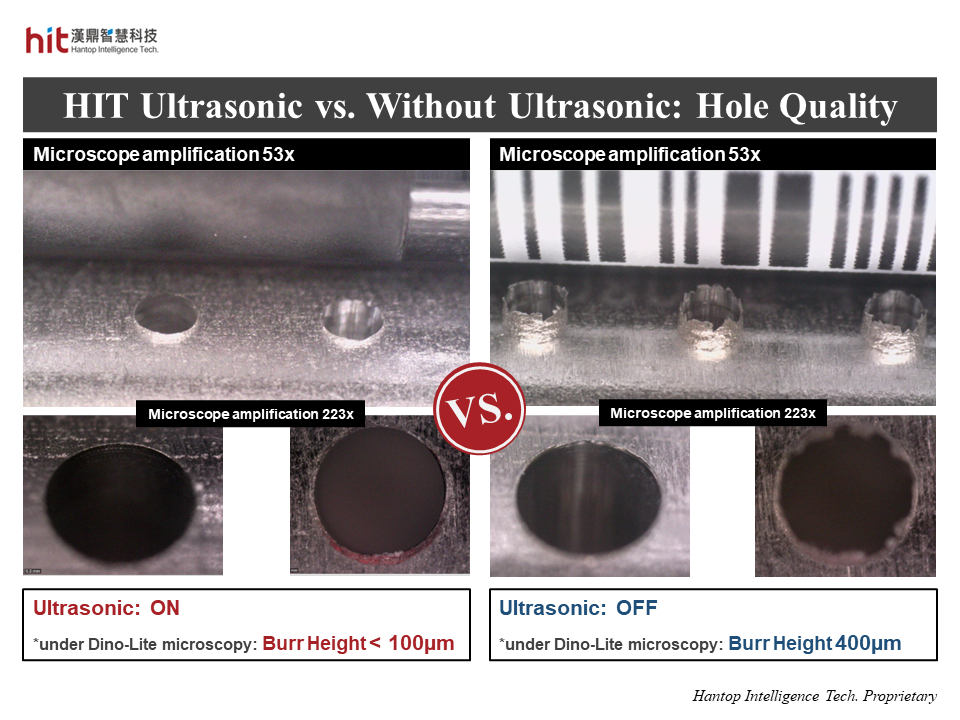

AISI-304 Stainless Steel Micro-Driling Through Holes: Hole Quality

(Figure 2. HIT ultrasonic-assisted micro-drilling through holes on curved surface of 304 stainless steel greatly helped reduce burss around exit holes)

- In this cutting test trial (under the same machining parameters without ultrasonic), the material was hard to cut off due to its material properties. Along with poor chip evacuation, cutting force was increased during the machining process. This resulted in massive burrs around exit holes.

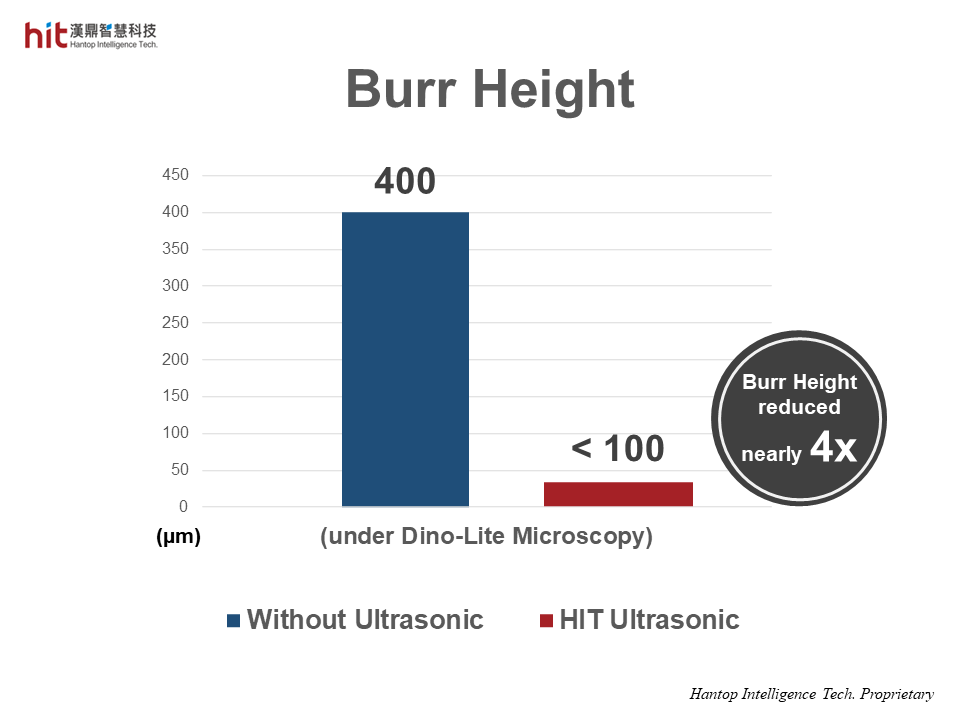

- With HIT ultrasonic, the high frequency micro-vibration helped reduce cutting forces. This prevented the tool from deflection, which helped achieve good entry hole quality. In the meantime, better chip evacuation allowed the tool to cut off the material more easily. This effectively reduced nearly 4x of burr height around the exit holes.

(Figure 3. HIT HSK-A63 ultrasonic machining module was used for micro-drilling through holes on curved surface of 304 stainless steel, and helped reduce nearly 4x of burr height around exit holes)

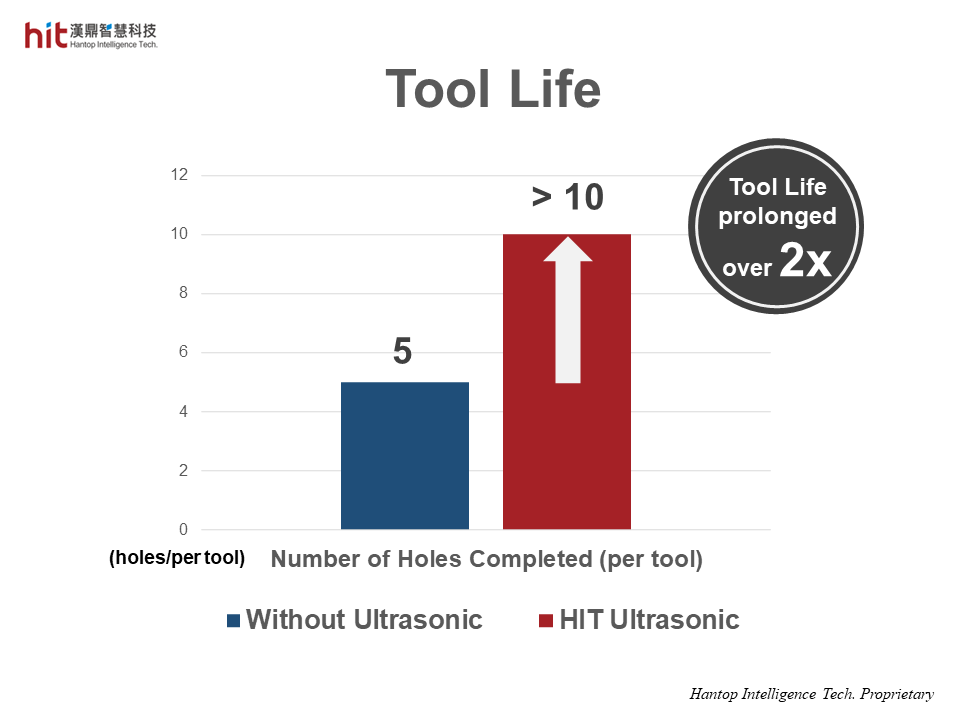

AISI-304 Stainless Steel Micro-Drilling Through Holes: Tool Life

(Figure 4. HIT HSK-A63 ultrasonic machining module was used for micro-drilling through holes on curved surface of 304 stainless steel, resulting in over 2x longer tool life compared to that without ultrasonic)

- In conventional machining (without ultrasonic), the material was hard to cut off due to its material properties. Along with poor chip evacuation, entangled chips were easily stuck on the tool during the machining process, which resulted in serious tool wear.

- In this cutting test trial, under the same machining parameters without ultrasonic, it only completed 5 through holes before tool breakage.

- With HIT ultrasonic (under the same machining parameters), high frequency micro-vibration helped reduce cutting forces. With better chip evacuation, the tool could cut off the material more easily, preventing from entangled chips on the tool. This greatly reduced tool wear, and effectively prolonged over 2x of tool life.

HIT Ultrasonic Technology Achievements in Micro-Drilling Through Holes on AISI-304 Stainless Steel

📈 Hole Quality - burr height reduced nearly 4x without plunge milling

⚙️ Tool Life - prolonged over 2x longer