~ 03.11 (六) 的複本 的複本 (5).png)

HIT Ultrasonic @ SEMICON Taiwan 2023 | Advanced-Material Machining Solution Modules

SEMICON Taiwan 2023, the three-day exhibition event, came to a successful conclusion from September 6th to 8th! This year, the exhibition revolved around the theme of innovation and sustainability - "Inspire Innovation. Empower Sustainability." The event achieved record-breaking attendance as well as venue size, attracting over 62,000 visitors during the three-day event.

【HIT @ SEMICON Taiwan 2023: Crowd at Booth & Product Display】

(Figure 1. Hantop Intelligence Tech. attended SEMICON Taiwan 2023)

(Figure 2. Founder and CTO of HIT - Professor Michael Chen also came and had technological knowledge exchange with semiconductor industrial experts during SEMICON Taiwan 2023)

During this year's exhibition, HIT displayed its ultrasonic-assisted machining module, designed to provide solution for the machining of advanced-material components (such as showerhead, electrostatic chuck - E-chuck - ESC, wafer susceptors) used in semiconductor manufacturing processes (such as etching, thin-film, MOCVD).

Thanks to HIT's active presence and efforts invested in overseas semiconductor giants (including HIT's global agents in South Korea and Japan) in recent years, it has garnered increasing attention from international semiconductor industry leaders such as Applied Materials, TEL, etc. Professionals within the industry also paid visits to HIT's booth during the exhibition to learn more about innovative solutions for advanced-materials machining using ultrasonic-assisted machining technology in the semiconductor manufacturing process.

(Figure 3. HIT attracted a large crowd of experts to come to understand ultrasonic-assisted machining module products during SEMICON Taiwan 2023)

(Figure 4. HIT attracted a large crowd of experts to come to understand ultrasonic-assisted machining technology during SEMICON Taiwan 2023)

【HIT @ SEMICON Taiwan 2023: Smart Manufacturing Journey - Meet-the-expert Speech Event】

On the final day of the exhibition, HIT's Director of Product Development participated in the "Meet-the-expert" event held in SEMICON Taiwan 2023 Smart Manufacturing Journey. The speech primarily focused on sharing insights into HIT's ultrasonic high-frequency micro-vibration machining mechanism and how it can bring more innovation, less energy consumption, and more efficiency to the machining process of semiconductor manufacturing components.

(Figure 5. SEMICON Taiwan 2023 Meet-the-expert: HIT ultrasonic-assisted machining of advanced-material used as key components in semiconductor manufacturing process)

(Figure 6. SEMICON Taiwan 2023 Meet-the-expert: HIT ultrasonic-assisted grinding of SiC silicon carbide as semiconductor wafer susceptors)

In the machining of semiconductor manufacturing components, such as silicon carbide showerheads, aluminum oxide ceramic electrostatic chucks (E-chucks, ESC), and silicon carbide wafer susceptors/carriers, HIT's ultrasonic-assisted machining module has been validated to bring multiple added-value to customers. Apart from higher efficiency, improved surface and hole quality, and longer tool life, the technology also helps customers optimize their overall processes. This optimization brings reduction in labor and time costs while enhancing product yield as well as capacity.

(Figure 7. SEMICON Taiwan 2023 Meet-the-expert: HIT attracted a large crowd of experts to come to learn more about ultrasonic-assisted machining technology)

We would like to express our gratitude to the industrial experts who visited HIT's booth during the exhibition and attended the meet-the-expert event. HIT is committed to delivering high-quality products and professional services to our customers. In the upcoming two quarters, we plan to introduce even more innovative products and technology as machining solutions that will revolutionize semiconductor manufacturing process! ✨

【HIT @ SEMICON Taiwan 2023: Ultrasonic-assisted Machining Solution for Semiconductor Advanced-Materials】

(Figure 8. HIT ultrasonic-assisted machining module - semiconductor advanced-material machining solution)

HIT's ultrasonic-assisted machining module plays a significant role in the semiconductor industry, particularly for critical components (e.g., silicon carbide showerheads, ceramic electrostatic chucks, silicon carbide wafer susceptors/carriers) used in the semiconductor manufacturing processes (such as etching, thin-film, MOCVD). The application also includes quartz glass microfluidic devices used in the semiconductor manufacturing testing or trial process.

These critical components typically share several characteristics, including small and fine features (such as micro-holes and very small internal threads), high surface quality requirements, and the need to avoid generating extensive chipping, edge-cracks or sub-surface damage. Due to the high-quality standards required in semiconductor wafer manufacturing process, key components used in the processing equipment must also meet these requirements.

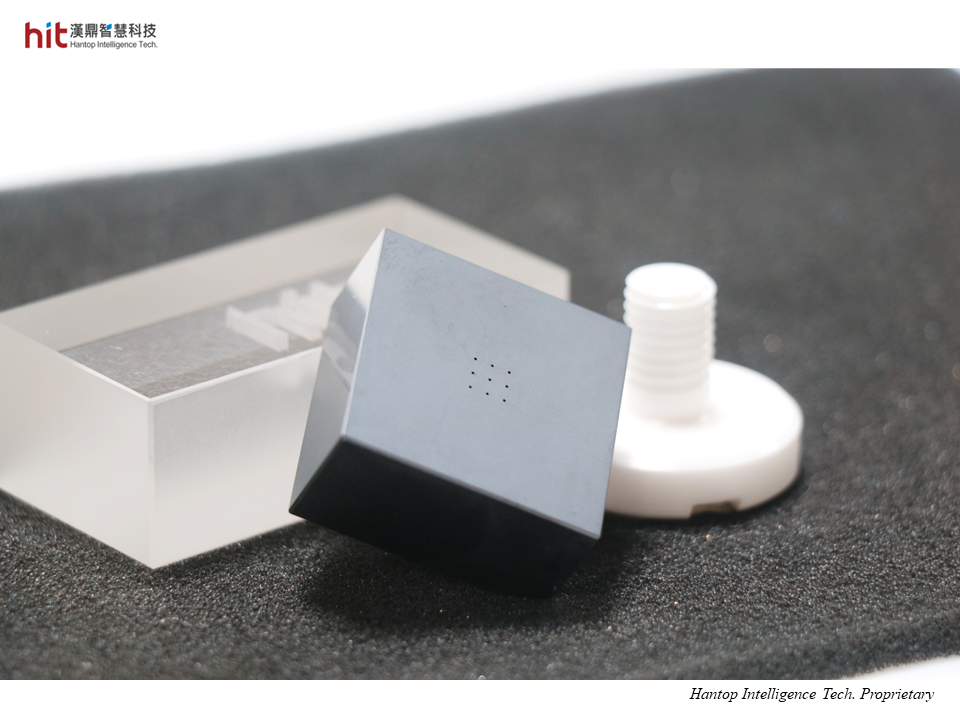

(Figure 9. HIT ultrasonic-assisted machining of SiC silicon carbide micro-drilling)

Showerheads are crucial components in semiconductor etching and MOCVD process chamber. In wafer manufacturing, showerheads are used to evenly distribute external reactant gases or fluids onto the wafers for acid etching. Therefore, the quality of the micro-holes on showerheads, including the quality of exit holes, hole walls, straightness, and roundness, will directly impact the yield of the entire wafer fabrication process.

Silicon carbide (SiC) is a popular compound semiconductor material due to its low energy consumption, high-temperature resistance, corrosion resistance, and wear resistance. However, when micro-drilling SiC ceramic, conventional machining techniques face high cutting forces, leading to serious and extensive edge-cracks that fails to meet semiconductor product quality requirements.

💡 Learn more about HIT Ultrasonic-assisted Machining of SiC (Silicon Carbide) Micro-drilling: 1.5x smaller edge-cracks, 3x longer tool life

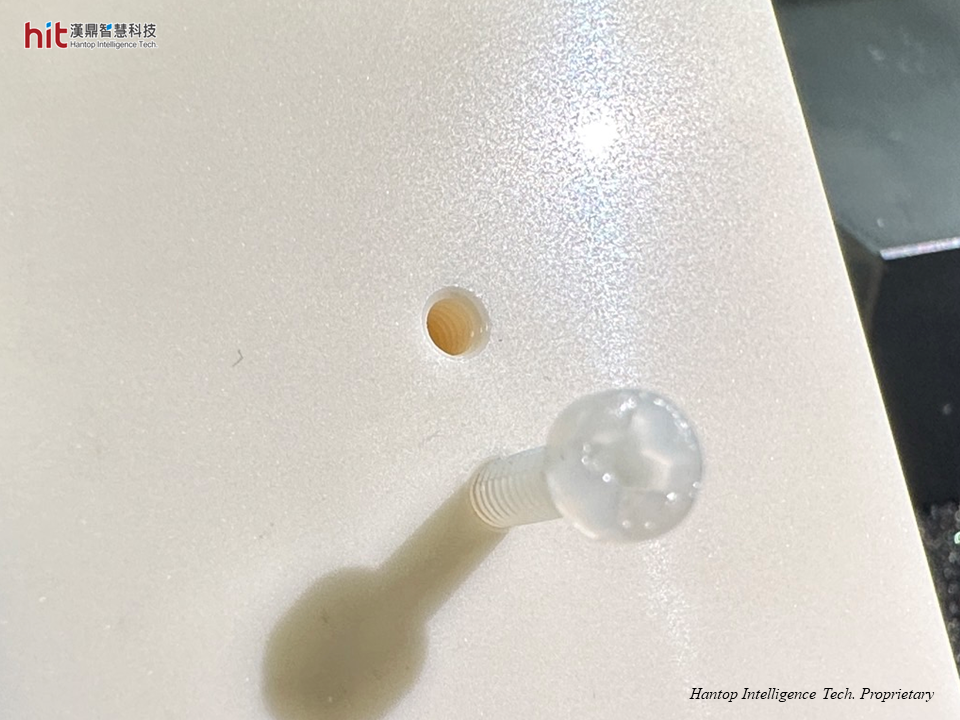

(Figure 10. HIT ultrasonic-assisted machining of aluminum oxide ceramic M2 internal threading)

Ceramic electrostatic chucks (E-chucks), using high-density porous ceramic layers, are critical components in various semiconductor manufacturing processes. These products ensure even distribution of adhesive forces during wafer cutting process. High-precision machining is required to meet the high-quality standards for micro-drilling and small internal threading features on E-chucks.

Common materials for E-chucks, such as aluminum oxide (Al2O3) ceramic, exhibit good chemical resistance and thermal stability, making them widely used in semiconductor manufacturing processes. However, when machining extremely small internal threads on aluminum oxide ceramic materials, conventional machining techniques face significant cutting forces, which accelerates tool wear and eventually damages the small internal threads feature.

💡 Learn more about HIT Ultrasonic-assisted Machining of Al2O3 (Aluminum Oxide) Ceramic M2 Internal Threading: 8x higher machining efficiency, 6x longer tool life

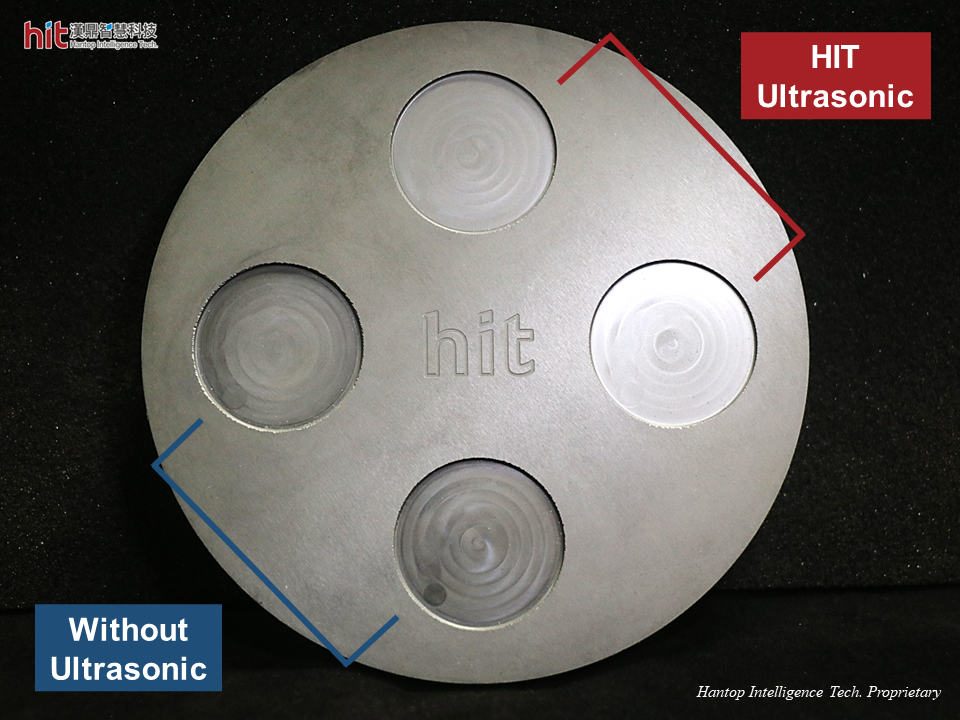

(Figure 11. HIT ultrasonic-assisted grinding of SiC silicon carbide helical/circular ramping)

Within the MOCVD process reactor chamber, SiC (silicon carbide) susceptors/carriers play a crucial role in supporting the substrates. The susceptors absorb thermal energy help with film growth. Consequently, the product quality of susceptors will have direct influecne on the quality of semiconductor epitaxial layers.

However, the high hardness of SiC and poor dust removal process can lead to significant blockage of grinding tools with ceramic dust during (helical) circular ramping. This will increase grinding forces and tool wear, which negatively affect the surface roughness of workpiece, potentially impacting overall product yield in wafer manufacturing process.

💡 Learn more about HIT Ultrasonic-assisted Grinding of SiC (Silicon Carbide) (Helical) Circular Ramping: 72% lower surface roughness, prevention of ceramic dust accumulation on the tool

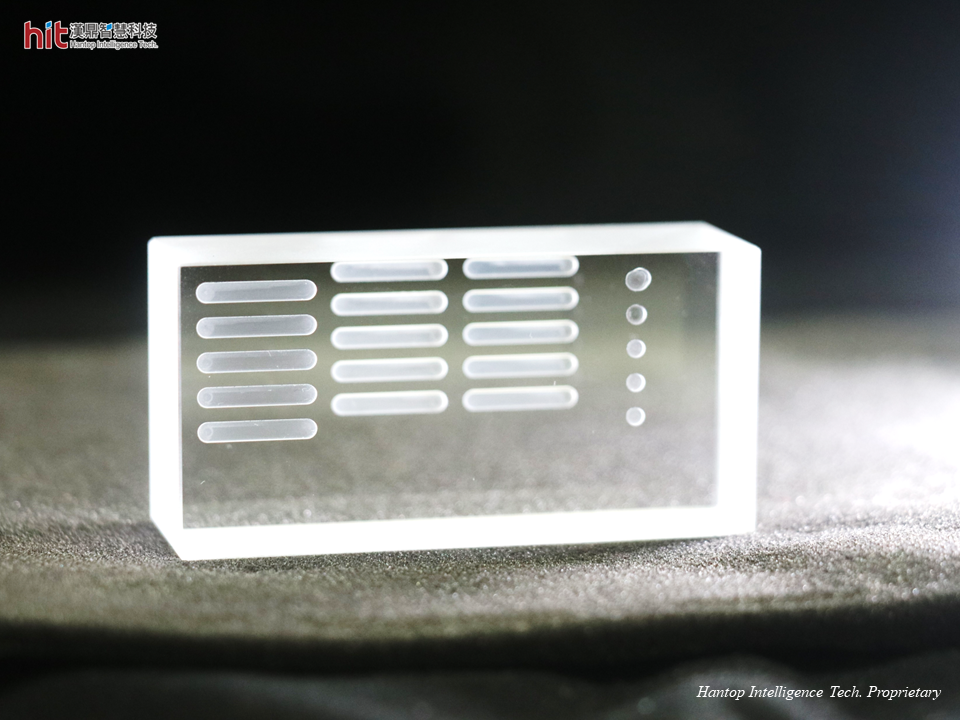

(Figure 12. HIT ultrasonic-assisted grinding of quartz glass micro-channel trochoidal machining)

Quartz glass microfluidic devices used in semiconductor process experiments or testing help reduce energy consumption and experimental costs.

However, for hard and brittle materials like quartz glass, excessive grinding forces during processing can result in massive edge-cracks on the workpiece, leading to turbulent flows in the micro-channel systems. As a result, post-processing through etching to remove the edge-cracks becomes necessary. The larger the edge-cracks, the longer the etching process, resulting in increased time and energy consumption.

💡 Learn more about HIT Ultrasonic-assisted Grinding of Quartz Glass Micro-channel Trochoidal Machining: less manufacturing steps, 2x smaller edge-cracks

-

Hantop Intelligence Tech.

✨Solution Provider of Advanced-Material Machining Technology & Smart Automation Modules✨

☎️ +886-4-2285-0838

📧 sales@hit-tw.com

To improve the machining efficiency, workpiece quality, and tool life, by following the trend of ESG, feel free to CONTACT US.