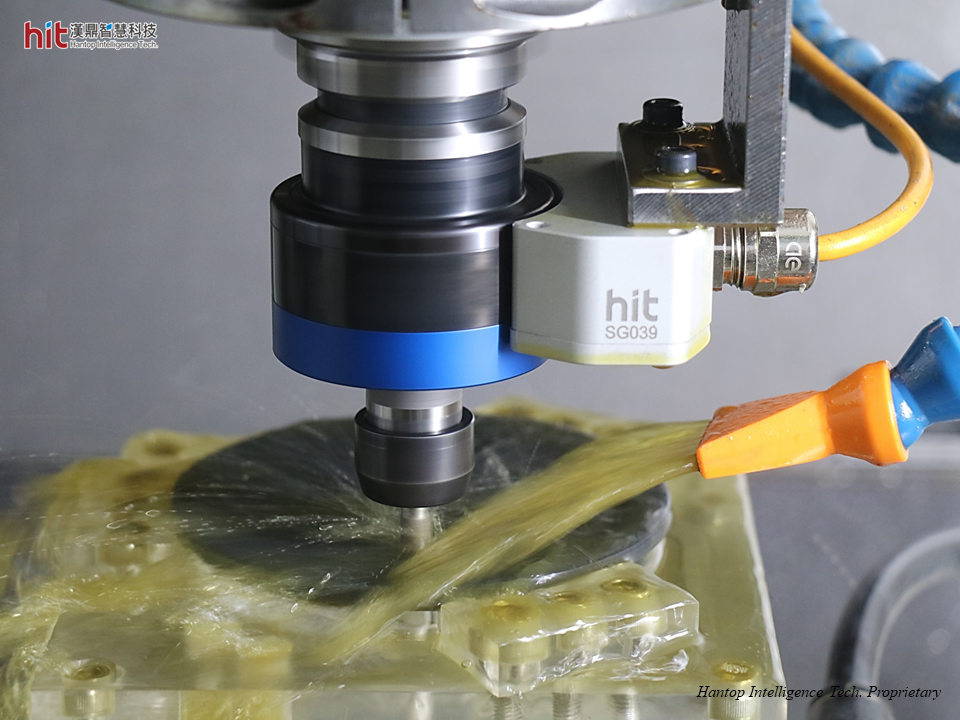

(Figure 1. HIT BT30 ultrasonic machining module was used on (helical) circular ramping of silicon carbide SiC)

(Figure 2. HIT ultrasonic-assisted (helical) circular ramping of silicon carbide SiC in the making of wafer susceptors)

HIT's Goal in (Helical) Circular Ramping of SiC (Silicon Carbide)

Through the assistance of HIT ultrasonic-assisted machining technology, the goal is to improve the surface roughness of workpiece, while reduce tool wear in (helical) circular ramping of SiC (Silicon Carbide) ceramic.

Ultrasonic-Assisted (Helical) Circular Ramping of SiC (Silicon Carbide) Machining Results

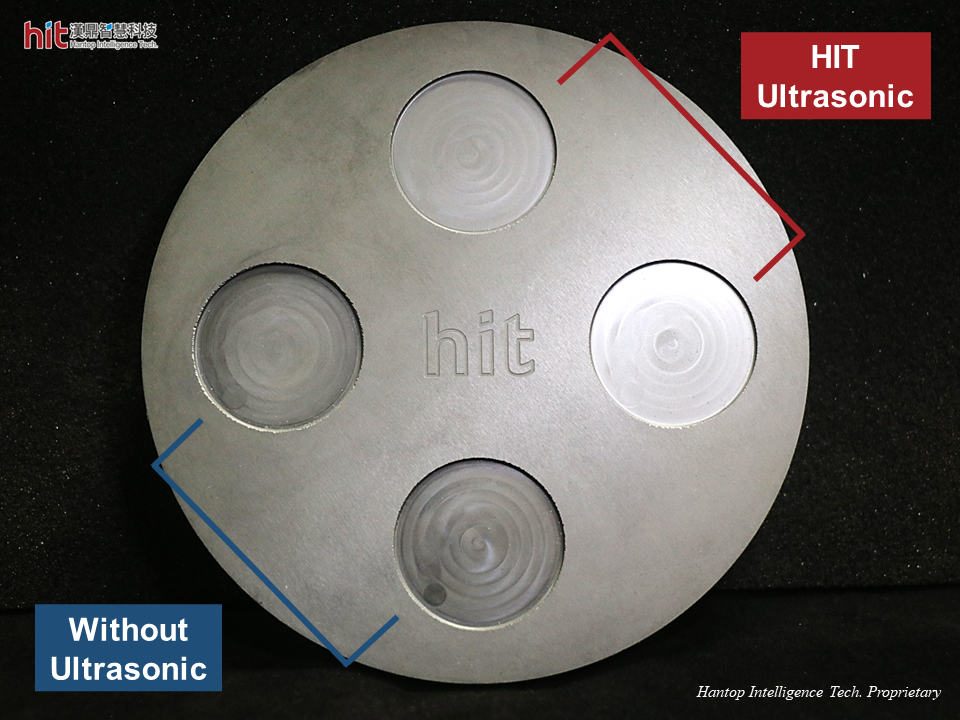

SiC (Silicon Carbide) Ceramic (Helical) Circular Ramping: Workpiece Quality

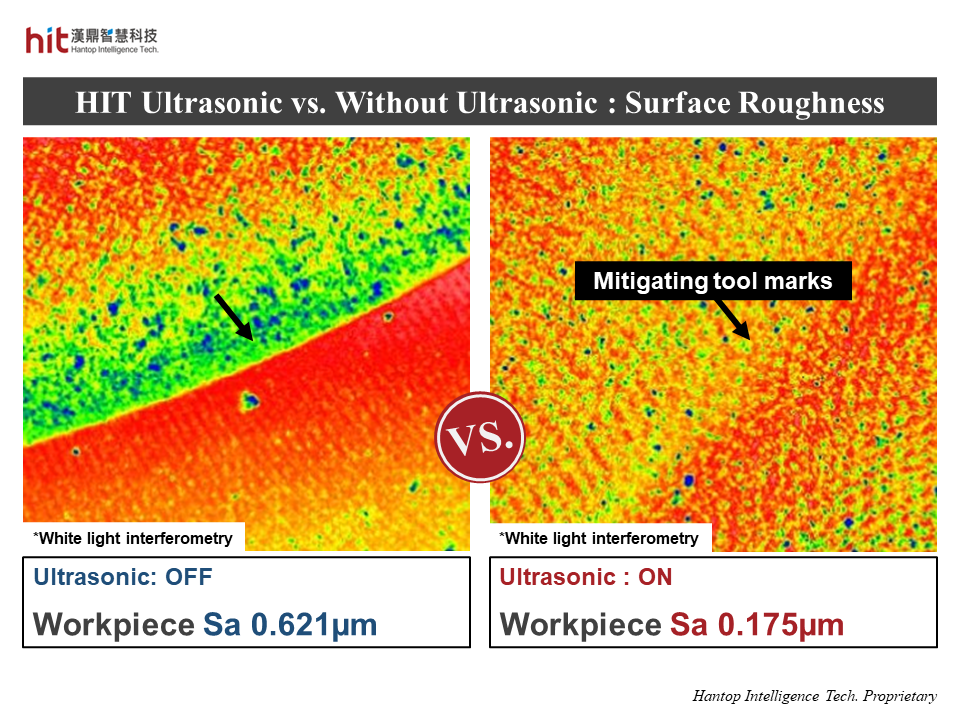

(Figure 3. HIT ultrasonic-assisted (helical) circular ramping of silicon carbide SiC greatly improved the surface roughness of workpiece with mitigating tool marks)

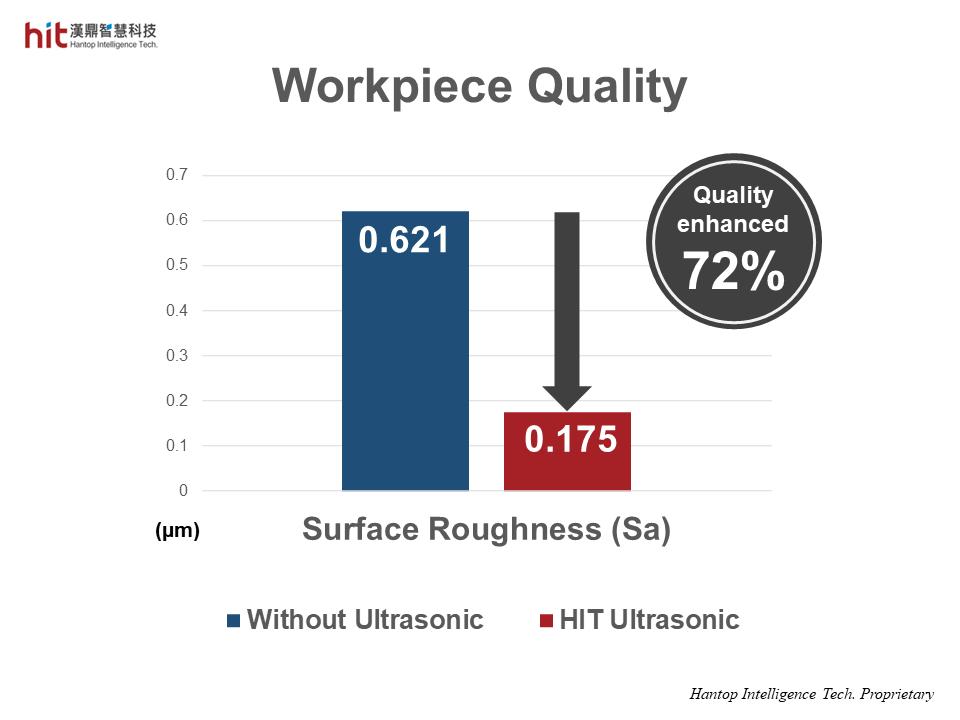

- With HIT ultrasonic, the high frequency micro-vibration helped reduce grinding forces. Thie resulted in great improvement in the surface roughness (Sa) of workpiece and mitigation of tool marks. The workpiece quality was enhanced by 72%.

- Ultrasonic-assisted machining technology in rough grinding process helped improve surface roughness and tool marks. This allowed for reduction in post-process time, which also increased machining efficiency.

(Figure 4. HIT ultrasonic-assisted (helical) circular ramping of silicon carbide SiC helped enhance workpiece quality by 72% with improved surface roughness)

SiC (Silicon Carbide) Ceramic (Helical) Circular Ramping: Tool Life

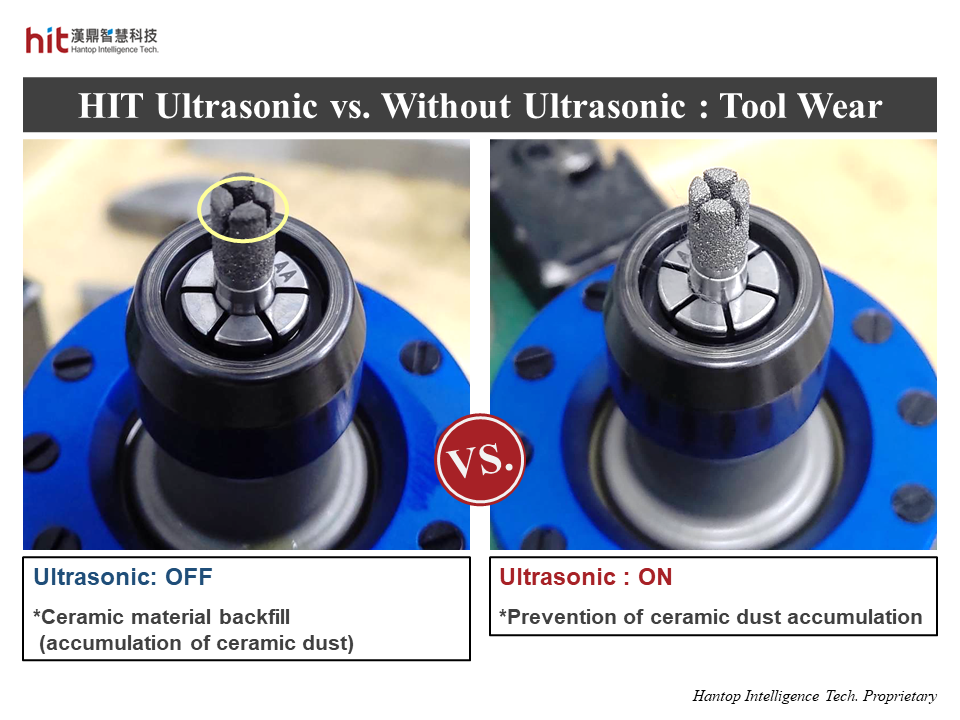

(Figure 5. HIT ultrasonic-assisted (helical) circular ramping of silicon carbide brought better particle flushing, preventing the tool from ceramic dust accumulation)

- With HIT ultrasonic, it provided the tool with high frequency micro-vibration in Z-axis direction. During the grinding process, the tool constantly lifting from workpiece brought easier inflow of cutting fluid. This helped with better particle flushing, which prevented the grinding tool from ceramic dust accumulation.

- Much less and slower accumulation of ceramic dust on the grinding tool helped reduce grinding forces. This not only resulted in less tool wear, but also higher surface quality.

HIT Ultrasonic Machining Technology on (Helical) Circular Ramping of SiC (Silicon Carbide) Achievements

📈 Quality - surface roughness (Sa) improved by 72% in rough grinding

⚙️ Tool Life - better particle flushing