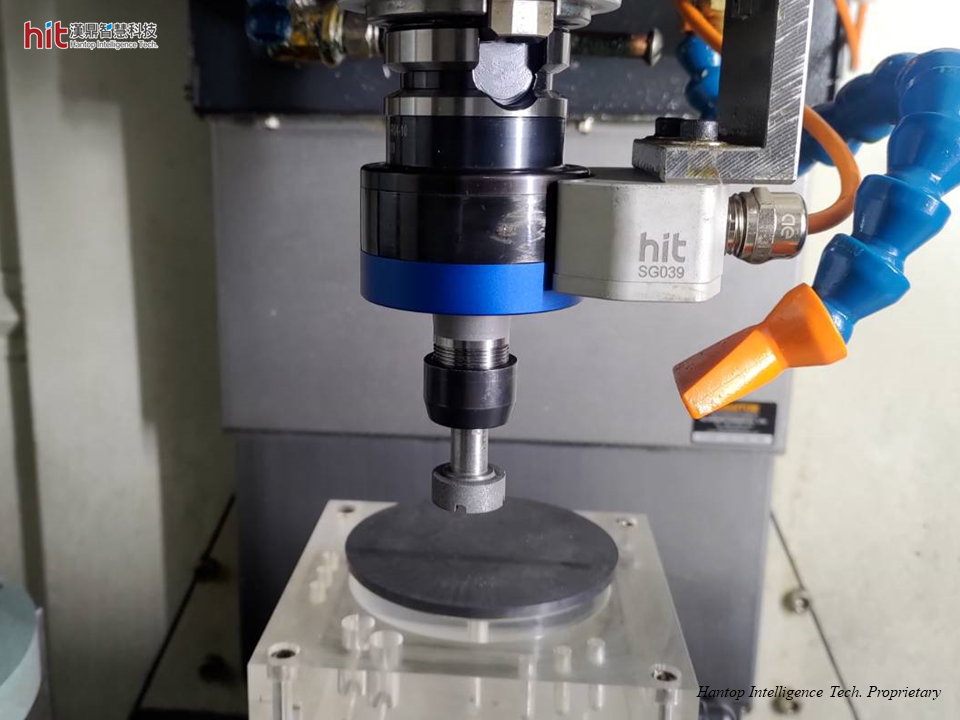

(Figure 1. HIT BT30 ultrasonic machining module was used on the machining of silicon carbide SiC grinding)

HIT's Goal in Grinding SiC (Silicon Carbide)

Through the assistance of HIT ultrasonic-assisted machining technology, the goal is to reduce the total process time and tool wear, while maintaining great workpiece quality in the machining of SiC (Silicon Carbide) ceramic grinding.

Ultrasonic-Assisted Grinding SiC (Silicon Carbide) Machining Results

SiC (Silicon Carbide) Grinding: Machining Efficiency

(Figure 2. HIT ultrasonic-assisted grinding silicon carbide SiC ceramic can achieve 2 times shorter total process time, due to the fact that there was no need for tool dressing during the process)

- With HIT ultrasonic, the high frequency micro-vibration helped with easier chip removal and better particle flushing. The grinding tool constantly lifting from workpiece allowed cutting fluid to flush away cutting heat and ceramic particles. This effectively prevented pores (between abrasives of the grinding tool from being filled with cumulative ceramic dust. As a result, there was no need for tool dressing during the entire grinding process.

- (Under the same machining parameters) Without ultrasonic, the grinding tool was constantly in contact with workpiece. This resulted in the tool re-grinding irremovable ceramic particles as well as pores being filled with cumulative ceramic dust. The tool would then need tool dressing due to decreased grinding ability. As a result, there were 4 times of tool dressing during the entire grinding process.

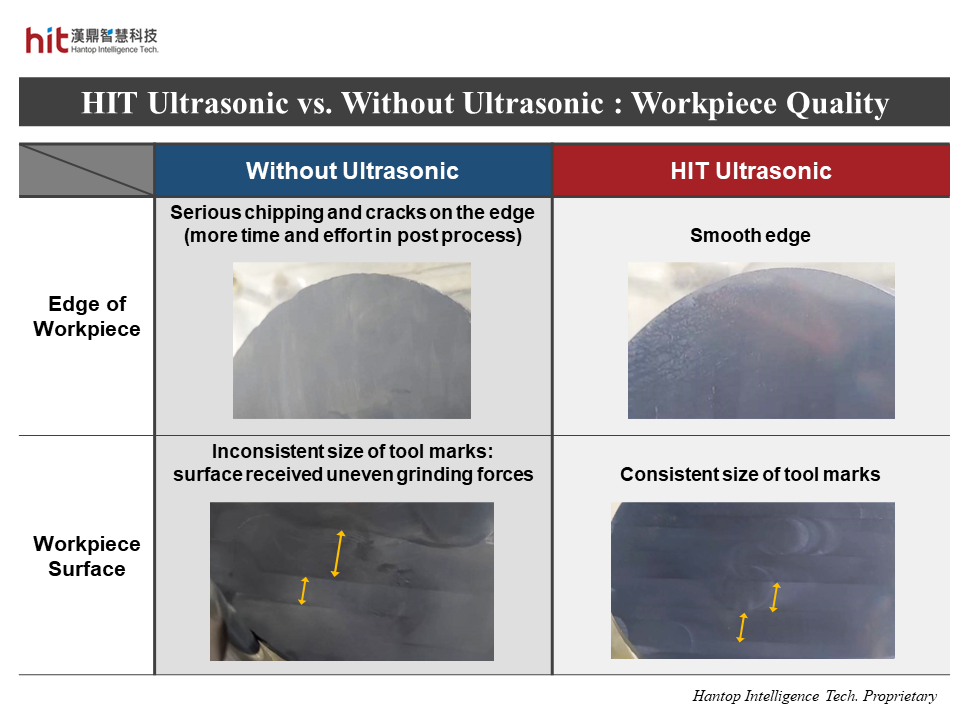

SiC (Silicon Carbide) Grinding: Workpiece Quality

(Figure 3. HIT ultrasonic-assisted grinding silicon carbide SiC ceramic can achieve workpiece with smooth edge without serious chipping or edge-cracks)

- With HIT ultrasonic, the high frequency micro-vibration helped with easier chip removal and better ceramic particle flushing. This effectively prevented pores (between abrasives) of the grinding tool from being filled with cumulative ceramic dust. The lowered and stable grinding forces helped reduce chipping or cracks on the edge of workpiece with consistent size of tool marks on the surface.

- (Under the same machining parameters) Without ultrasonic, the irremovable ceramic particles along with pores filled with cumulative ceramic dust caused quick loss in tool's grinding ability. The inconsistent size of tool marks on the surface of workpiece also showed unstable and uneven grinding forces, which resulted in not only serious tool wear but also workpiece damage (chipping and edge-cracks).

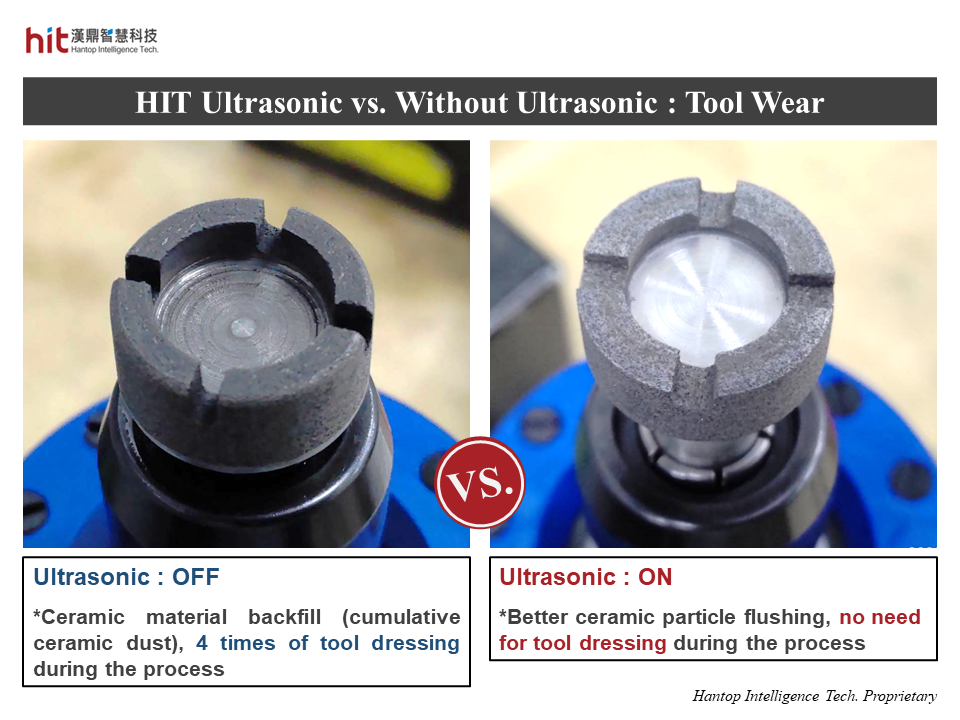

SiC (Silicon Carbide) Grinding: Tool Life

(Figure 4. HIT ultrasonic-assisted grinding silicon carbide SiC ceramic can achieve better ceramic particle flushing and without the need for tool dressing during the process)

- With HIT ultrasonic, the high frequency micro-vibration helped with better ceramic particle flushing. When the abrasive grains on the grinding tool became blunt after grinding, the grinding force would increase. Thus, it generated the self-sharpening mechanism. It made the worn-out abrasive grits fall off, and then the new diamond grits would come out to continue grinding. Since there was no need for tool dressing, the total tool wear only came from the grinding process.

- (Under the same machining parameters) Without ultrasonic, the irremovable ceramic particles along with pores filled with cumulative ceramic dust caused quick loss in tool's grinding ability. The accumulation of ceramic dust was too fast for the self-sharpening mechanism to restore the tool's grinding ability. As a result, there were 4 times of tool dressing during the grinding process, which caused even more tool wear.

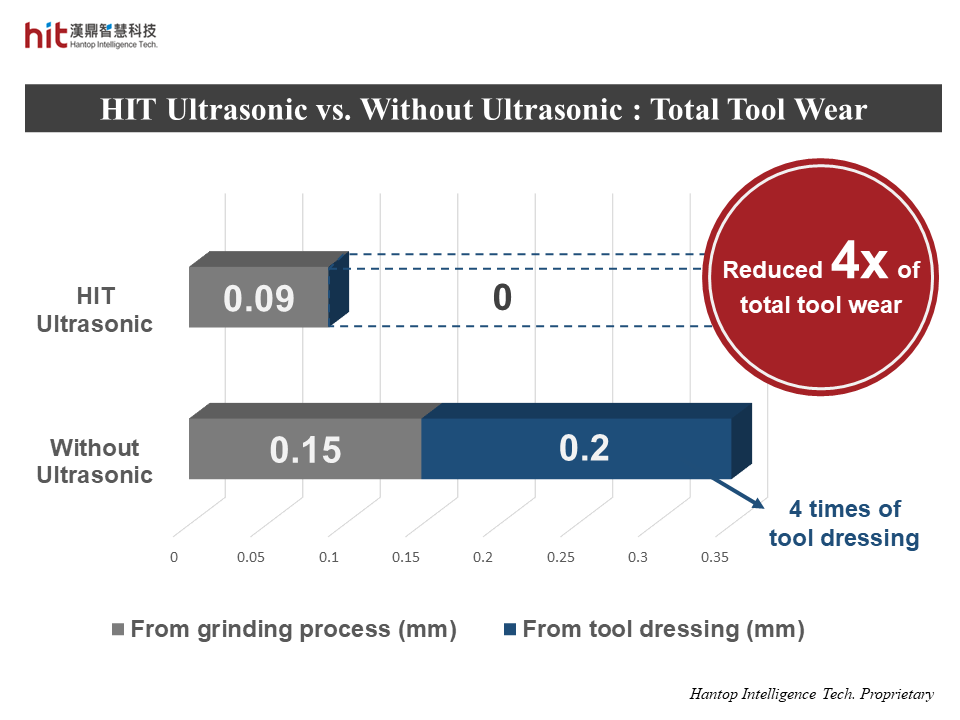

(Figure 5. HIT ultrasonic-assisted grinding silicon carbide SiC ceramic can greatly reduce tool wear and achieve 4 times longer tool life)

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - 2x shorter total process time

📈 Quality - no serious chipping or edge-cracks

⚙️ Tool Life - improved 4x