HIT Exhibition | TIMTOS 2025 - Taipei International Machine Tool Show

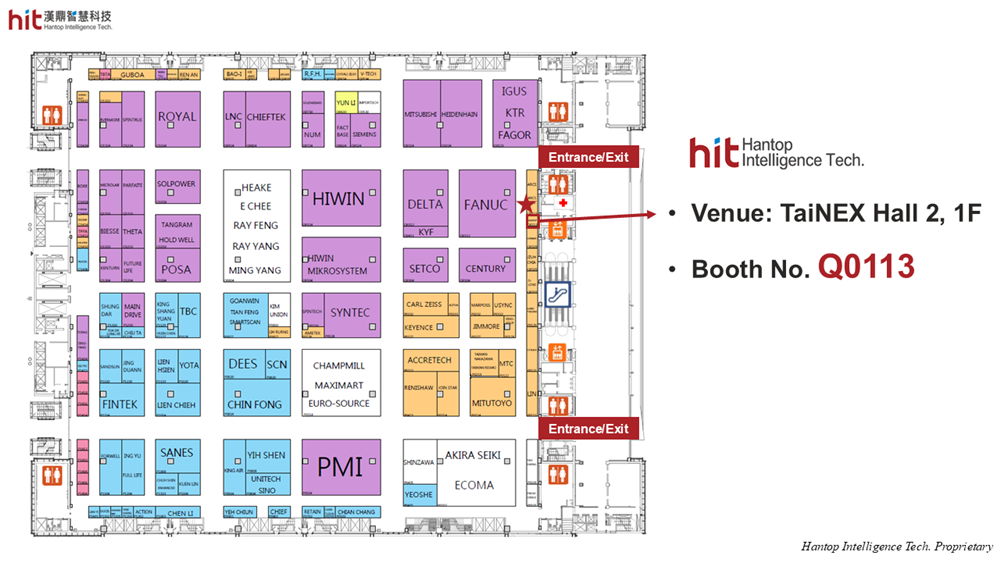

📍 Hantop Intelligence Tech. @ TIMTOS 2025

📅 Date: March 3rd (Mon.) ~ 8th (Sat.)

🕑 Time: 10:00 AM ~ 6:00 PM (Last day till 5:00 PM)

👣 Venue: Taipei Nangang Exhibition Center (TaiNEX), Hall 2, 1st Floor

🎪 HIT Booth: Inspection & Measuring Instruments Area No. Q0113

🔗 TIMTOS FREE Pre-Registration

(Figure 1. TIMTOS 2025 - HIT at Taipei Nangang Exhibition Center Hall 2, 1st Floor - Inspection and Measuring Instruments Area, Booth Q0113)

This year marks the 30th edition of the Taipei International Machine Tool Show (TIMTOS 2025), which will be held from March 3 to 8, 2025. This year's exhibition is centered around the theme "Integrate to Innovate," emphasizing the integration of machine tool processing applications to drive innovation. The exhibition will also focus on three main themes: AI and robotics, future smart manufacturing, and green sustainability, bringing more intelligent solutions to the industry.

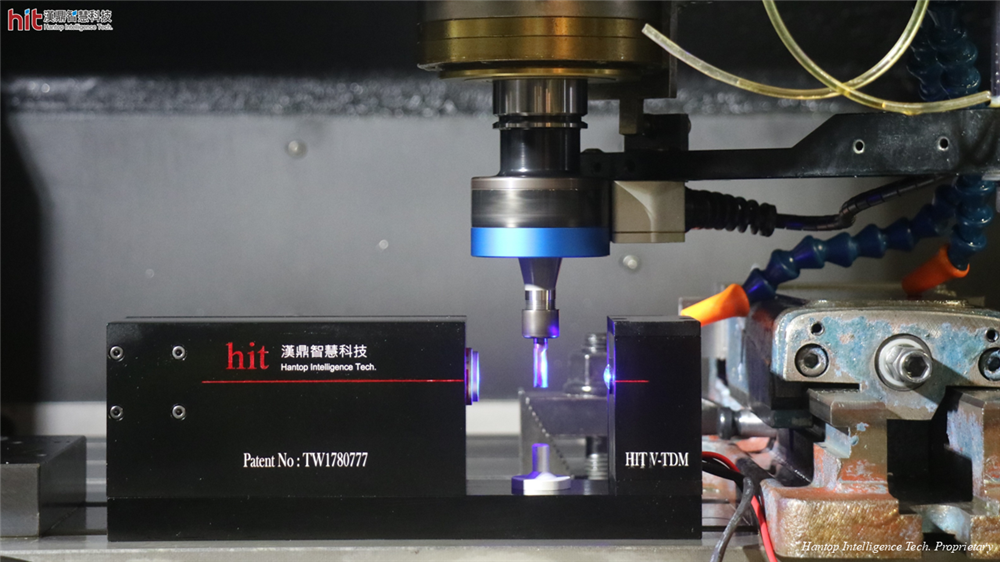

Hantop Intelligence Tech. (HIT) will be exhibiting at Nangang Exhibition Center Hall 2, 1st Floor - Inspection and Measuring Instrument Area, Booth Q0113. At this event, HIT will showcase its ultrasonic-related product, the CNC On-Machine Visual Tool Dynamic Measurement Instrument. This product has two major highlights: 1) it helps confirm the vibration mode of the tool when ultrasonic is activated and outputs 2D visual measurement data of the ultrasonic amplitude; 2) it can output 2D visual measurement data of the tool's dynamic runout at high speeds (24,000 rpm).

🎙️AI Podcast: CNC On-Machine Visual Tool Dynamic Measurement Instrument

(Figure 2. HIT develops on-machine visual tool dynamic measurement instrument, capable of outputting 2D visual measurement data of ultrasonic amplitude and tool dynamic runout)

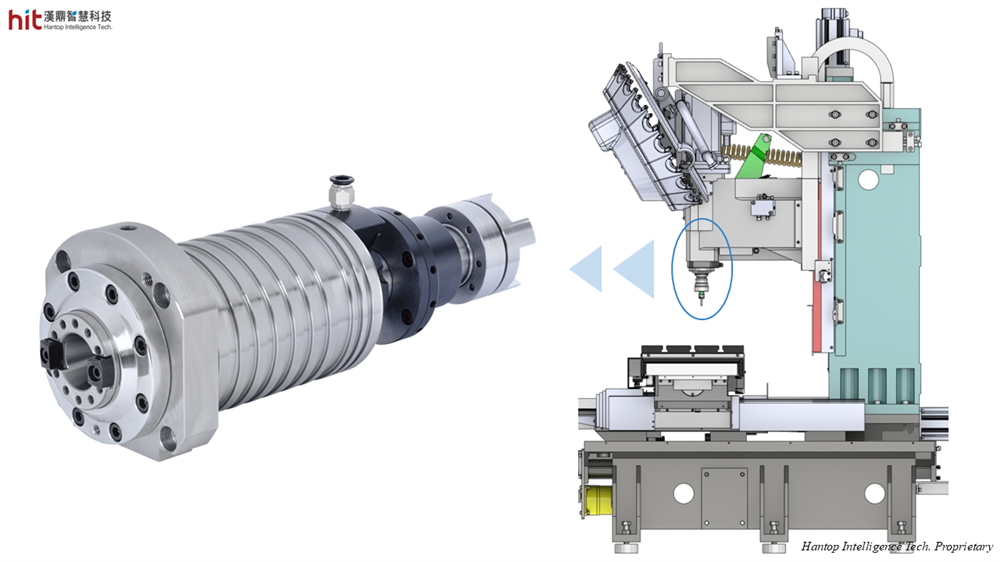

Additionally, HIT will present a new product: Non-contact Power Transmission Ultrasonic High-Speed Spindle - UTD30. HIT has successfully integrated a non-contact power transmission system into the spindle, enabling non-contact power to be transmitted to the high-speed rotating tool holder. This innovation allows traditional CNC machine tools to be rapidly upgraded into systems capable of processing advanced hard and brittle semiconductor materials, significantly enhancing the added value and marketability of CNC machine tools.

(Figure 3. HIT new product - non-contact power transmission ultrasonic high-speed spindle UTD30, integrating non-contact power transmission system into the spindle to help traditional CNC machines upgrade for semiconductor material processing)

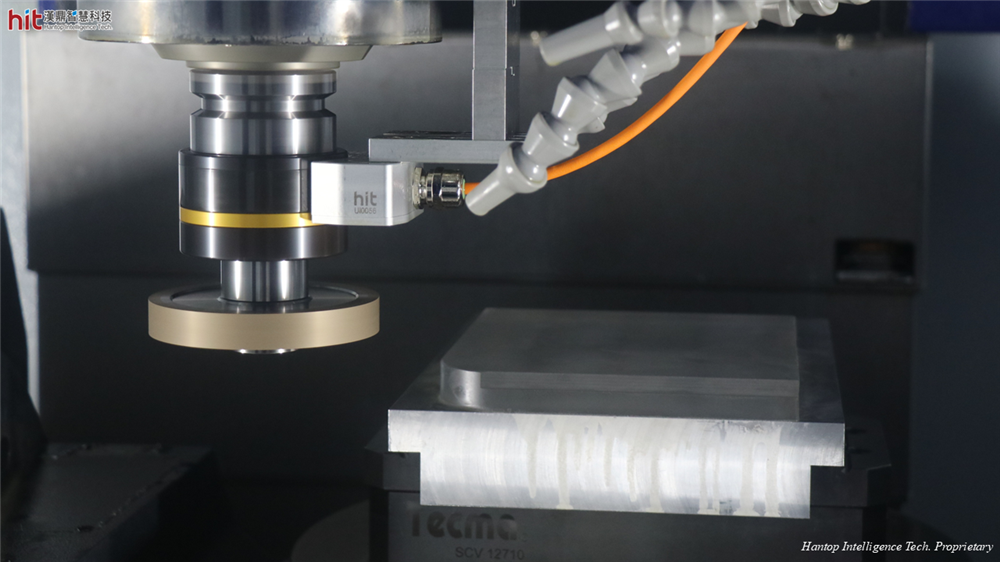

Another new product, the Ultrasonic Grinding Wheel Toolholder, along with its related applications, will also make its debut at this exhibition. HIT applies an ultrasonic high-frequency vibration-assisted machining mechanism, utilizing a threaded locking method in combination with specially formulated grinding wheels, offering a new solution for processing semiconductor equipment consumables such as SiC wafer susceptors and quartz rings. By increasing the Material Removal Rate (MRR), this innovation significantly enhances overall processing efficiency. Additionally, the ultrasonic high-frequency vibration mechanism helps effectively remove ceramic particles, reduces tool wear, and lowers production costs, all while ensuring high-quality workpieces.

🎙️AI Podcast: Ultrasonic Grinding Wheel Toolholder

(Figure 4. HIT new product - ultrasonic grinding wheel toolholder, providing a new processing solution for semiconductor equipment consumables, enhancing efficiency, reducing tool wear, and improving workpiece quality)

💡Get a First Look at Ultrasonic Grinding Wheel Toolholder Applications:

Another major highlight of this exhibition is HIT's main product, the Ultrasonic-assisted Machining Module, which introduces the latest optimized machining process case study: Profile Milling (Roughing) of STAVAX Mould Steel material. By using HIT's ultrasonic tool holder module to optimize the rough milling process under low-speed cutting conditions, the results achieved include: a 5.5x increase in overall machining efficiency, a 5x extension of tool life, and significant suppression of burr formation.

💡Learn more detailed information on the case study-Profile Milling (Roughing) of STAVAX Mould Steel

🎙️AI Podcast: Ultrasonic-assisted Profile Milling of STAVAX Mould Steel

⬇️⬇️Watch the Processing Video Now⬇️⬇️

💝We look forward to welcoming industry experts to visit our booth and join us in this grand event. We also encourage everyone to stay updated with the latest developments by following HIT’s official website for more news!

💡Learn more about Ultrasonic-assisted Machining Product Application Cases

-

Hantop Intelligence Tech.

Optimized Solution for Machining of Advanced-Material with Ultrasonic-Assisted Machining Module

Optimized Solution for Machining of Advanced-Material with Ultrasonic-Assisted Machining Module

+886-4-2285-0838

+886-4-2285-0838

sales@hit-tw.com

sales@hit-tw.com

To improve the machining efficiency, workpiece quality, and tool life, by following the trend of ESG, feel free to CONTACT US.