HIT's Goal in (Fine) Surface Grinding of Aluminum Oxide with D100-Grinding Wheel Toolholder

Through the assistance of HIT ultrasonic-assisted machining technology with the new product - Ultrasonic Grinding Wheel Toolholder, the goal is to enhance machining efficiency and workpiece quality.

Ultrasonic-Assisted (Fine) Surface Grinding of Aluminum Oxide with D100-Grinding Wheel Toolholder: Machining Results

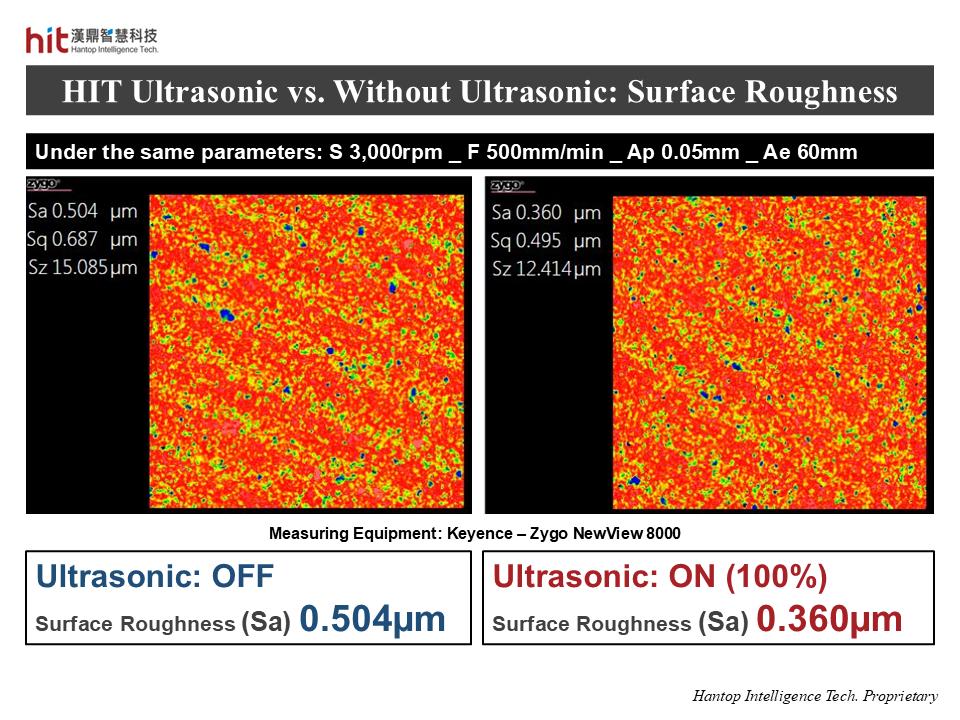

(Fine) Surface Grinding of Aluminum Oxide with D100-Grinding Wheel Toolholder: Workpiece Quality

(Figure 1. with HIT HBT-40 ultrasonic grinding wheel toolholder module, the surface roughness can be improved compared to that without ultrasonic)

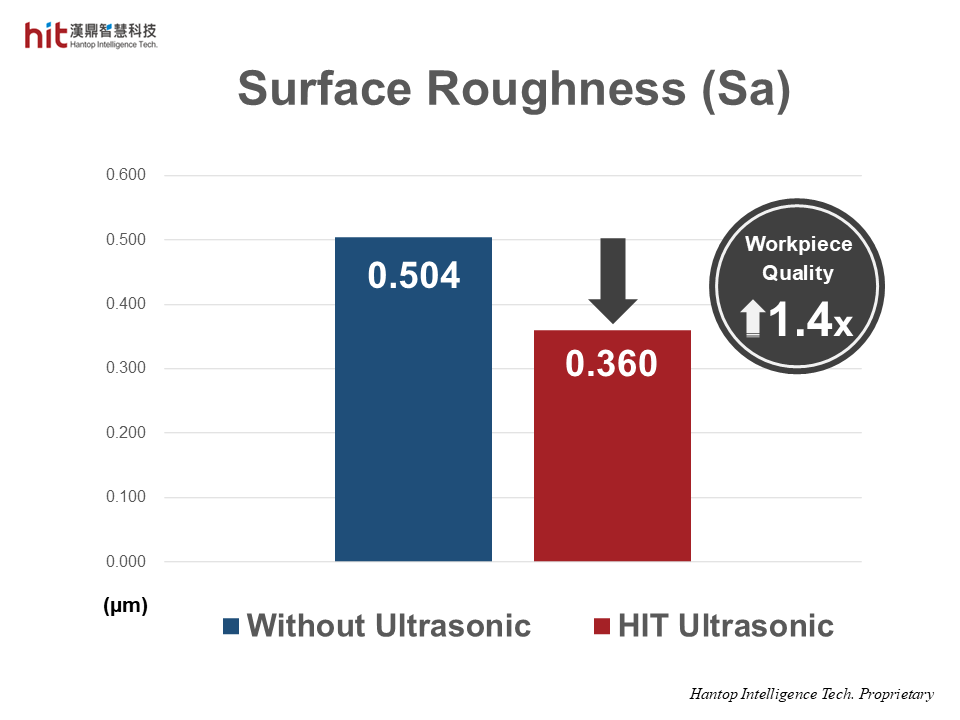

(Figure 2. with HIT HBT-40 ultrasonic grinding wheel toolholder module, the overall workpiece quality can be 1.4x better)

- To optimize the surface grinding (fine) process of aluminum oxide ceramic with HIT ultrasonic module, the high frequency micro-vibration helped reduce grinding force.

- Under the same machining parameters, the surface roughness can be improved with HIT ultrasonic, which brought 1.4x better overall workpiece quality.

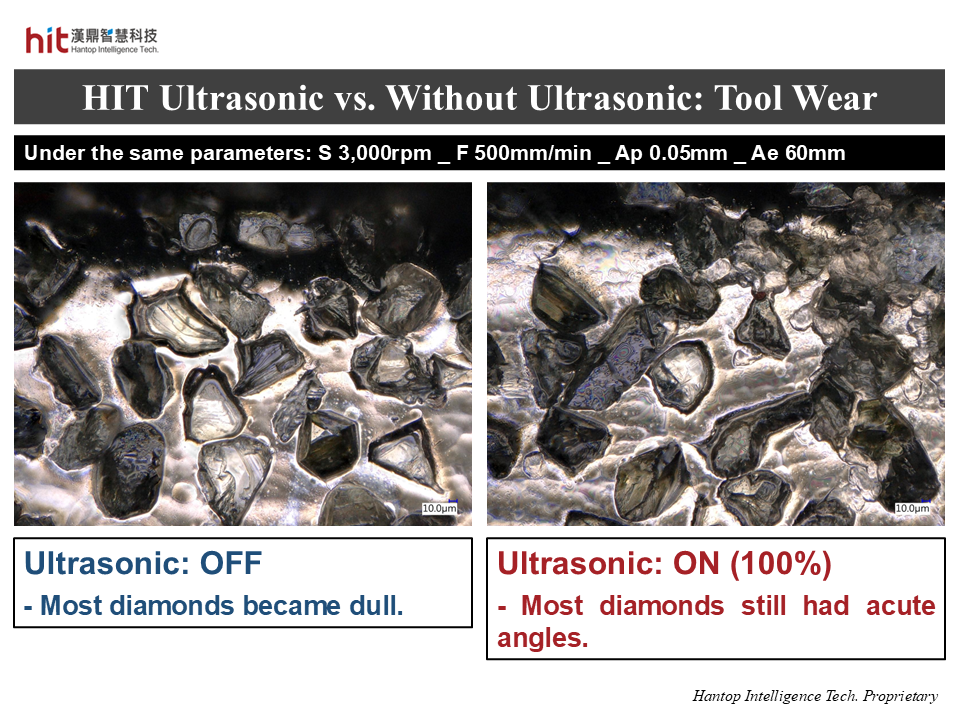

(Fine) Surface Grinding of Aluminum Oxide with D100-Grinding Wheel Toolholder: Tool Life

(Figure 3. with HIT HBT-40 ultrasonic grinding wheel toolholder module, it helped the grinding wheel maintain great grinding ability with less tool wear)

- To optimize the surface grinding (fine) process of aluminum oxide ceramic with HIT ultrasonic module, the high frequency micro-vibration and better ceramic particles flushing helped reduce grinding force.

- Under the same machining parameters, tool wear can be reduced compared to that without ultrasonic. Most of the diamonds on the wheel surface still had acute angles (stable grinding ability) after machining.

HIT Ultrasonic Machining Technology Achievements in (Fine) Surface Grinding of Aluminum Oxide with D100-Grinding Wheel Toolholder

(with HIT HBT40 Ultrasonic Grinding Wheel Toolholder)

📈 Surface Quality - 1.4x better, with improved surface roughness (Sa)

⚙️ Reduced tool wear, remaining fine grinding ability