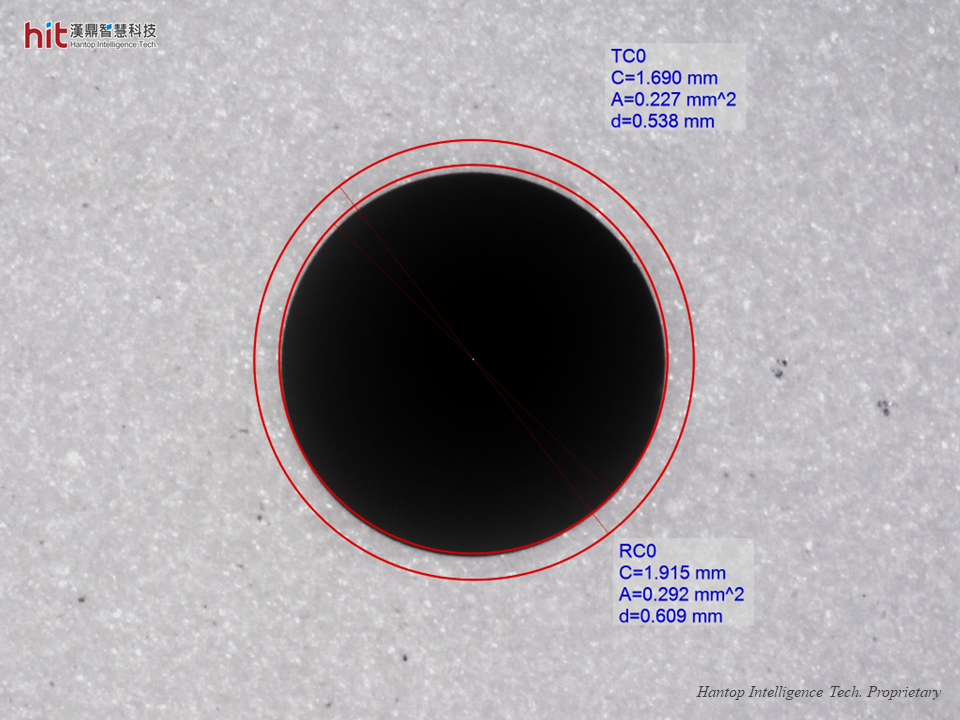

(Figure 1. hole quality of HIT ultrasonic-assisted G81 micro-drilling of aluminum oxide ceramic)

HIT's Goal in Aluminum Oxide (Al2O3) Ceramic G81 Micro-Drilling

The goal is to enhance the machining efficiency, while maintaining great hole quality and increasing tool life.

Ultrasonic-Assisted G81 Micro-Drilling of Aluminum Oxide (Al2O3) Ceramic Results

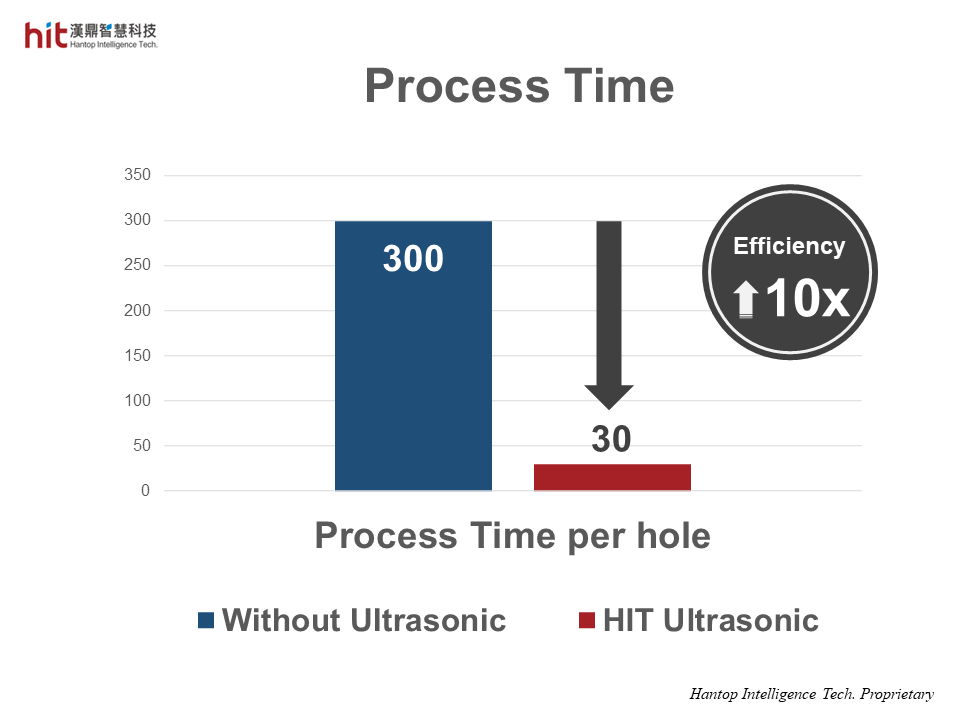

Aluminum Oxide (Al2O3) Ceramic G81 Micro-Drilling : Machining Efficiency

(Figure 2. the machining efficiency was 10x higher with HIT ultrasonic-assisted G81 micro-drilling of aluminum oxide ceramic)

*Original process & parameters: S 10,000rpm_F 3mm/min_Q 0.1mm_G83

- With HIT ultrasonic, the high frequency micro-vibration in Z-axis direction helped reduce cutting force.

- By using G81 as the main drilling process, feed rate can be further increased (from F 3mm/min to F 8mm/min, and then to F 10mm/min). Efficiency was 10x higher with well-maintained hole quality.

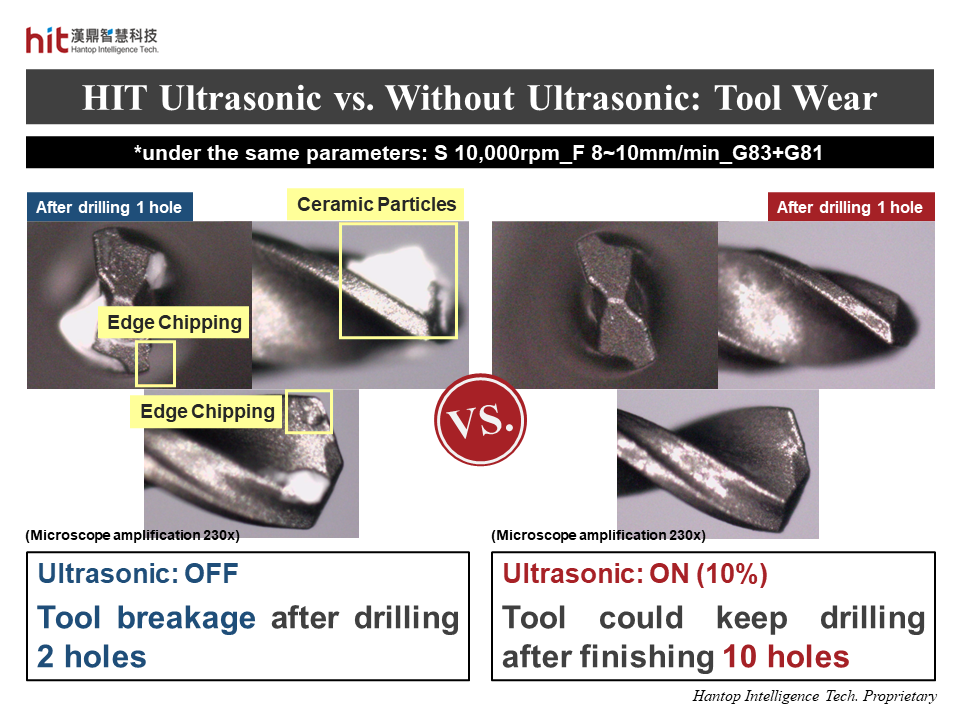

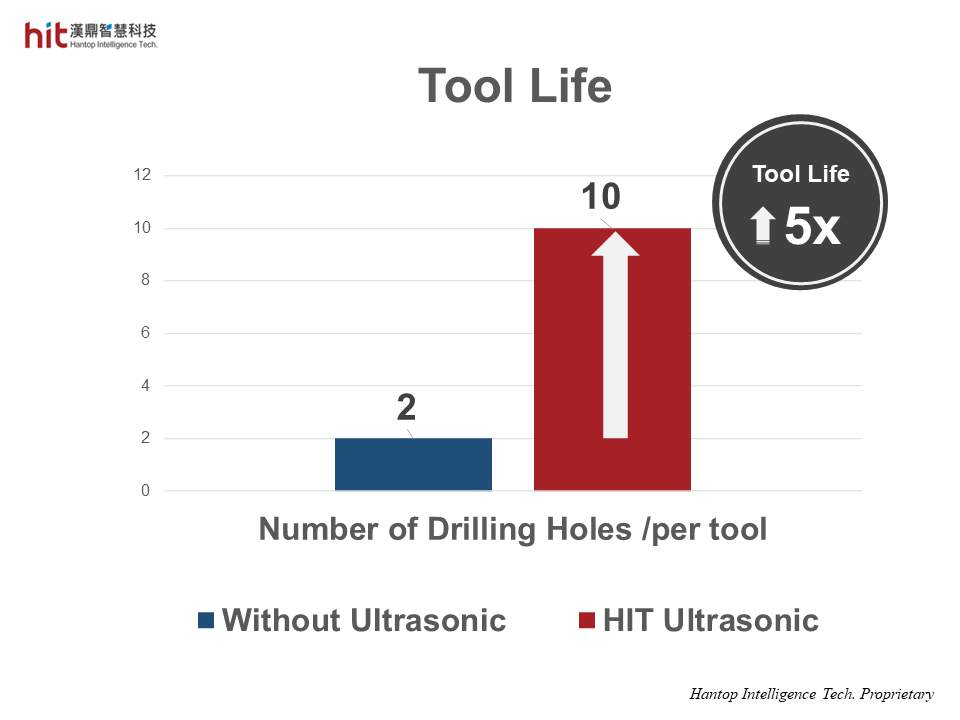

Aluminum Oxide (Al2O3) Ceramic G81 Micro-Drilling : Tool Life

(Figure 3. HIT HSK-E40 ultrasonic machining module was used on aluminum oxide ceramic G81 micro-drilling, which helped reduce tool wear)

(Figure 4. the tool life was 5x longer with HIT ultrasonic-assisted G81 micro-drilling of aluminum oxide ceramic)

- Ultrasonic-assisted machining mechanism allowed for easier evacuation of cutting chips (ceramic particles) under G81 process.

- Under the same machining parameters without ultrasonic, tool breakage happened after drilling 2 holes. With HIT ultrasonic, the tool could keep drilling after finishing 10 holes. Tool life was then 5x longer compared to that without ultrasonic.

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - 10x higher

📈 Hole Quality - well-maintained

⚙️ Tool Life - 5x longer