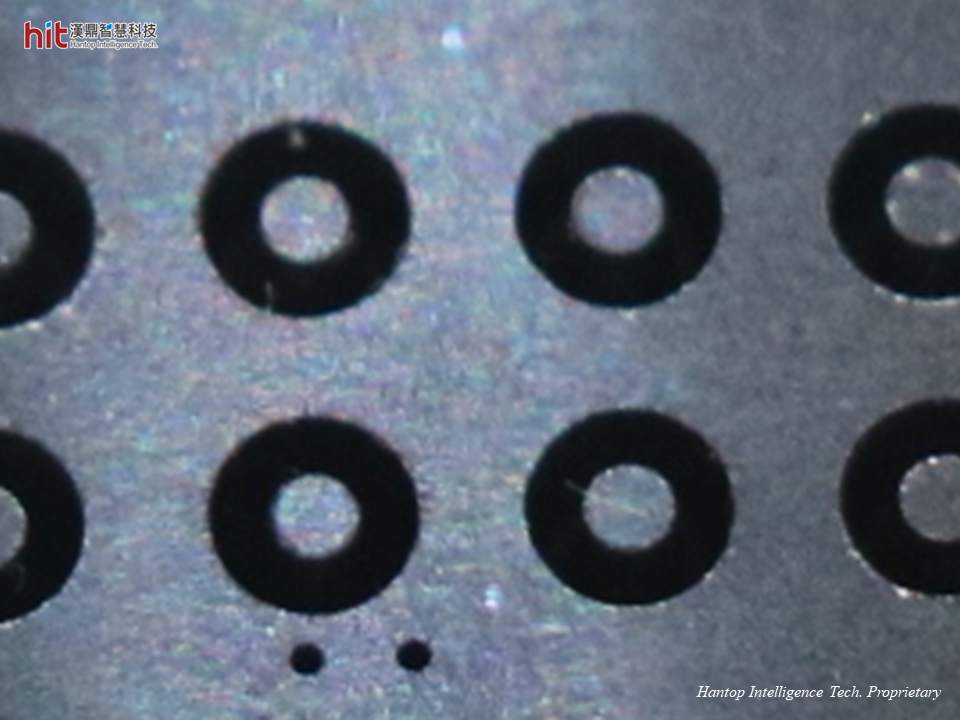

(Figure 1. SiC workpiece of HIT ultrasonic-assisted G81 drilling of silicon carbide)

HIT's Goal in G81 Drilling of SiC (Silicon Carbide)

The goal is to see how HIT ultrasonic-assisted machining technology can benefit the machining of G81 drilling on SiC (Silicon Carbide) in terms of tool life and hole quality.

Ultrasonic-Assisted G81 Drilling of SiC (Silicon Carbide): Machining Results

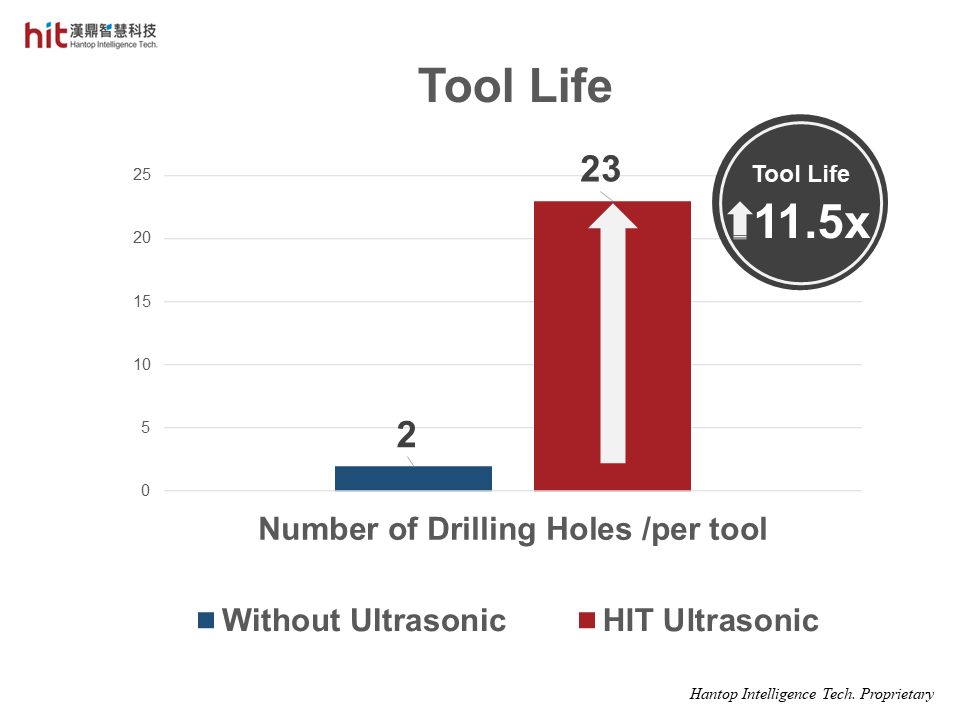

SiC (Silicon Carbide) G81 Drilling: Tool Life

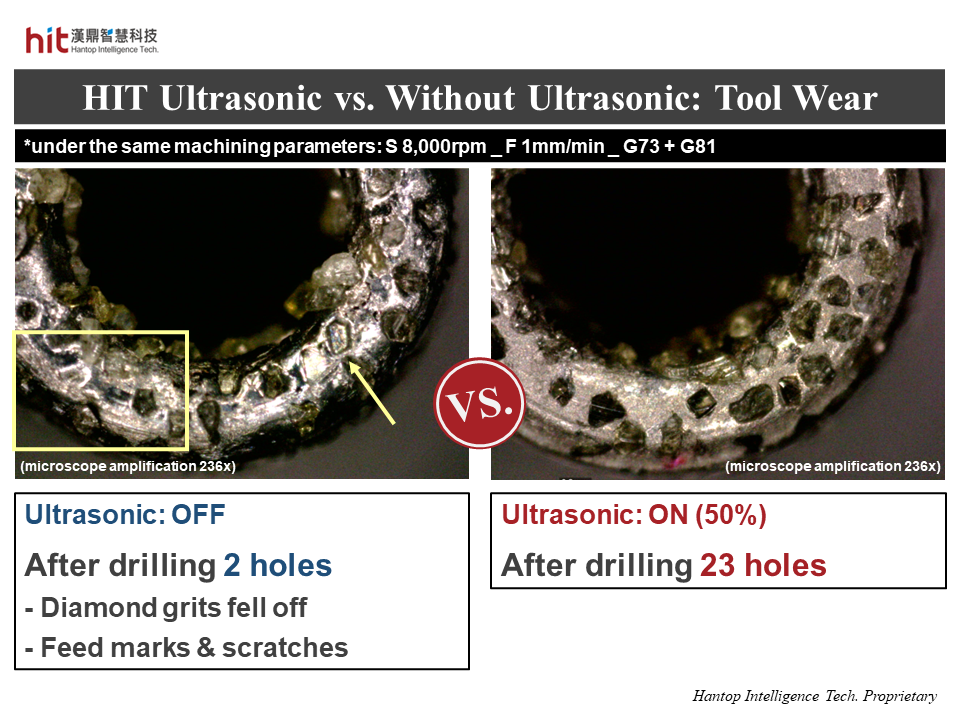

(Figure 2. HIT HSK-E40 ultrasonic machining module was used on silicon carbide SiC G81 drilling, which helped greatly reduce tool wear)

(Figure 3. the tool life was 11.5x longer with HIT ultrasonic-assisted G81 drilling of silicon carbide SiC)

*Original process & parameters suggested by tooling supplier: S 8,000rpm _ F 1mm/min _ Q 0.02mm _ G83

- With HIT ultrasonic, the high frequency micro-vibration in Z-axis direction helped reduce cutting force.

- The tool was not in constant contact with the workpiece, along with CTS (coolant through spindle) function, it helped remove the generated cutting heat.

- Tool life can thus be 11.5x longer under great hole quality.

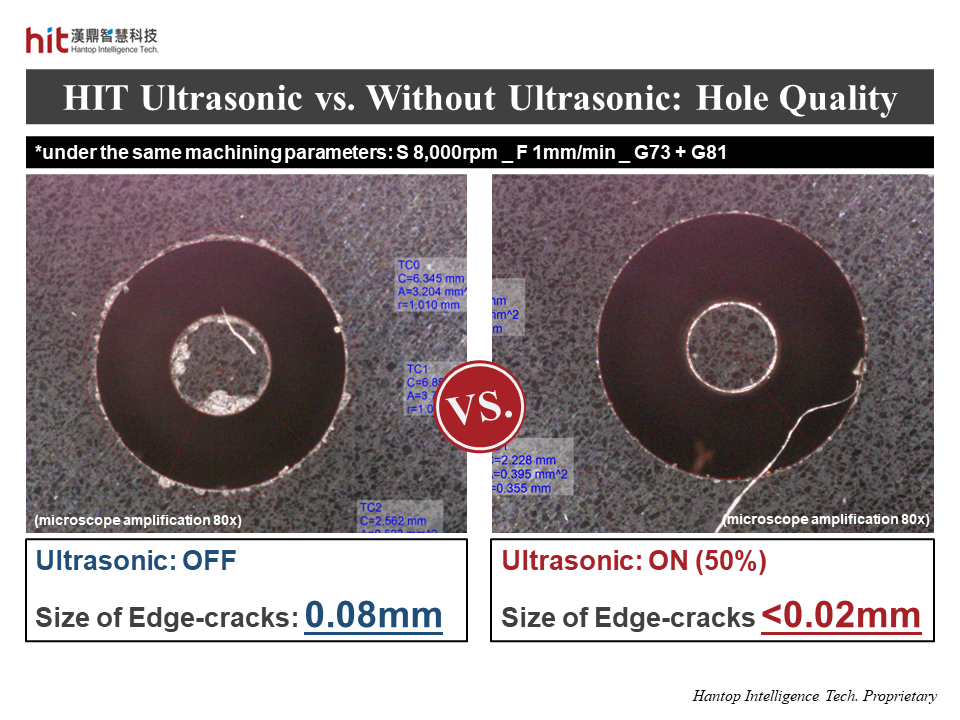

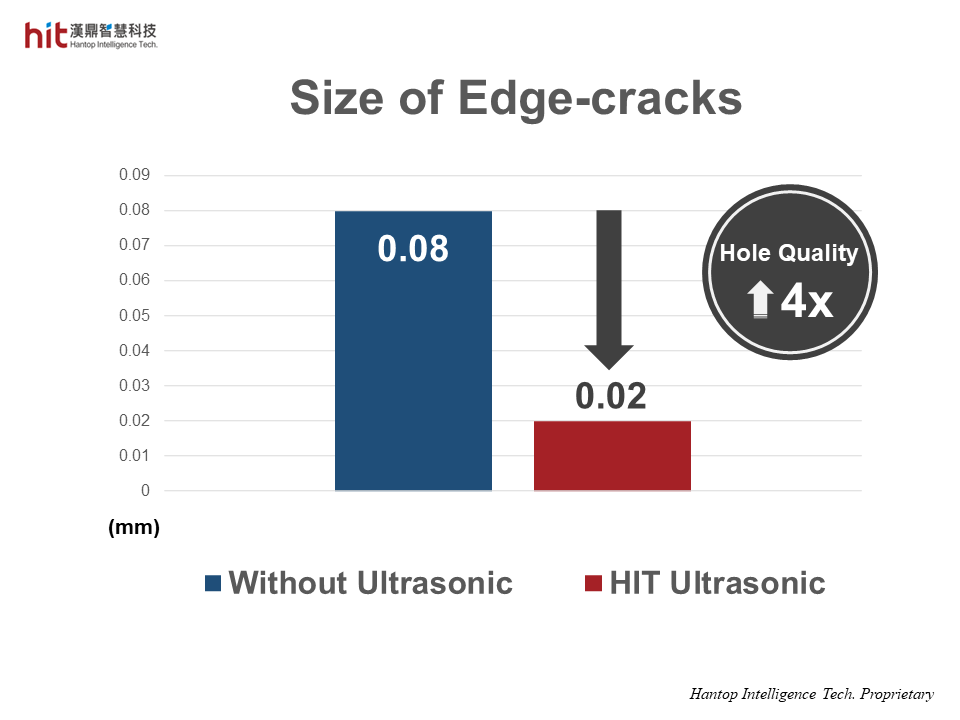

SiC (Silicon Carbide) Micro-Drilling : Hole Quality

(Figure 4. HIT HSK-E40 ultrasonic machining module was used on silicon carbide SiC G81 drilling, which had smaller size of edge-cracks)

(Figure 5. the hole quality was 4x better with HIT ultrasonic-assisted G81 drilling of silicon carbide SiC)

- Ultrasonic-assisted machining mechanism along with CTS allowed for better ceramic particle flushing under G81 process.

- The great reduction in cutting force and cutting heat contributed to less tool wear and longer tool life, which helped maintain good drilling hole quality.

HIT Ultrasonic Machining Technology Achievements

⚙️ Tool Life - 11.5x longer

📈 Hole Quality - 4x better, reduction in size of edge-cracks