(Figure 1. HIT HSK-E40 ultrasonic machining module was used on profile milling of Al6061 aluminum alloy)

HIT's Goal in Profile Milling (Micro-Conical Structure) of Aluminum Alloy (Al6061)

The goal is to do profile milling (micro-conical structure) of aluminum alloy with the torus milling cutter. With HIT ultrasonic, it was expected to mitigate the tool marks on the surface and to reduce tool wear.

Ultrasonic-Assisted Profile Milling (Micro-Conical Structure) of Aluminum Alloy (Al6061): Machining Results

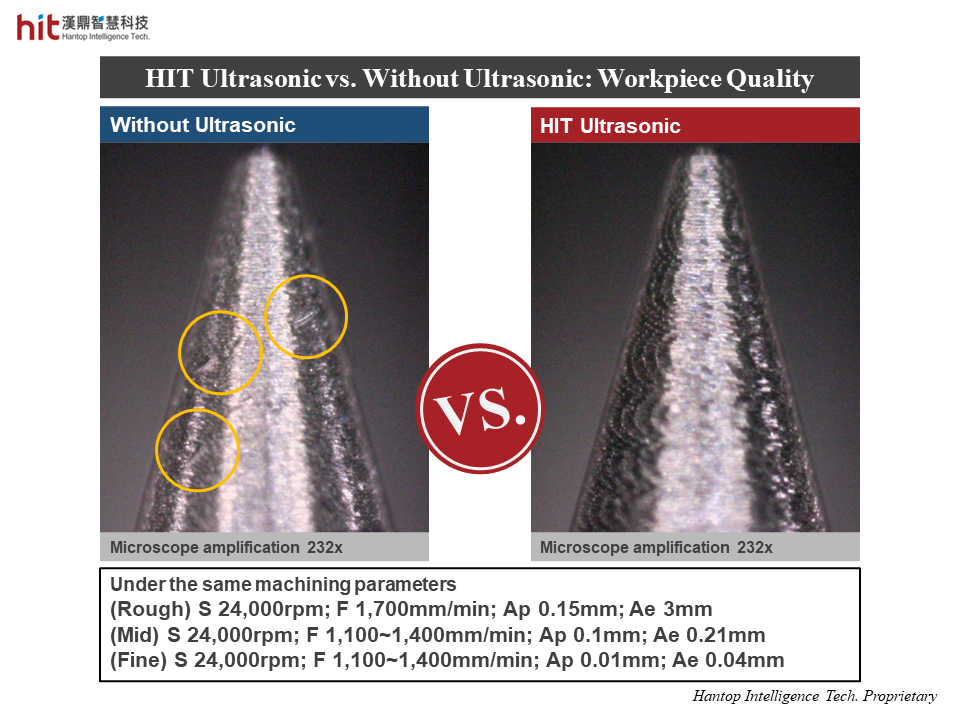

Aluminum Alloy (Al6061) Profile Milling (Micro-Conical Structure): Workpiece Quality

(Figure 2. HIT ultrasonic-assisted profile milling of Al6061 aluminum alloy achieved better surface quality)

- In conventional machining (without ultrasonic) of soft metal, usually there would be long and stringy chips due to material properties. This would cause BUE (Built-Up Edge) on the tool and lead to increasing cutting forces. BUE on the tool also resulted in obvious scratches left on the surface of workpiece.

- With HIT ultrasonic, the high frequency micro-vibration helped with better chip evacuation. The tool could cut off the material more easily, which helped prevent the increasing cutting forces. Surface of workpiece was smooth without defects, and the consistent marks showed the tool received uniform forces during machining.

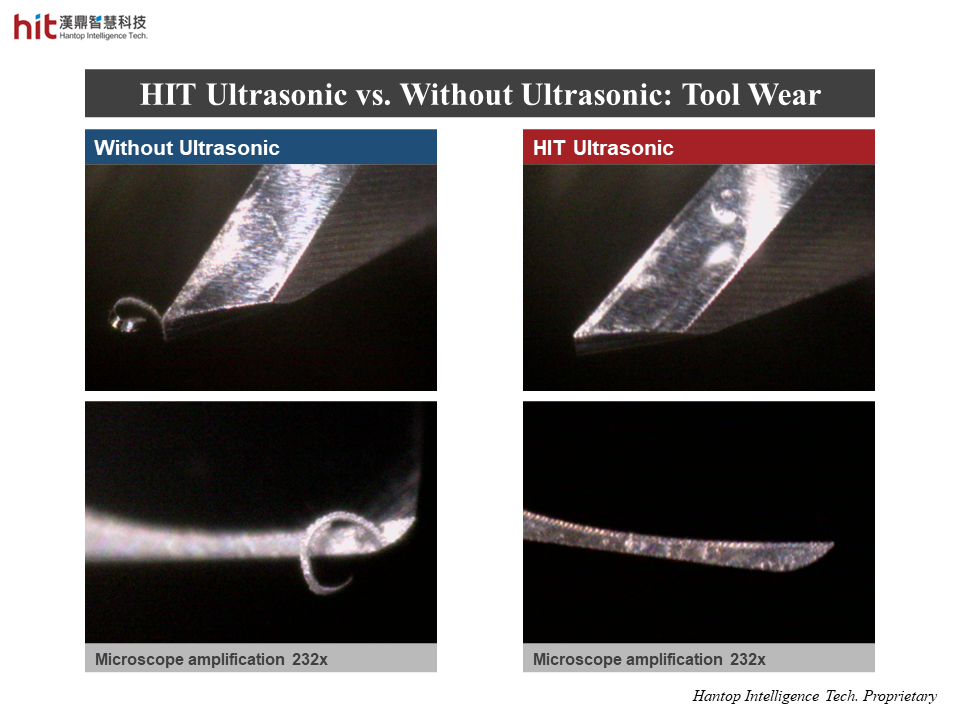

Aluminum Alloy (Al6061) Profile Milling (Micro-Conical Structure): Tool Life

(Figure 3. HIT ultrasonic-assisted profile milling of Al6061 aluminum alloy brought better chip evacuation, preventing the occurrence of BUE)

- In conventional machining, BUE on the tool caused high cutting forces. This not only damaged the surface of workpiece, but also caused serious tool wear.

- With HIT ultrasonic, better chip evacuation helped prevent BUE on the tool. There showed not much difference between the new tool and the used tool (with HIT ultrasonic).

HIT Ultrasonic Technology Achievements in Profile Milling of Aluminum Alloy (Al6061)

📈 Quality - surface was smooth without defects

⚙️ Tool Life - better chip evacuation prevents BUE on cutting tool