(Figure 1. the profile grinding of silicon carbide from the original raw material to the final workpiece)

HIT's Goal in Profile Grinding of Silicon Carbide (SiC)

Through the assistance of HIT ultrasonic-assisted machining technology, the goal is to reduce the total process time and tool wear, while maintaining acceptable workpiece quality in the profile grinding process of Silicon Carbide (SiC).

Ultrasonic-Assisted Profile Grinding of Silicon Carbide (SiC): Machining Results

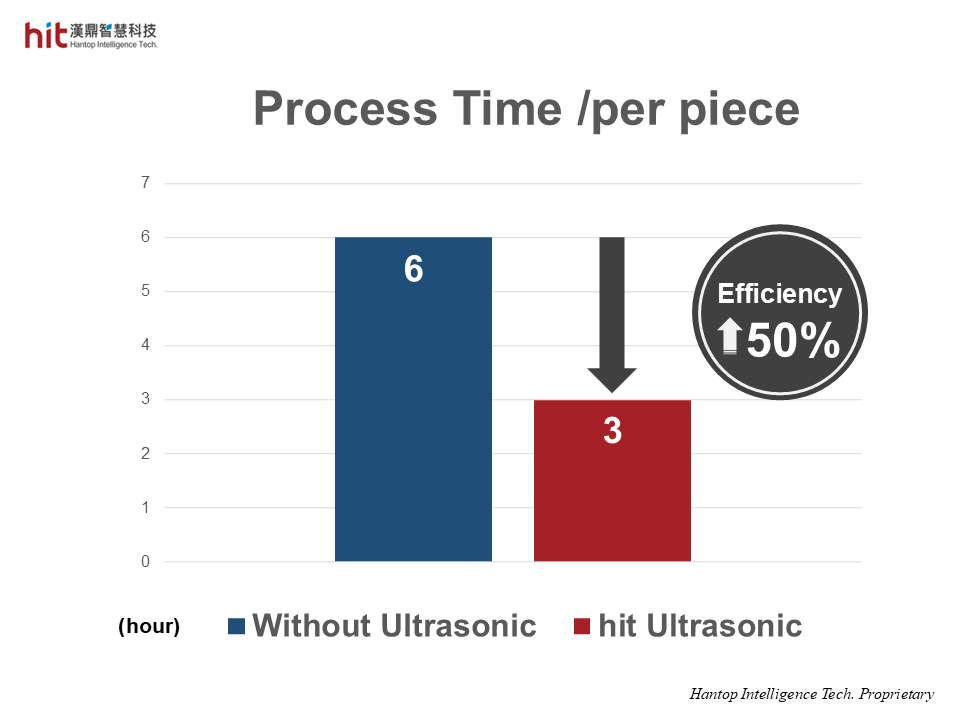

Profile Grinding of Silicon Carbide (SiC): Machining Efficiency

(Figure 2. with HIT ultrasonic-assisted profile grinding of silicon carbide, the overall machining efficiency was 50% higher)

- The high frequency micro-vibraiton of ultrasonic machining technology helps reduce grinding force, which allows for cutting parameters optimization.

- The process time per workpiece was reduced from 6 hours to 3 hours, representing a 50% improvement in machining efficiency. The machining process becomes significantly faster while maintaining high precision and stability.

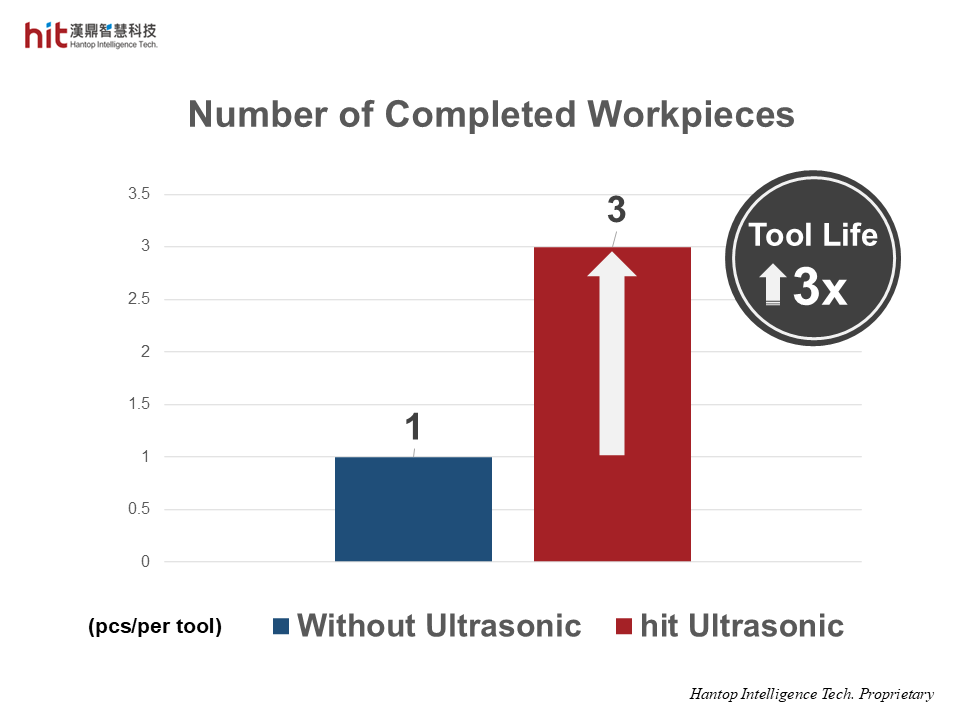

Profile Grinding of Silicon Carbide (SiC): Tool Life

(Figure 3. with HIT ultrasonic-assisted profile grinding of silicon carbide, the tool life was 3 times longer)

- The reduction of grinding force, along with better ceramic particles flushing, help reduce friction and heat generation, leading to less tool wear and more stable cutting conditions.

- This not only lowers tool replacement costs but also ensures consistent workpiece quality across a greater number of parts.

- The number of completed workpieces per tool increased from 1 to 3, achieving a three times extension in overall tool life.

HIT Ultrasonic Machining Technology Achievement in Profile Grinding of Silicon Carbide (SiC)

🕜 50% Higher Machining Efficiency

⚙️ 3x Longer Tool Life