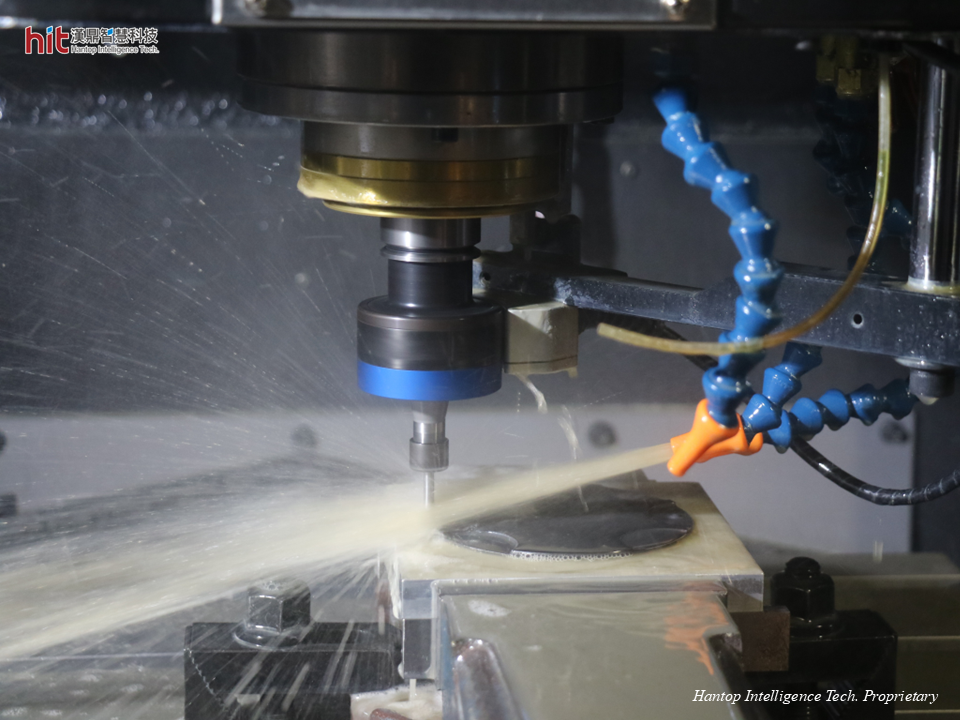

(Figure 1. HIT ultrasonic process solution applied to curved surface rough grinding of Silicon Carbide SiC)

HIT's Goal in Curved Surface (Rough) Grinding of Silicon Carbide (SiC)

Through the assistance of HIT ultrasonic-assisted machining technology, the goal is to reduce the total process time, while increasing workpiece quality by reducing the size of edge-cracks on the SiC workpiece.

Ultrasonic-Assisted Curved Surface (Rough) Grinding of Silicon Carbide (SiC): Machining Results

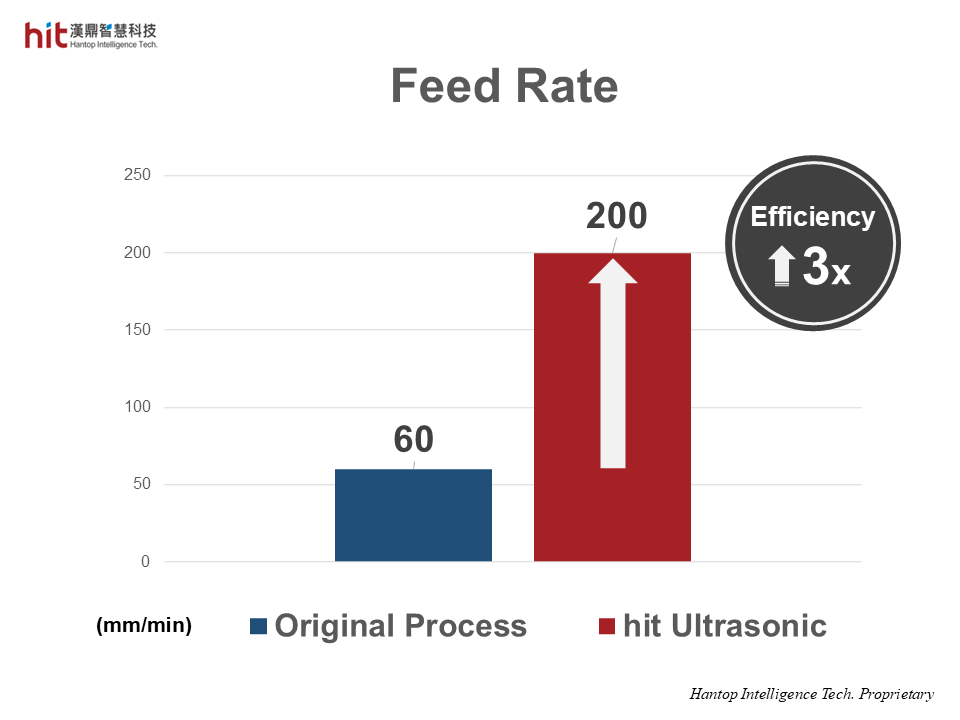

Curved Surface (Rough) Grinding of Silicon Carbide (SiC): Machining Efficiency

(Figure 2. HIT ultrasonic-assisted curved surface rough grinding of SiC brought 3x higher machining efficiency by increasing feed rate)

Adopting HIT Ultrasonic Process Solution for Rough Grinding of SiC:

- With HIT ultrasonic, the high frequency micro-vibration helped reduce grinding force.

- This allowed for enhancement in the machining parameters. The machining efficiency was increased after raising the feed rate 3x higher than the original process.

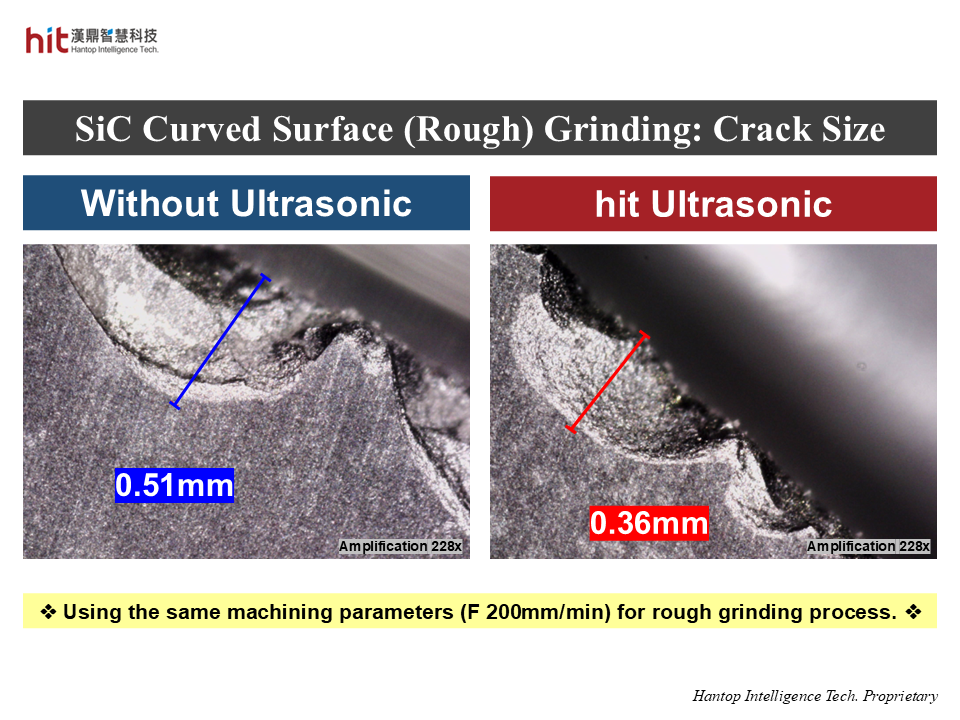

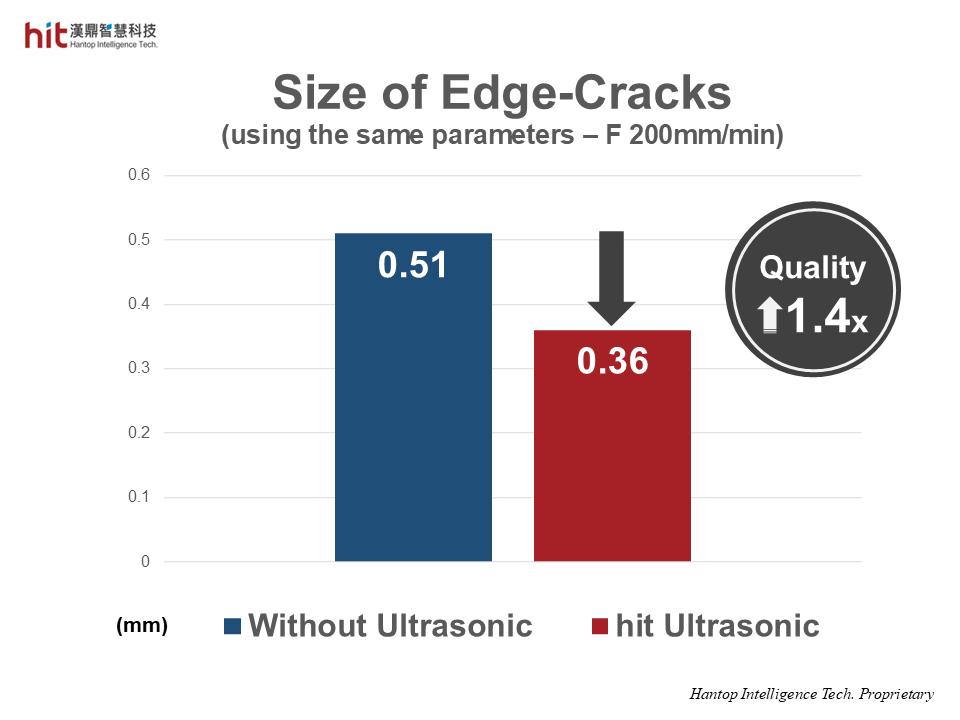

Curved Surface (Rough) Grinding of Silicon Carbide (SiC): Workpiece Quality

(Figure 3. HIT ultrasonic-assisted curved surface rough grinding of SiC helped reduce size of edge-cracks on the workpiece)

(Figure 4. HIT ultrasonic-assisted curved surface rough grinding of SiC brought better workpiece quality with smaller edge-cracks than that without ultrasonic)

- The reduction in grinding force helped control and reduce the size of edge-cracks on the SiC workpiece, which resulted in an improvement in workpiece quality.

- The crack size was 1.4x smaller than that without ultrasonic under the same machining parameters (F 200mm/min).

HIT Ultrasonic Machining Technology Achievements in Curved Surface (Rough) Grinding of Silicon Carbide (SiC)

🕜 Efficiency - 3x higher (enhancement of feed rate)

📈 Quality - 1.4x better (smaller edge-cracks)

Contact us now for an Ultrasonic Process Solution for SiC Curved Surface (Rough) Grinding,

or visit HIT's booth Q5344 at SEMICON Taiwan 2025 to learn more!

.png)