(Figure 1. HIT ultrasonic process solution applied to rough grinding of Aluminum Silicon Carbide (AlSiC) flip-chip lid)

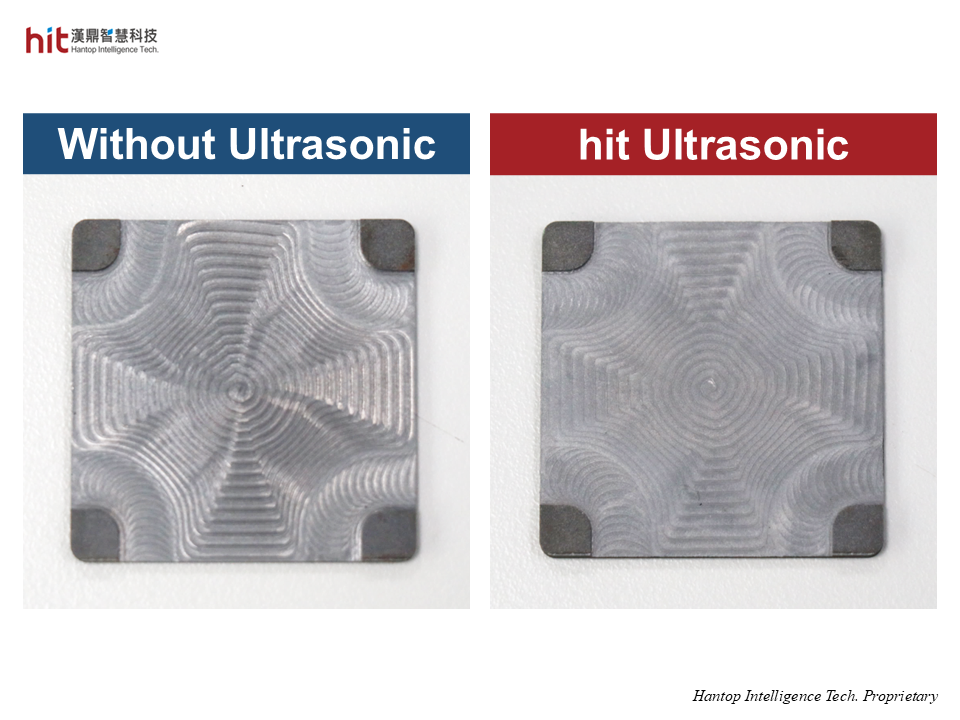

(Figure 2. HIT ultrasonic process solution applied to grinding of AlSiC flip-chip lid. Differences in surface quality are visible even in the rough grinding stage)

Ultrasonic Process Solution for Rough Grinding of Aluminum Silicon Carbide (AlSiC)

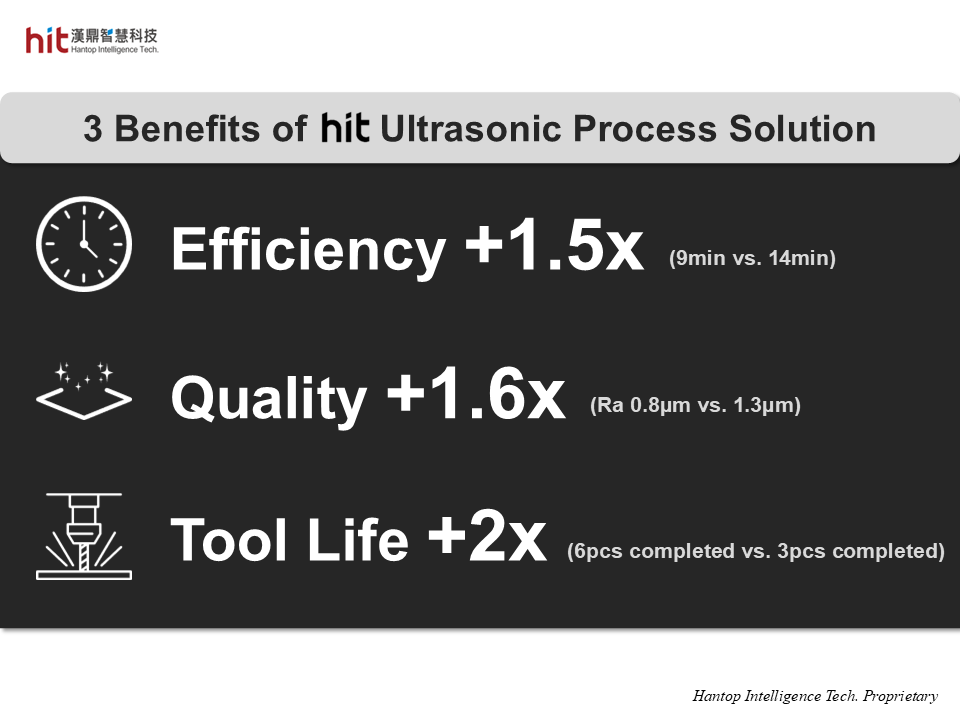

🔹High frequency micro-vibration of ultrasonic helps reduce grinding force and improves chip evacuation.

👍🏻 More space of enhancement for cutting parameters can reduce process time.

👍🏻 Better chip evacuation brings lower surface roughness and longer tool life.

🔹Ultrasonic Process Solution Package including:

✨ Cutting Parameters

✨ Tool Selection

✨ Process Configuration

Offering customers a comprehensive process development solution!

Ultrasonic Process Solution for Rough Grinding of Aluminum Silicon Carbide (AlSiC)

(Figure 3. HIT ultrasonic process solution applied to rough grinding of AlSiC flip-chip lid, improving machining efficiency, surface quality, and tool life)

Contact us now for an Ultrasonic Process Solution for AlSiC flip-chip lid,

or visit HIT's booth Q5344 at SEMICON Taiwan 2025 to learn more!

.png)