(Figure 1. HIT HSKE40 ultrasonic machining module was used on optimizing the micro-drilling process of silicon carbide with PCD drill)

HIT's Goal in Micro-Drilling of Silicon Carbide (SiC) with PCD Drill

The goal is to see how HIT HSKE40 ultrasonic machining module can help optimize the process of micro-drilling of Silicon Carbide (Sintered SiC) with PCD drill in efficiency, hole quality, and tool life.

Ultrasonic-Assisted Micro-Drilling of Silicon Carbide (SiC) with PCD Drill: Machining Results

Micro-Drilling of Silicon Carbide (SiC) with PCD Drill: Machining Efficiency

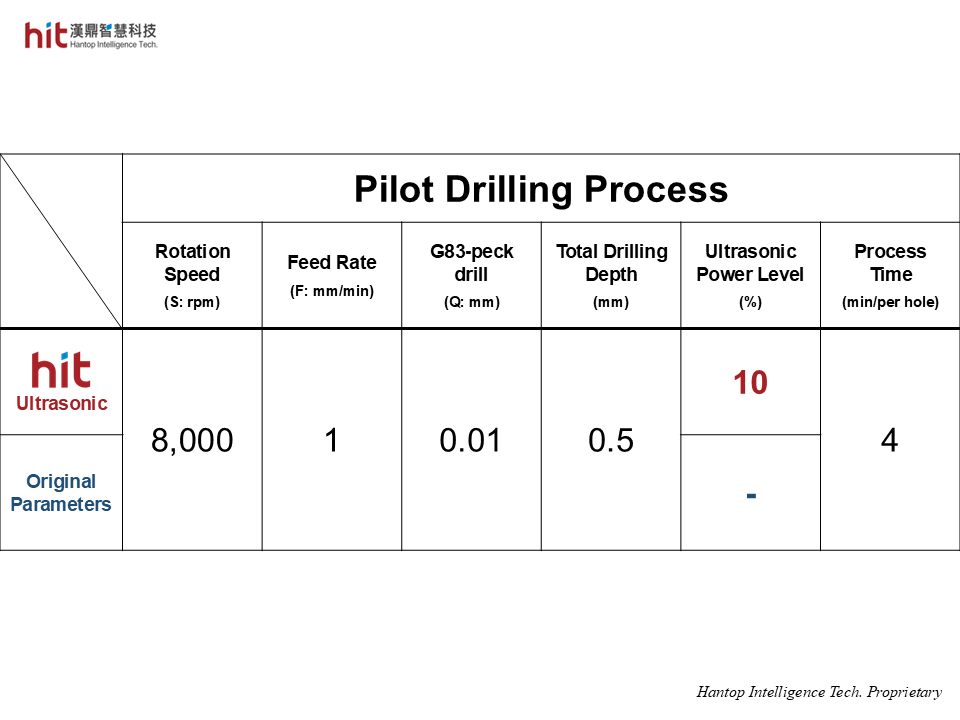

(Figure 2. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, ultrasonic should be on in pilot drilling process)

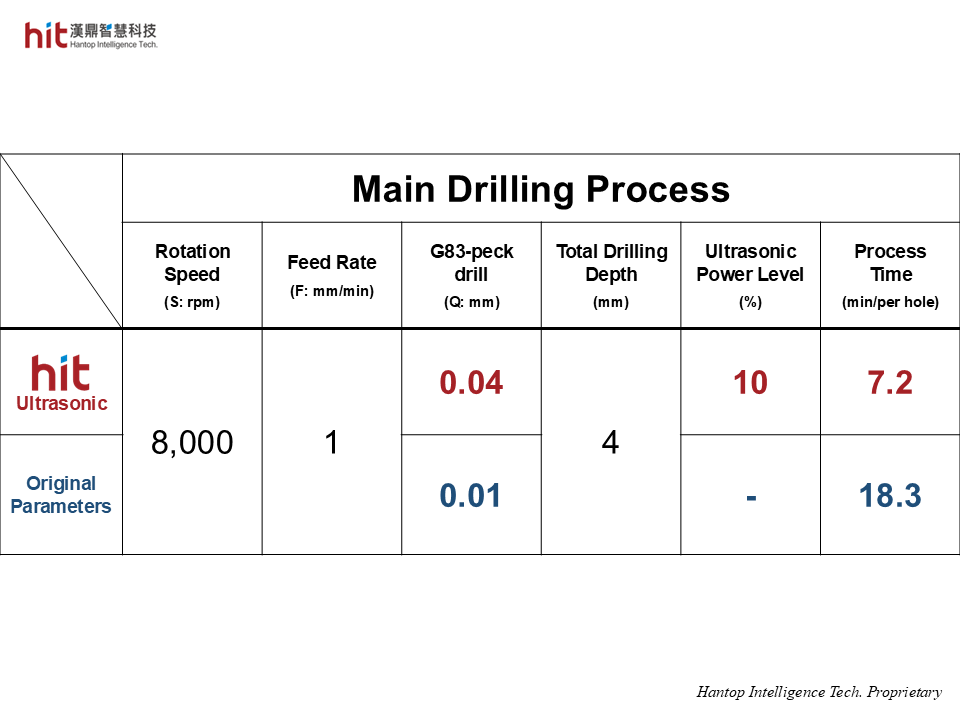

(Figure 3. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, Q-value in main drillilng process can be 4x higher, achieving an increase in total machining efficiency)

- To optimize the micro-drilling process of sintered SiC with PCD drill and HIT ultrasonic module, the high frequency micro-vibration helped reduce drilling force.

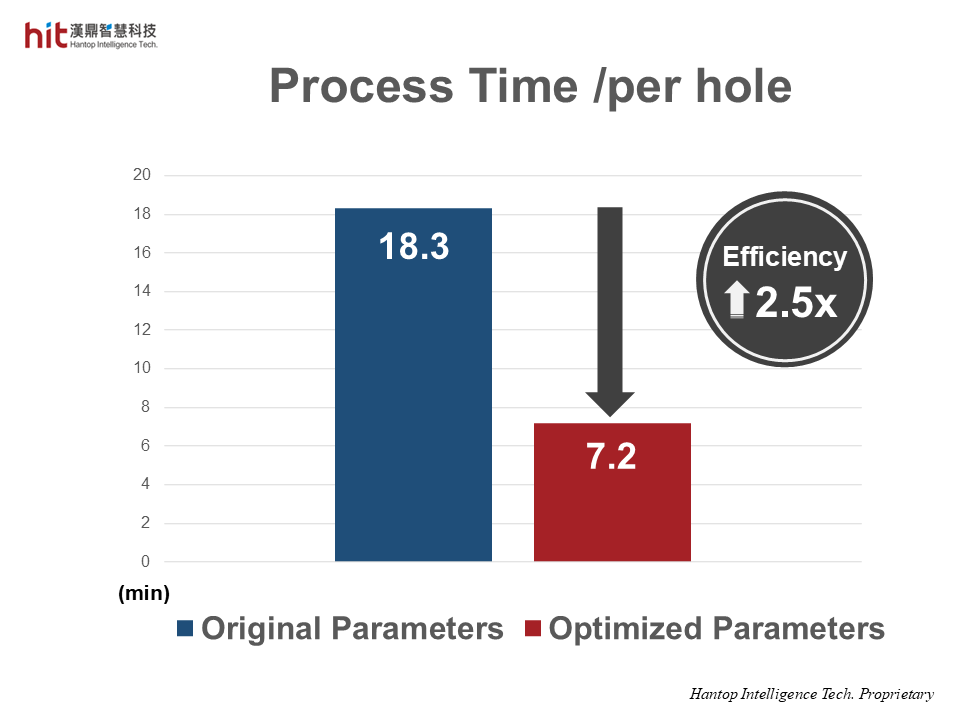

- This allowed the volume of peck drill (Q) in the main drilling process to be raised 4x higher (from 0.01 to 0.04mm), which brought 2.5x higher overall machining efficiency (process time shortened from 18.3 to 7.2 min/per hole).

(Figure 4. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, it helps reduce the process time per hole, which brings 2.5x higher machining efficiency)

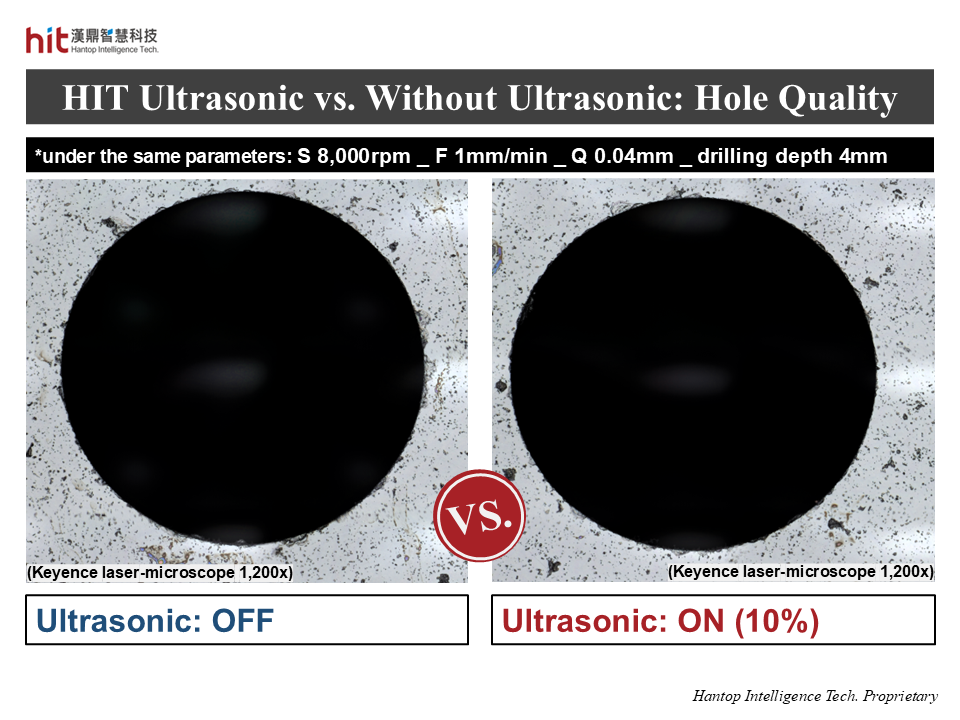

Micro-Drilling of Silicon Carbide (SiC) with PCD Drill: Hole Quality

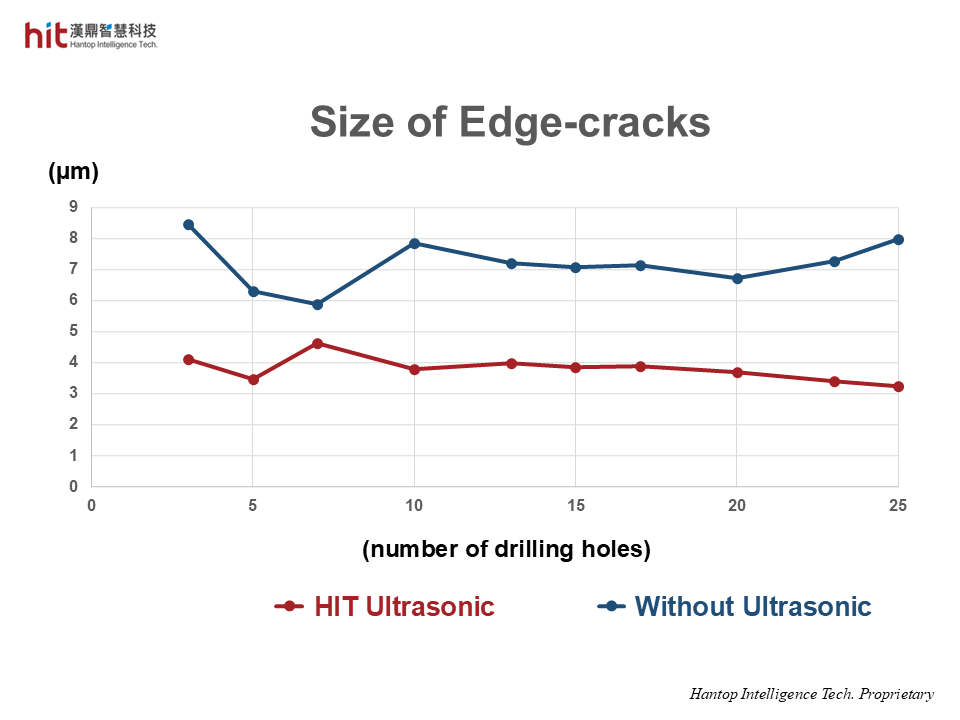

(Figure 5. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, the size of edge-cracks was smaller with the optimized parameters)

(Figure 6. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, the size of edge-cracks for each drilling hole was under 5µm)

- With HIT ultrasonic, the reduced drilling force helped stabilize the drilling process.

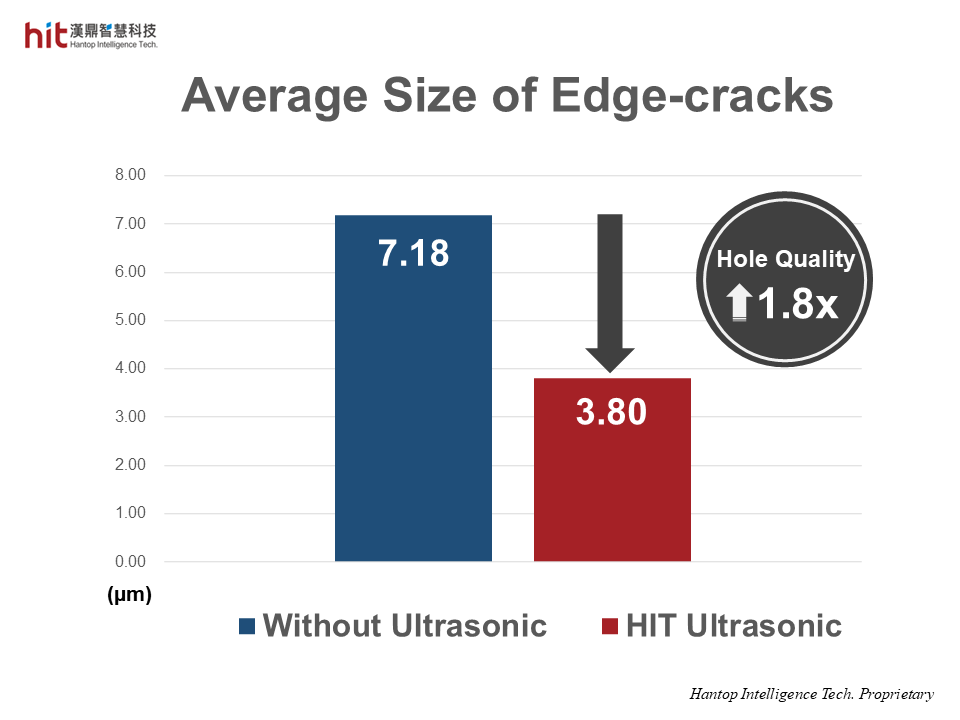

- Under 2.5x higher machining efficiency, the average size of edge-cracks was well-controlled and was 1.8x smaller thant that without ultrasonic under the same (optimized) parameters.

(Figure 7. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, the average size of edge-cracks was smaller, which brings 1.8x better hole quality)

Micro-Drilling of Silicon Carbide (SiC) with PCD Drill: Tool Life

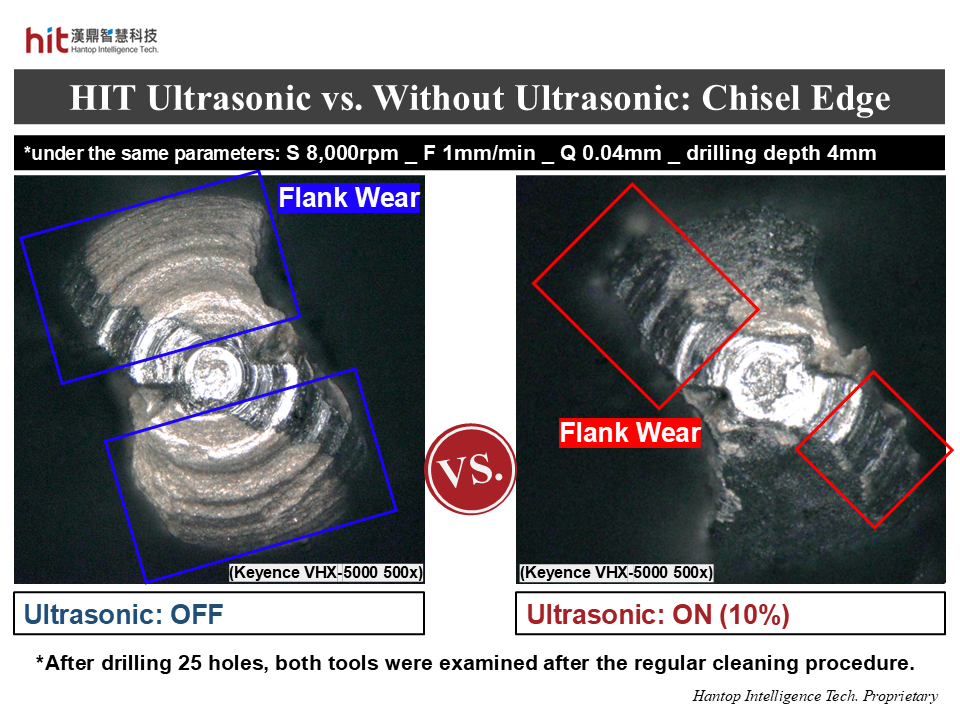

(Figure 8. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, tool wear observed from chisel edge was much smaller than that without ultrasonic)

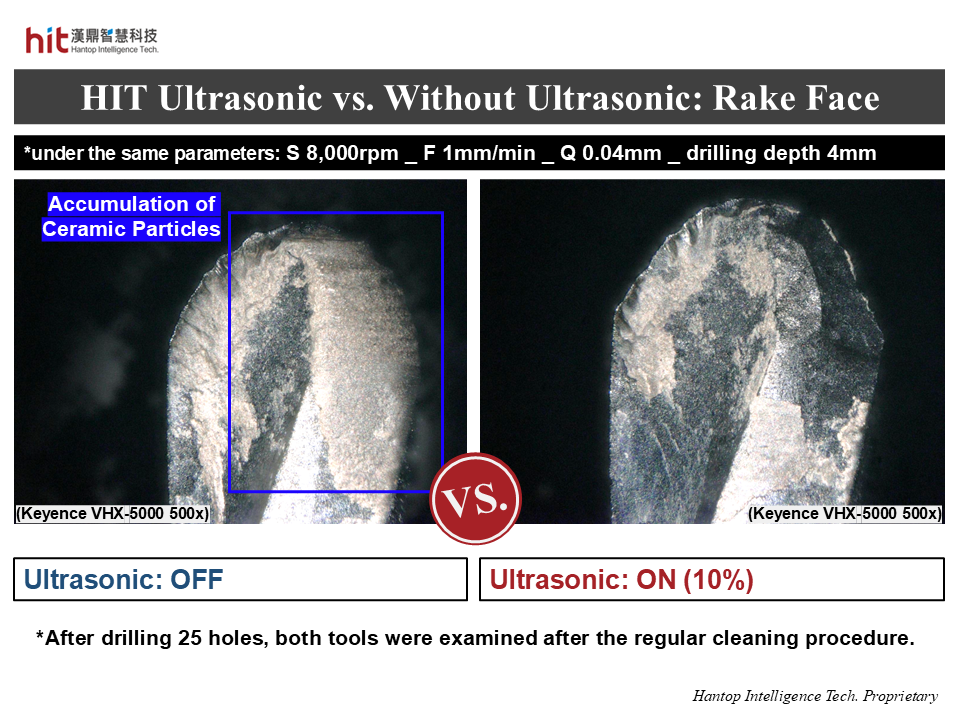

(Figure 9. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, accumulation of ceramic particles observed from rake face was less than that without ultrasonic)

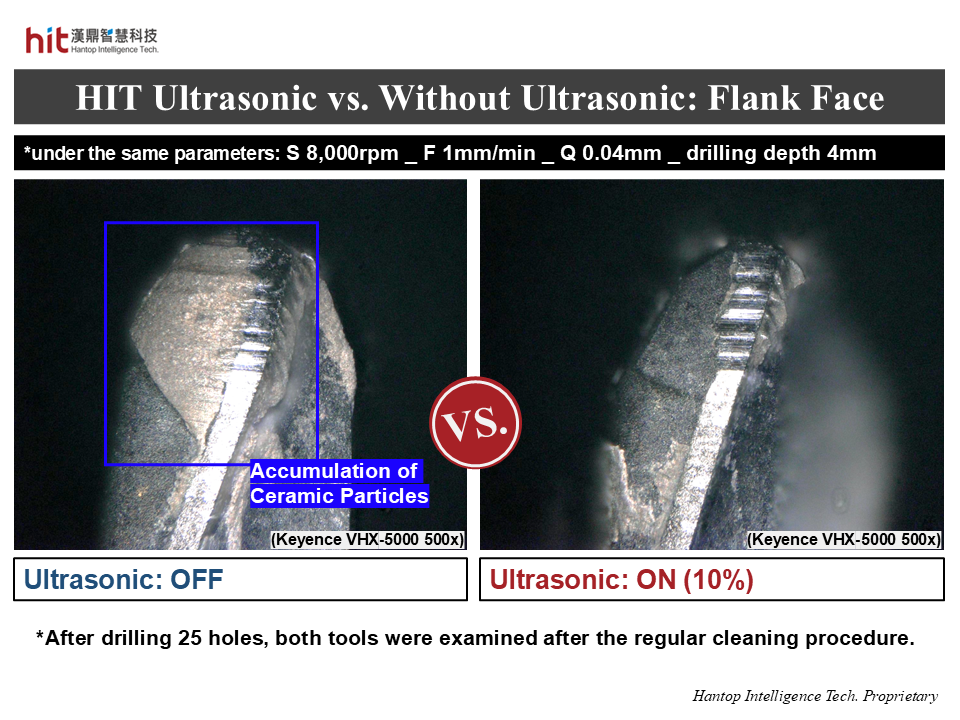

(Figure 10. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, accumulation of ceramic particles observed from flank face was less than that without ultrasonic)

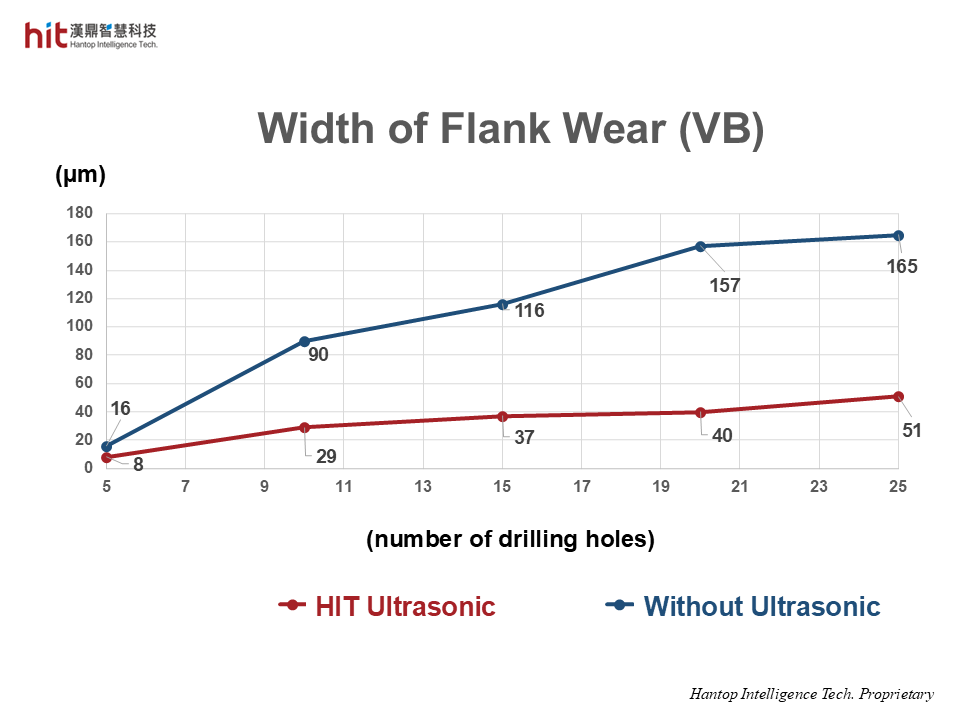

(Figure 11. with HIT HSKE40 ultrasonic machining module in micro-drilling of silicon carbide, the width of flank wear - VB after each drilling hole was smaller than that without ultrasonic)

- With HIT ultrasonic, the high frequency micro-vibration brought easier inflow of cutting fluid, which led to better ceramic particle flushing.

- Along with the reduced drilling force, the tool wear was 3.2x less than that without ultrasonic under the same (optimized) parameters.

HIT Ultrasonic Machining Technology Achievements in Micro-Drilling of Silicon Carbide (SiC) with PCD Drill

🕜 Efficiency - 2.5x higher with 4x higher Q-value (peck drilling)

📈 Hole Quality - 1.8 better with less edge-cracks

⚙️ Tool Wear - 3.2x less with better ceramic particles flushing and reduced drilling force