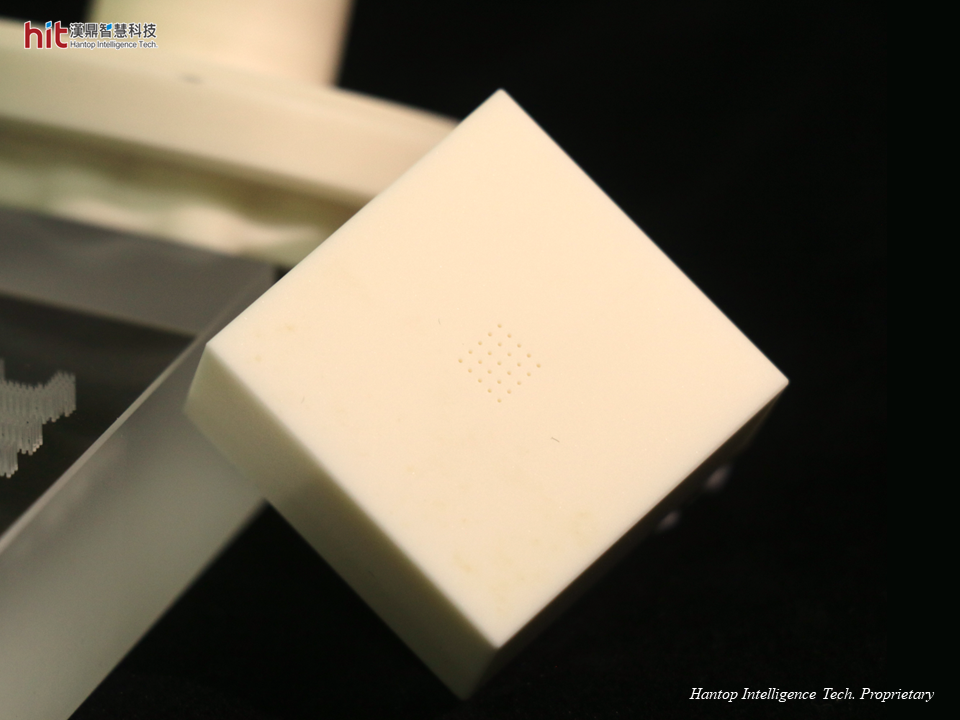

(Figure 1. HSK-E40 ultrasonic machining module was used on aluminum oxide ceramic micro-drilling)

(Figure 2. HIT ultrasonic-assisted machining of aluminum oxide ceramic micro-drilling workpiece)

HIT's Goal in Machining Aluminum Oxide (Al2O3) Ceramic

The goal is to see the benefits of HIT ultrasonic-assisted machining technology having on the micro-drilling of aluminum oxide ceramic.

Ultrasonic-Assisted Machining Aluminum Oxide (Al2O3) Ceramic Results

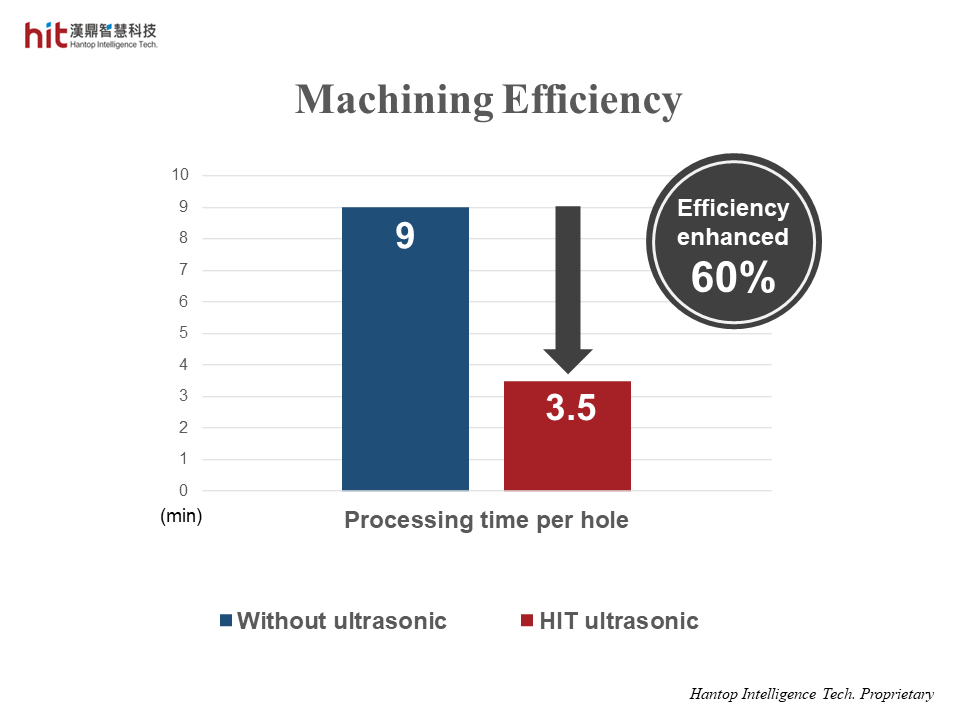

Aluminum Oxide (Al2O3) Ceramic Micro-Drilling : Machining Efficiency

(Figure 3. the machining efficiency was enhanced 60% with HIT Ultrasonic on micro-drilling of aluminum oxide ceramic)

- With HIT ultrasonic and the optimized machining parameters (S12,000rpm; F2mm/min), the processing time was reduced 60% from 9 minutes/per hole to 3.5 minutes/per hole.

- The reduction in cycle time helped enhance the machining efficiency by 60%.

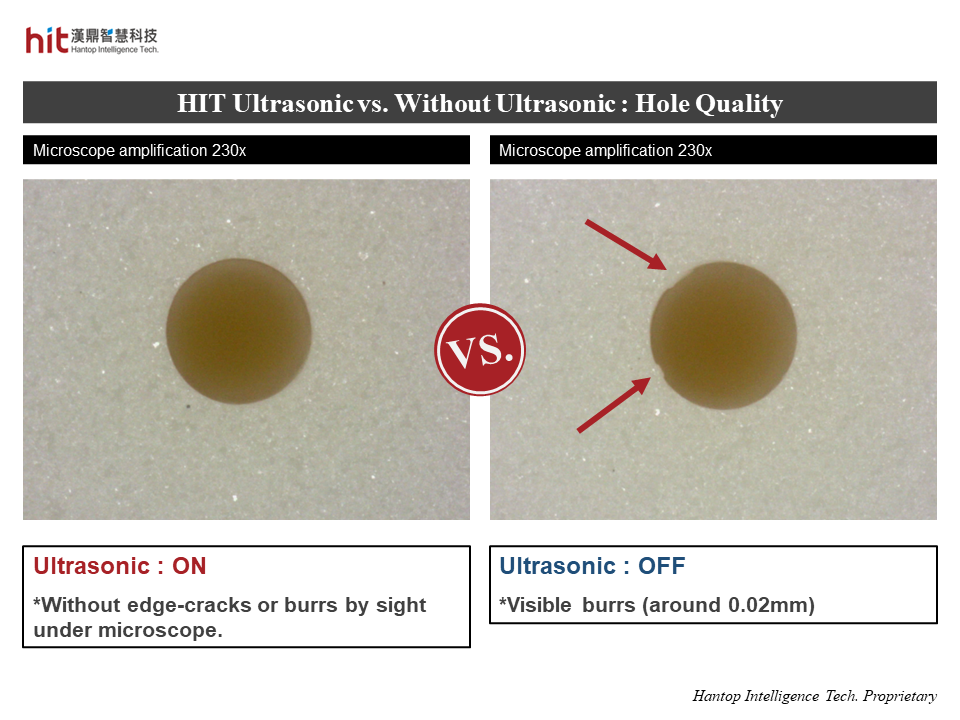

Aluminum Oxide (Al2O3) Ceramic Micro-Drilling : Hole Quality

(Figure 4. the comparison of hole quality between HIT Ultrasonic and Without Ultrasonic on micro-drilling of aluminum oxide ceramic)

- With HIT Ultrasonic, it helped maintain high hole quality workpieces with no obvious edge-cracks or burrs on the drilling holes by sight under microscope.

- The reduction in cutting force not only helped with better hole quality, but also precisional repeatability of the drilling holes.

HIT Ultrasonic Machining Technology Achievements

🕜 Efficiency - enhanced 60%

📈 Quality - without edge-cracks or burrs by sight

⚙️ Tool Life - well-maintained