HIT's Goal in Drilling of Carbon Ceramic Brake Disc (CCB)

The goal is to see how HIT HBT40 ultrasonic machining module can help optimize the process of drilling of carbon ceramic brake disc (CCB) in efficiency, hole quality, and tool life.

Ultrasonic-Assisted Drilling of Carbon Ceramic Brake Disc (CCB): Machining Results

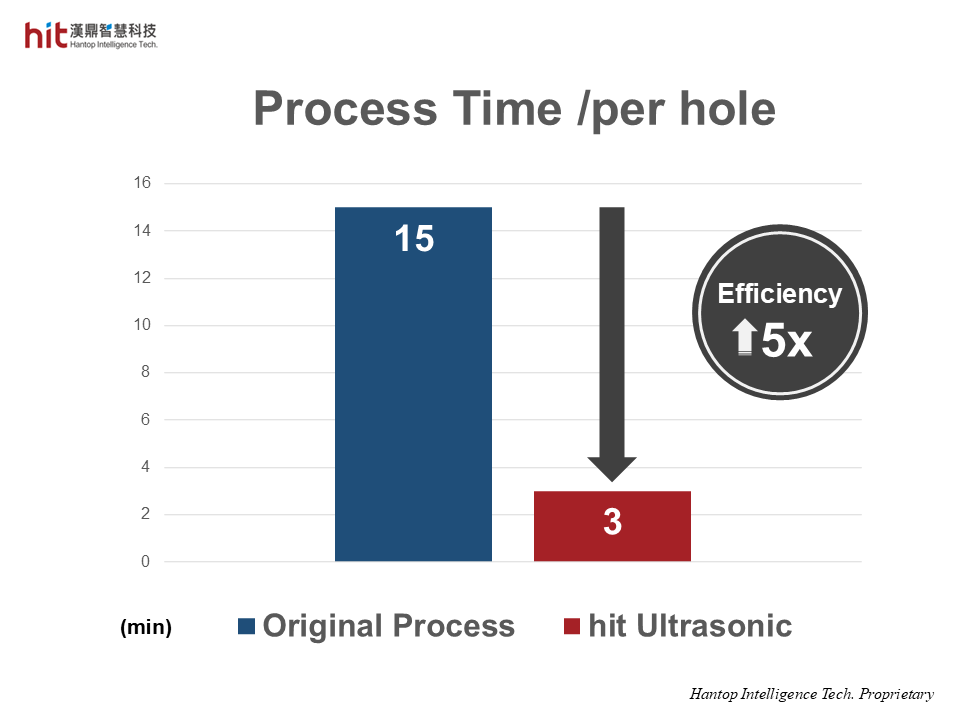

Drilling of Carbon Ceramic Brake Disc (CCB): Machining Efficiency

(Figure 1. with HIT HBT40 ultrasonic machining module in drilling of carbon ceramic brake disc, it helps reduce the process time per hole, which brings 5x higher machining efficiency)

- By using HIT's ultrasonic machining module to assist in the drilling process of carbon ceramic brake disc (CCB), the ultrasonic vibration provides the tool with high frequency micro-vibration. During machining, the tool intermittently impacts the workpiece, creating space for cooling and chip evacuation, which helps reduce drilling force.

- The reduction in drilling force allows for optimization of machining parameters, effectively shortening the process time per hole and achieving a 5x higher machining efficiency.

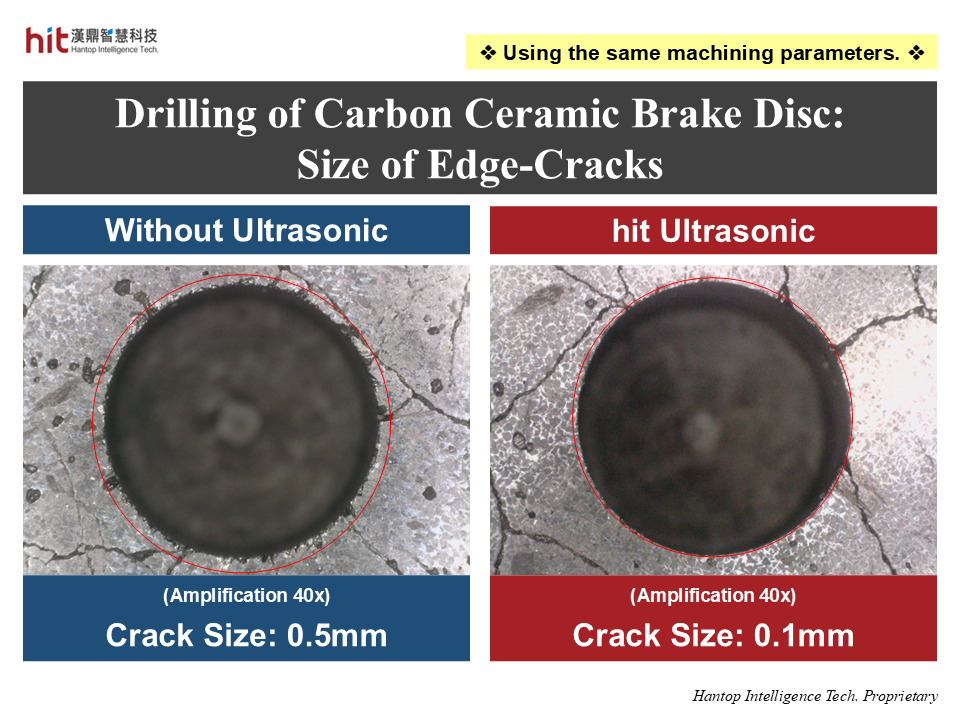

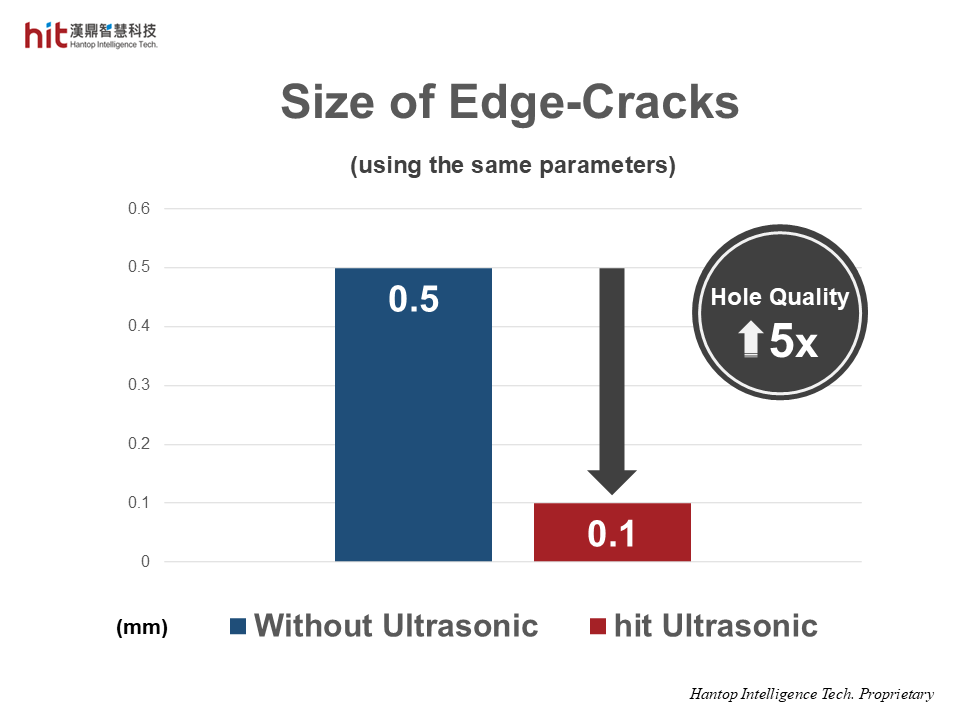

Drilling of Carbon Ceramic Brake Disc (CCB): Hole Quality

(Figure 2. with HIT HBT40 ultrasonic machining module in drilling of carbon ceramic brake disc, it helps reduce the size of edge-cracks compared to that without ultrasonic)

(Figure 3. with HIT HBT40 ultrasonic machining module in drilling of carbon ceramic brake disc, the size of edge-cracks became smaller than that without ultrasonic, which brings 5x better hole quality)

- The high frequency micro-vibration generated by ultrasonic help further reduce drilling force. The tool's impacts on the workpiece become smaller yet more frequent, significantly decreasing the size of edge-cracks around the drilled holes.

- The reduction of crack size leads to a 5x better hole quality.

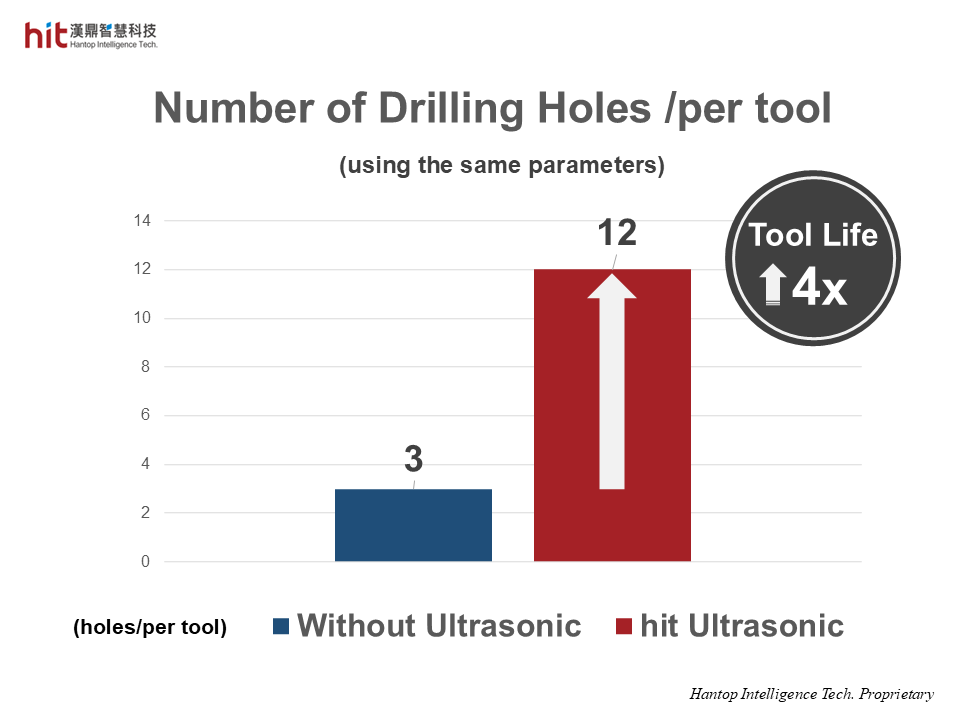

Drilling of Carbon Ceramic Brake Disc (CCB): Tool Life

(Figure 4. with HIT HBT40 ultrasonic machining module in drilling of carbon ceramic brake disc, the number of drilling holes is more than that without ultrasonic, which brings 4x longer tool life)

- Lower drilling force not only reduces the size of edge-cracks, but also provides better cooling and chip evacuation, which greatly reduces tool wear.

- Compared with the process without ultrasonic (using the same machining parameters), the number of drilling holes completed per tool increases, and the overall tool life is extended by 4x.

HIT Ultrasonic Machining Technology Achievements in Drilling of Carbon Ceramic Brake Disc (CCB)

🕜 Efficiency - 5x higher (much less process time per hole)

📈 Hole Quality - 5x better (much smaller crack size)

⚙️ Tool Life - 4x longer (more drilling holes per tool)

💡 Check out more successful case study: Surface Grinding of Carbon Ceramic Brake Disc (CCB)