2024/09/12

HIT Ultrasonic @ SEMICON TW 2024 | Optimized Solution for Machining of Semiconductor Advanced-Material

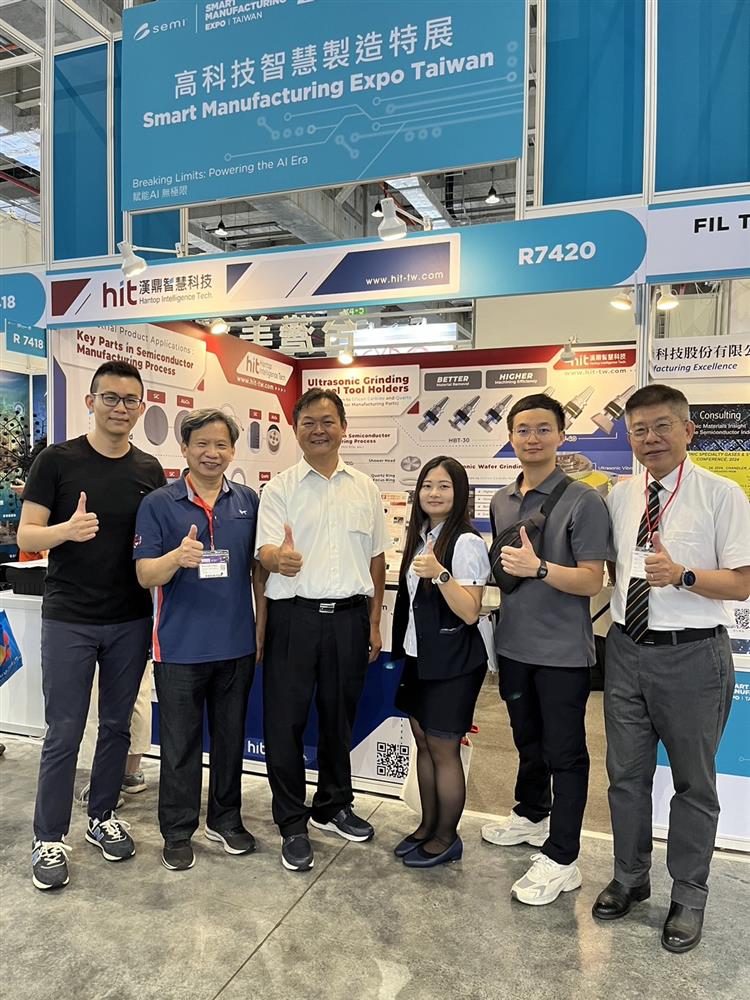

The three-day SEMICON Taiwan 2024 exhibition (Sep. 4th to 6th) successfully concluded! This year's event set another new record in scale, spanning across Taipei TaiNEX Hall 1 & 2, with the theme "Breaking Limits: Powering the AI Era."

In response to market trends, specialized zones were created for AI semiconductor technologies, silicon photonics, and high-tech smart manufacturing. The exhibition attracted nearly 90,000 visitors over three days, showcasing the spirit of "Semiconductors Light Up Taiwan, Taiwan Shines on the World!"

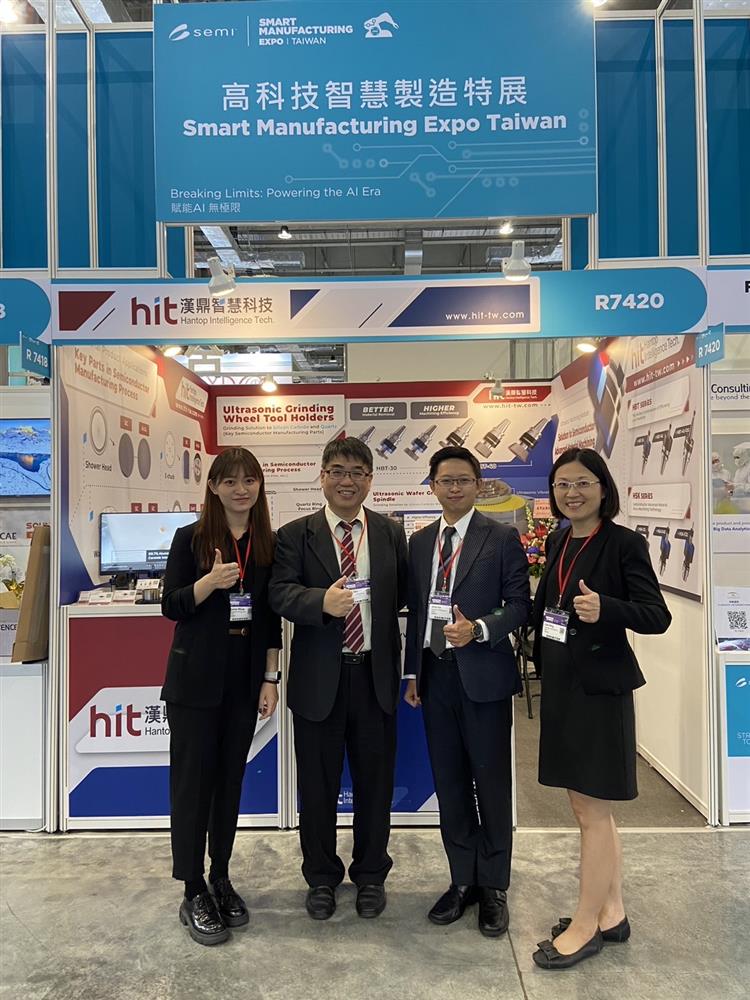

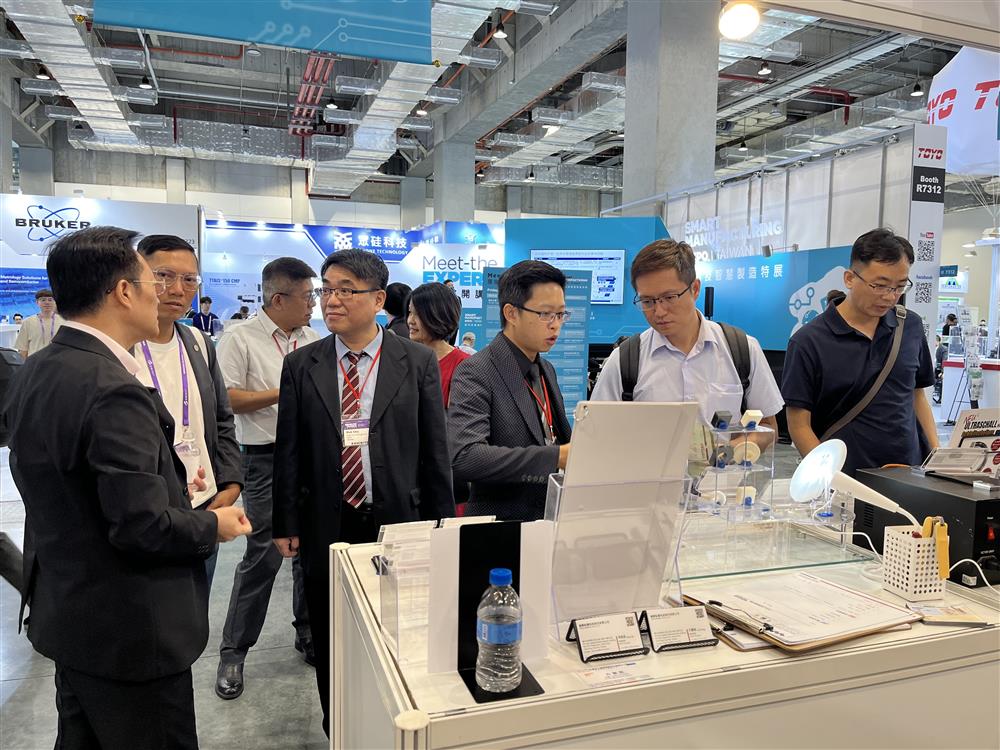

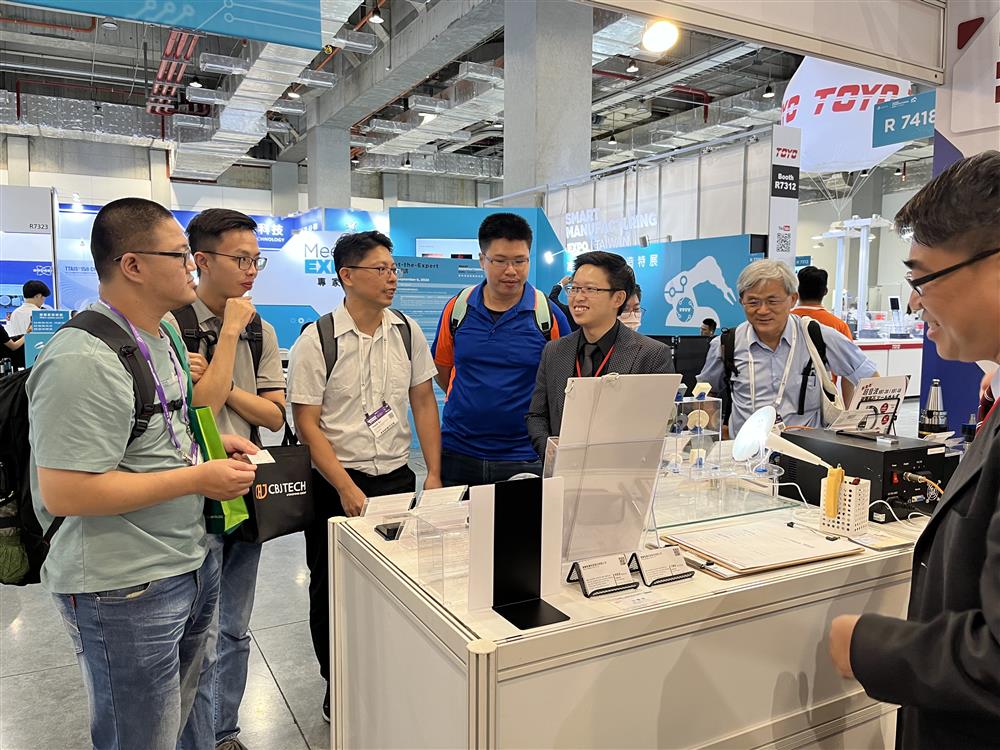

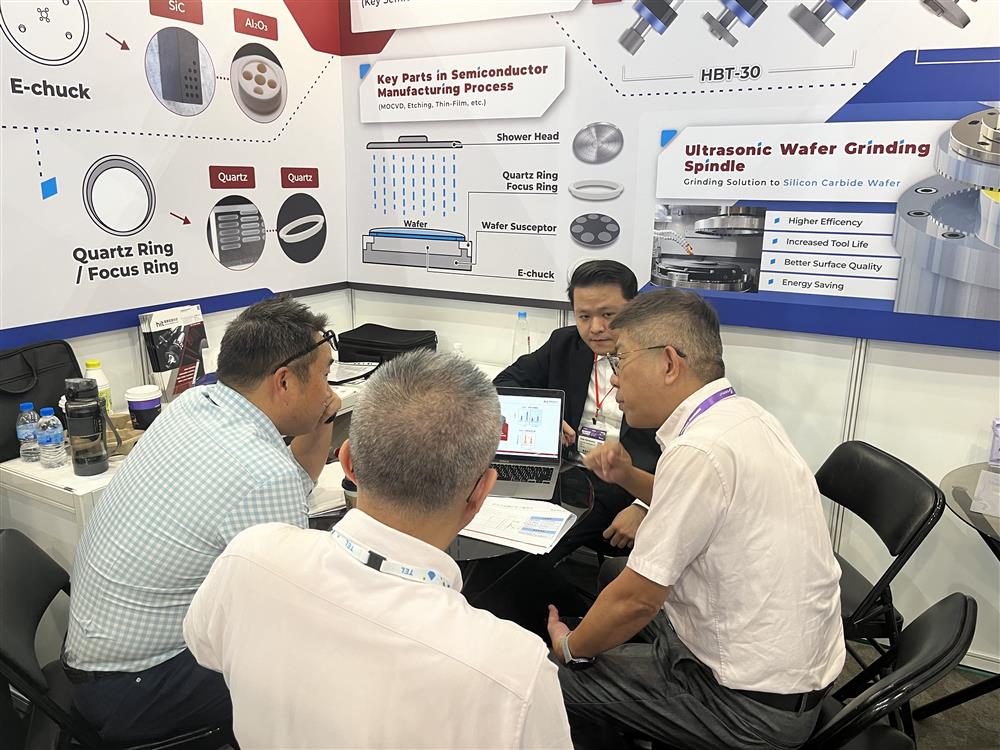

【HIT@SEMICON Taiwan 2024: Visiting Crowd at HIT Booth】

(Figure 1. Hantop Intelligence Tech. exhibitted in SEMICON Taiwan 2024)

At this year's event, HIT not only displayed its main product Ultrasonic-Assisted Machining Module, providing optimized machining solutions for consumable parts (such as ceramic showerheads, E-chucks / Electrostatic Chucks, and wafer susceptors) used in semiconductor manufacturing equipment (such as etching machines).

HIT also promoted its upcoming new products at the event:

- Ultrasonic Grinding Wheel Toolholder: Designed for CNC grinding process, specifically for grinding annular parts in semiconductor manufacturing equipment (such as Quartz/Focus Rings). It helps enhance machining efficiency by 2 to 3 times and increase the MRR (Material Removal Rate) by more than 3 times.

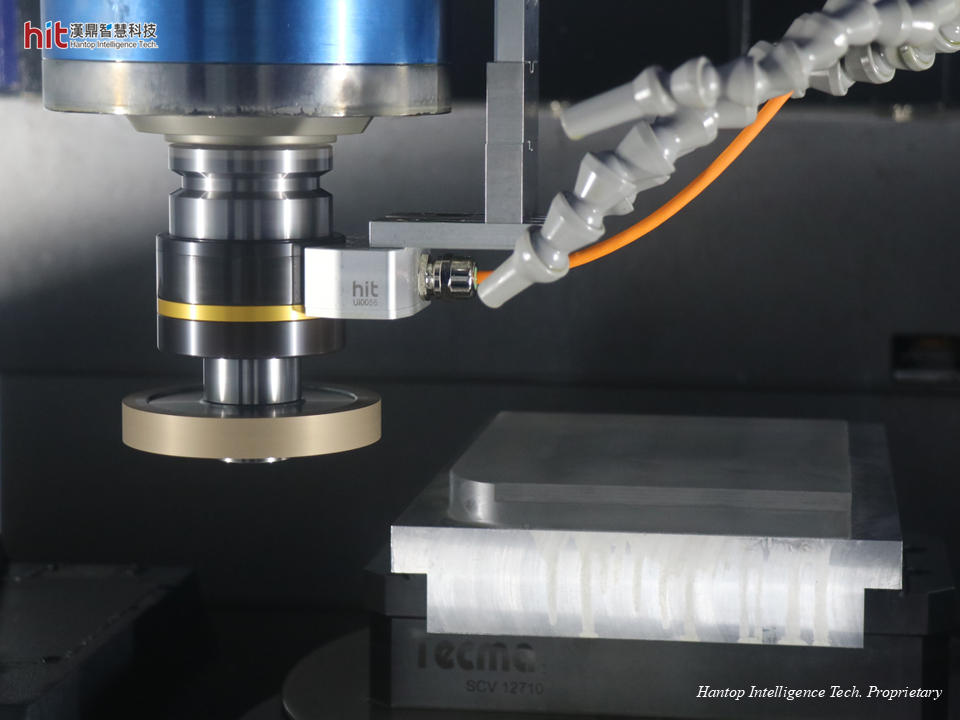

(Figure 2. HIT HBT-40 Ultrasonic Grinding Wheel Toolholder was used on side grinding of quartz glass)

- Ultrasonic Electroplated Diamond Grinding Tool: Suited for profile grinding of aluminum oxide ceramic materials, it features an exclusive custom formulation that perfectly complements ultrasonic vibration-assisted machining technology, doubling overall machining efficiency.

(Figure 3. HIT ultrasonic electroplated diamond grinding tool is suitable for grinding of alumina ceramic)

The introduction of these new products is expected to further enhance the benefits of grinding ceramic materials. By improving overall machining efficiency and reducing tool wear, these products are expected to increase productivity and reduce production costs, serving as a secret weapon for entering the supply chain of semiconductor industry!

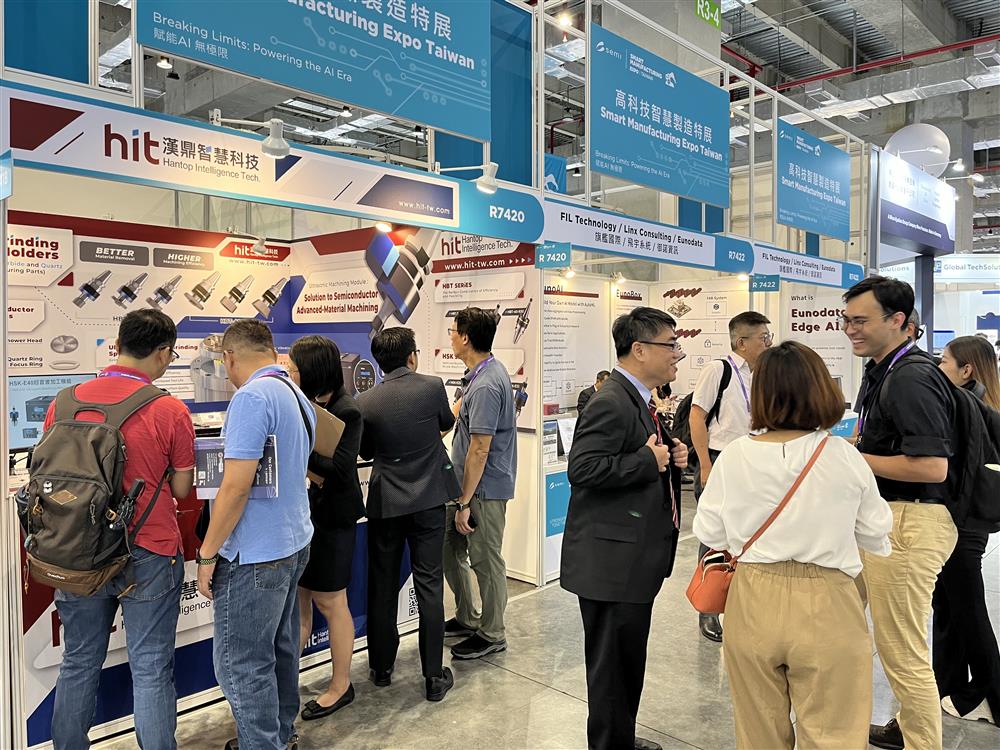

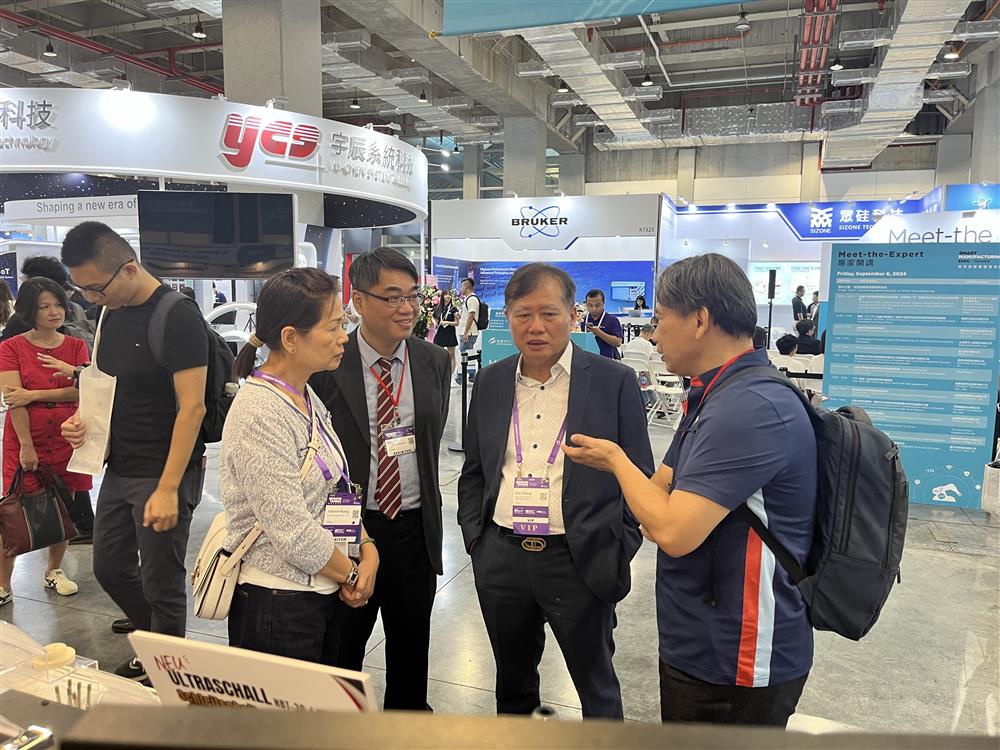

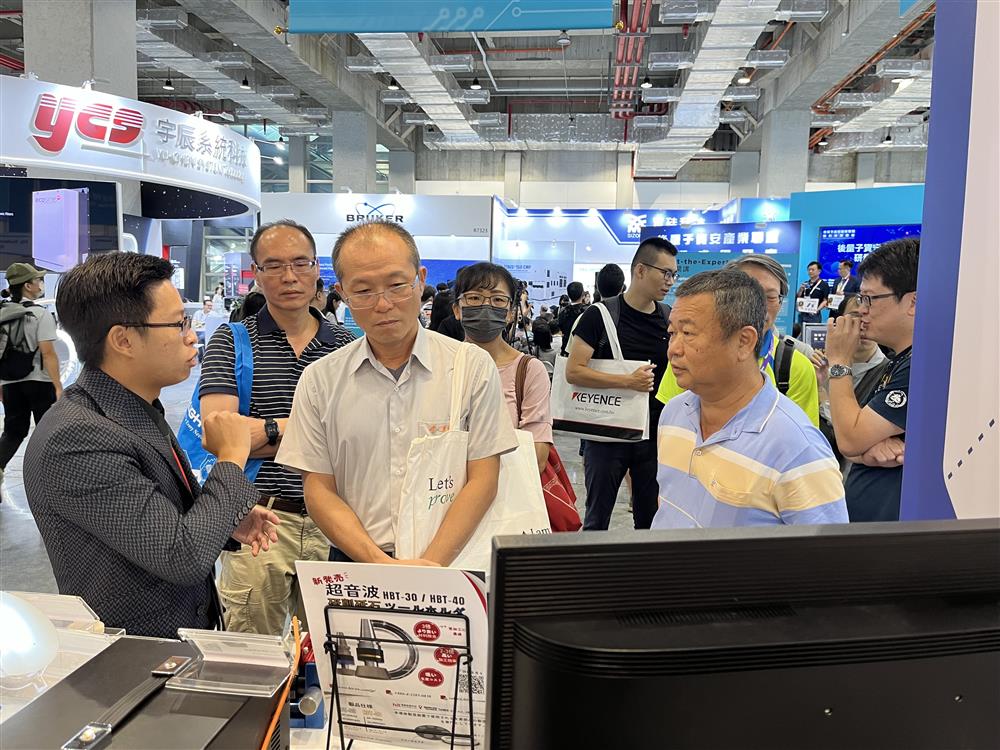

(Figure 4. Continuous flow of visitors came to HIT booth to learn about ultrasonic-assisted machining products during SEMICON Taiwan 2024)

(Figure 5. Not only CNC machine tool suppliers, but also manufacturing companies that provide semiconductor consumable parts and companies that provide semicondutor equipment came visit HIT to know more about ultrasonic products)

【HIT@SEMICON Taiwan 2024: Smart Manufacturing Journey - Meet-the-Expert】

On the final day of the event, HIT's R&D Director was specially invited to participate in the "Meet-the-Expert" seminar held in the High-Tech Smart Manufacturing area. The presentation, titled "Application of Ultrasonic-Assisted Machining Technology in Semiconductors", focused on sharing HIT's ultrasonic vibration-assisted cutting mechanism and the upcoming new products. These innovations are set to bring more advanced, energy-efficient, and multi-benefit machining process optimization solutions for the consumable parts used in semiconductor manufacturing equipment.

(Figure 6. SEMICON Taiwan 2024 Meet-the-Expert: Benefits of HIT ultrasonic-assisted micro-drilling on key parts used in semiconductor manufacturing equipment)

(Figure 7. SEMICON Taiwan 2024 Meet-the-Expert: HIT new product - ultrasonic wafer grinding spindle is expected to greatly reduce wear on the wheel, which helps cut down production costs)

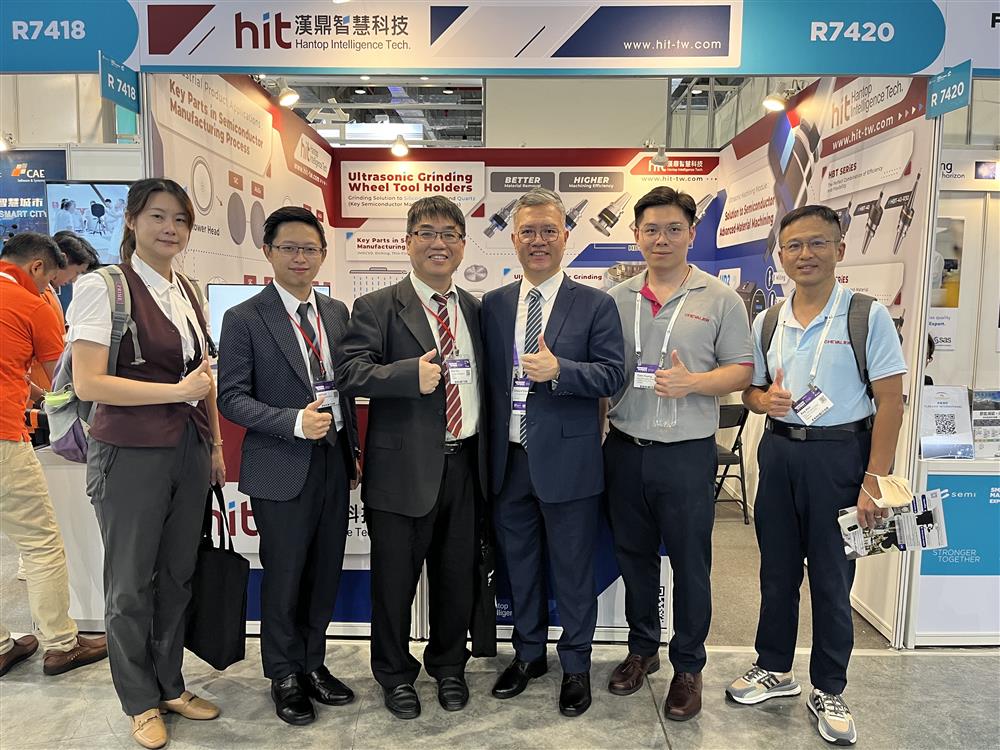

【HIT@SEMICON Taiwan 2024: Thanks all the Industrial Experts for Visiting!】

HIT sincerely thanks all the visitors during the exhibition!

HIT will deeply treasure the feedback from customers and business partners and turn this encouragement into motivation for growth.🌱

HIT aims to bring more innovative and diverse product applications this year, while continuing to provide high-quality products and dedicated professional services to customers both domestically and internationally.

HIT sincerely invites all industry experts to continue following and supporting us!💝

(Figure 8. SEMICON Taiwan 2024 - Thanks TOCHANCE Technology Co., Ltd. for the graceful flower)

(Figure 9. SEMICON Taiwan 2024 - Thanks CHEVALIER - Falcon Machine Tools Co., Ltd. for leading its sales team to visit HIT and learn more about new ultrasonic products and applications)

(Figure 10. SEMICON Taiwan 2024 - Thanks HAMAGAWA - Bin Chuan Enterprise Co., Ltd. and SHIBA R&D 株式会社 芝技研 for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 11. SEMICON Taiwan 2024 - Thanks YCM - Yeong Chin Machinery Industries Co., Ltd. for leading its engineering & application team to visit HIT and learn more about new ultrasonic products and applications)

(Figure 12. SEMICON Taiwan 2024 - Thanks Arktek Co., Ltd. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 13. SEMICON Taiwan 2024 - Thanks Royal Precision Tool Corporation for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 14. SEMICON Taiwan 2024 - Thanks Hartford for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 15. SEMICON Taiwan 2024 - Thanks AWEA Mechantronic Co., Ltd. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 16. SEMICON Taiwan 2024 - Thanks VIS - Vanguard International Semiconductor Corporation for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 17. SEMICON Taiwan 2024 - Thanks FitTech Co., Ltd. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 18. SEMICON Taiwan 2024 - Thanks Wellthin Technology Ltd. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 19. SEMICON Taiwan 2024 - Thanks High Energy E-Beam Tech. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 20. SEMICON Taiwan 2024 - Thanks TEL - Tokyo Electron Limited for visiting HIT to learn more about new ultrasonic products and technical application for future cooperation)

(Figure 21. SEMICON Taiwan 2024 - Thanks Tech PLUS Precision Machinery Industry Co., LTD for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 22. SEMICON Taiwan 2024 - Thanks Chin Ming Precision Tools Co., Ltd. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 23. SEMICON Taiwan 2024 - Thanks E&R Engineering Corporation for visiting HIT to learn more about new ultrasonic products and technical applications for future cooperation)

(Figure 24. SEMICON Taiwan 2024 - Thanks Champmill Precision LTD. for visiting HIT to learn more about new ultrasonic products and applications)

(Figure 25. SEMICON Taiwan 2024 - Thanks for visitor from India to learn about ultrasonic products and applications)

(Figure 26. SEMICON Taiwan 2024 - Thanks for visitor from Malaysia to learn about ultrasonic products and applications)

(Figure 27. SEMICON Taiwan 2024 - HIT participated in the Smart Manufacturing Industry Networking Luncheon during the event to dine and exchange ideas with industrial experts)

(Figure 28. SEMICON Taiwan 2024 - HIT prepared a little thoughtful gift for visitors that came to our booth as a way to show gratitude for their support)

【HIT@SEMICON Taiwan 2024: Stay Tuned for New Ultrasonic Optimizational Solution for Machining of Key Parts used in Semiconductor Manufacturing Equipment】

---- As the Secret Weapon to Enter the Supply Chain of Semiconductor Industry ----

🔹 Best applied in the rough grinding of semiconductor advanced-material

🔹 Overall Machining Efficiency: 2 - 3x Higher

🔹 Material Removal Rate (MRR): More than 3x Higher

🔹 Great reduction in production costs and energy consumption

.png)

👍🏻 2x Higher Machining Efficiency 👍🏻 3x Better Workpiece Quality 👍🏻 Great Reduction in Tool Wear

HIT utilized HSK-E40 ultrasonic machining module for profile grinding of aluminum oxide (Al2O3) ceramic. Along with Ultrasonic Electroplated Diamond Grinding Tool, the high frequency micro-vibration of ultrasonic brought easier removal of ceramic particles. The reduction in grinding force and tool wear not only contributed to great workpiece quality but also allowed for an increase in feed rate, which enhanced 2x of the overall machining efficiency.

💡 Learn more about HIT ultrasonic optimized solution for machining of the advanced-materials (technical ceramics, quartz, glass, stainless steel, etc.) applied in semiconductor industry:

-

Hantop Intelligence Tech.

Optimized Solution for Machining of Semiconductor Advanced-Material with Ultrasonic-Assisted Machining Module

Optimized Solution for Machining of Semiconductor Advanced-Material with Ultrasonic-Assisted Machining Module

+886-4-2285-0838

+886-4-2285-0838

sales@hit-tw.com

sales@hit-tw.com

To improve the machining efficiency, workpiece quality, and tool life, by following the trend of ESG, feel free to CONTACT US.